FOXBORO P0903NU is a high-performance system module launched by Foxboro Corporation in the field of industrial automation. As an important component of the FOXBORO I/A Series distributed control system, its core function is to achieve reliable communication transfer, signal isolation processing, and data distribution between on-site equipment and upper level control systems, providing stable data transmission guarantee for precise control of industrial production processes. This module, with its compact modular design, powerful anti-interference ability, and flexible compatibility, can seamlessly adapt to complex industrial scenarios such as power, petrochemicals, and metallurgy, effectively solving the pain points of traditional system modules in signal transmission stability, multi device compatibility, and other aspects. It is a key equipment for building efficient industrial control networks.

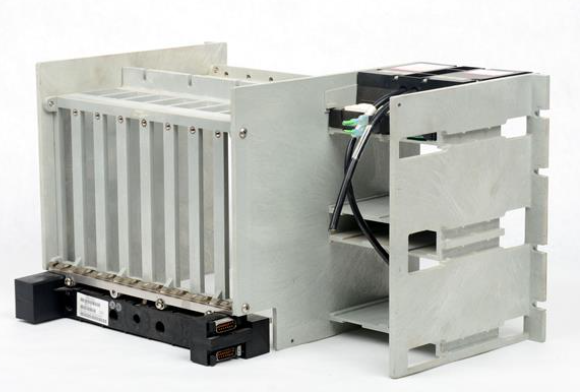

FOXBORO P0903NU system module

Product Overview

FOXBORO P0903NU is a high-performance system module launched by Foxboro Corporation in the field of industrial automation. As an important component of the FOXBORO I/A Series distributed control system, its core function is to achieve reliable communication transfer, signal isolation processing, and data distribution between on-site equipment and upper level control systems, providing stable data transmission guarantee for precise control of industrial production processes. This module, with its compact modular design, powerful anti-interference ability, and flexible compatibility, can seamlessly adapt to complex industrial scenarios such as power, petrochemicals, and metallurgy, effectively solving the pain points of traditional system modules in signal transmission stability, multi device compatibility, and other aspects. It is a key equipment for building efficient industrial control networks.

Compared with communication modules in the same series, P0903NU has the core advantage of "signal isolation enhancement+multi protocol adaptation", which not only continues the industrial grade high reliability of Foxboro products, but also improves data transmission efficiency through optimized communication architecture. At present, the module is mainly supplied with spare parts in the market. Although some specific models have stopped new production, relying on a mature technical system, it can still achieve long-term stable operation through standardized operation and maintenance management. The related technical support and spare parts service network cover a wide range.

Core technical specifications

Module Core Attributes

Industrial grade communication conversion and signal isolation module, supporting multiple types of signal conversion

Integrate communication processing and signal conditioning functions to reduce the number of system components

Power supply parameters

AC version: 220V AC/240V AC, 50/60Hz (dual voltage adaptive)

Support wide range voltage input and adapt to industrial power supply standards in different regions

Signal processing range

Analog quantity: 4-20mA DC, 0-5V DC; Digital quantity: dry contact signal, TTL level signal

Compatible with mainstream industrial sensors and actuator signals, without the need for additional signal converters

Output frequency parameter

High frequency version: 3500kHz; Standard version: 100kHz (configured according to model)

The high-frequency version is suitable for high-speed data acquisition and control scenarios, such as precision machining equipment

communication interface

Main interface: RS-485 (terminal type); Expansion interface: FBM series dedicated communication interface

Support bus topology structure, a single bus can connect 16 similar modules or devices

Isolation performance

Signal isolation voltage: 2500V AC (1 minute); Power isolation: 1500V AC (1 minute)

Adopting optoelectronic isolation technology to effectively suppress common mode interference and crosstalk, and protect the core circuit

environmental parameters

Working temperature: -20 ° C~60 ° C; Storage temperature: -40 ° C~85 ° C; Relative humidity: 5%~95% (no condensation)

Suitable for most industrial environments, stable operation without the need for additional temperature control equipment

Physical specifications

Size: 160 × 120 × 80mm (length × width × height); Weight: Approximately 0.8kg

Compact design, saving installation space for control cabinets, supporting 35mm DIN rail installation

Protection level

Module body IP20, wiring terminal IP40

It needs to be installed in a closed control cabinet to prevent dust and liquid from entering and affecting the service life of the equipment

Core functional features

P0903NU achieves multi-dimensional functional advantages through hardware circuit optimization and dedicated firmware program collaboration, accurately matching the core requirements of industrial control for communication and signal processing. The specific features are as follows:

1. Double isolation design, excellent anti-interference ability

The module adopts a triple isolation architecture of "signal power communication", in which independent optoelectronic isolation chips are used between the signal channel and the power circuit, and the isolation voltage can reach 2500V AC, far exceeding the industry average level. This design can effectively suppress common electromagnetic radiation interference, common mode interference, and power fluctuation interference in industrial sites. In strong interference environments such as steel plants and workshops with dense frequency converters, it can ensure that signal transmission errors are controlled within ± 0.1%. At the same time, isolation design can also prevent overvoltage and overcurrent caused by on-site equipment failures from being transmitted to the control system, providing dual protection.

2. Flexible communication adaptation, convenient system integration

As a standard module of the FOXBORO I/A Series system, P0903NU can seamlessly integrate with the CP controller and AW operation station of the system, supporting direct configuration of communication parameters and signal processing rules through configuration software. Meanwhile, its RS-485 interface supports Modbus RTU communication protocol, enabling data exchange with third-party PLCs (such as Siemens S7-200 series, Mitsubishi FX series), touch screens, and SCADA systems. The module supports bus address setting function. A single RS-485 bus can mount 16 devices and achieve precise data transmission and reception through address coding, reducing system wiring complexity.

3. Broadband output adjustment, adapted to diverse needs

The module provides two output frequency configurations based on the application scenario. The high-frequency 3500kHz version is suitable for high-speed data acquisition scenarios (such as precision instrument detection and high-speed production line monitoring) and can achieve microsecond level signal response; The standard 100kHz version is suitable for conventional industrial control scenarios (such as pump valve control, liquid level monitoring), reducing costs while ensuring performance. Users can configure the frequency through the dip switch on the side of the module, without the need to connect to a computer to adjust parameters, making the operation convenient and efficient.

4. Improve self diagnosis mechanism and reduce operation and maintenance costs

Built in all-round self diagnostic function, it can monitor the power status, communication link integrity, signal input range, and internal circuit temperature in real time, and provide feedback on the operating status through the red and green indicator lights on the panel: a constant green light indicates normal operation, a flashing green light indicates communication data transmission, a constant red light indicates module failure, and a flashing red light indicates signal out of range. Operation and maintenance personnel can quickly determine the type of fault by the status of the indicator lights, and with the diagnostic software of the FOXBORO I/A Series system, they can also view detailed fault logs to locate faults without disassembling modules, greatly reducing downtime for maintenance.

5. Wide voltage power supply design, strong environmental adaptability

The module adopts a wide range AC power supply design, supporting dual voltage adaptation of 220V AC and 240V AC, and can adapt to industrial power supply standards in different regions without manual switching. The power input circuit is equipped with overvoltage protection (triggered by 280V AC) and overcurrent protection (triggered by 5A) devices. When the power supply system experiences voltage fluctuations or instantaneous shocks, the power circuit can be quickly cut off to protect the internal circuit of the module from damage. This design enables the module to operate stably in remote industrial scenarios with unstable power grids.

Typical application areas

P0903NU, with its stable communication performance, strong anti-interference ability, and compact structural design, has been widely applied in multiple industrial fields, becoming the core hub for connecting field devices and control systems. The specific application scenarios are as follows:

1. Power industry: Substation and distribution system monitoring

In the substation automation system, P0903NU is mainly used to collect temperature, current, and voltage signals of high-voltage switchgear, and transmit the data to the main control PLC through RS-485 bus to achieve real-time monitoring of the operating status of distribution equipment. Its wide temperature range (-20 ° C~60 ° C) can adapt to the harsh environment of outdoor substations, and the isolation design can effectively resist electromagnetic interference generated by high-voltage equipment, ensuring the accuracy of data transmission. In the power distribution system, modules can also be used to control the signal switching of circuits and achieve remote opening and closing operations.

2. Petrochemical industry: Reactor and pipeline monitoring system

P0903NU is widely used in refineries and chemical parks for the collection and transmission of temperature and pressure signals in reaction vessels. It can be installed and used in hazardous areas (Zone 1, Zone 2) in conjunction with explosion-proof enclosures. The module converts the 4-20mA analog signal from the on-site sensor into a digital signal and transmits it to the central control system through a dedicated communication link, providing data support for precise control of the reaction process. Its anti-interference ability can ensure that signal transmission errors are controlled within the allowable range in workshops with dense large motors and compressors.

3. Metallurgical industry: Process control of steel production

In the process of blast furnace ironmaking and converter steelmaking in steel plants, modules are used to collect key parameters such as furnace temperature, cooling water flow rate, and material liquid level, and achieve closed-loop control of the production process through the FOXBORO I/A Series system. Due to the presence of a large number of frequency converters and high-voltage motors in the metallurgical workshop, electromagnetic interference is severe. The triple isolation design of P0903NU can effectively filter out interference signals, ensuring that the acquisition error of key parameters such as furnace temperature is ≤ ± 0.1%, providing a guarantee for the quality control of steel products.

4. Water treatment industry: water quality monitoring and pump valve control

In water treatment plants and sewage treatment plants, P0903NU is used to connect water quality sensors (such as pH sensors and turbidity sensors) with the control system, transmit water quality parameters in real time to the SCADA system, and receive control instructions to drive actuators such as dosing pumps and regulating valves. Its compact structural design can save control cabinet space, and the ability to connect multiple devices reduces system integration costs, making it particularly suitable for automation upgrade and renovation projects in small and medium-sized water treatment plants.

Installation and operation specifications

The installation and operation quality of P0903NU directly affects its operational stability and service life. The following specifications must be strictly followed to avoid equipment failure or safety accidents caused by improper human operation:

1. Installation environment requirements

-The installation location should be in a well ventilated control cabinet, avoiding direct sunlight, rainwater erosion, and corrosive gases (such as chlorine and hydrogen sulfide) erosion. The indoor corrosive gas content should meet the requirements of H2S<0.1ppm and Cl2<0.05ppm.

-The temperature inside the control cabinet should be maintained at -20 ° C~60 ° C, with a relative humidity of 5%~95% (no condensation). When the ambient temperature exceeds 45 ° C, a cooling fan should be equipped for forced ventilation to ensure that the surface temperature of the module does not exceed 65 ° C.

-The module should be kept away from strong electromagnetic interference sources such as high-voltage cables, frequency converters, and high-power contactors. The installation distance should be ≥ 0.5m. If the distance requirement cannot be met, a metal shielding cover should be installed around the module.

2. Installation steps

1. Cabinet preparation: Ensure that the grounding resistance of the control cabinet is less than 4 Ω, the installation rail complies with the IEC 60715 standard (35mm DIN rail), and the rail flatness error is ≤ 1mm/m to avoid uneven module stress caused by uneven installation surfaces.

2. Module fixation: Align the module buckle with the guide rail and gently push it in until you hear a "click" sound. Use your hand to gently pull the module to confirm that it is firmly fixed. The installation distance between modules should be ≥ 10mm to ensure good heat dissipation and avoid temperature rise caused by dense installation.

3. Wiring operation: Connect the power, signal, and communication cables according to the module terminal diagram. The power cord should use copper core wire with an area of 1.5mm ² or more, and the signal cable is recommended to use shielded twisted pair wire. The shielding layer should be grounded at one end (grounding resistance<1 Ω). When wiring, it is necessary to distinguish between input and output terminals, and it is strictly prohibited to connect the power supply to the signal terminal incorrectly to avoid module burnout.

4. Parameter configuration: Set the communication address (1-16) and output frequency (100kHz/350kHz) through the dip switch on the side of the module. After adjusting the dip switch, the module needs to be restarted to take effect. If you need to connect to the FOXBORO I/A Series system, you need to complete module configuration at the engineer station.

5. Pre power on inspection: Use a multimeter to measure the power supply voltage and confirm that it is within the range of 220V AC ± 10%. Check for short circuits and virtual connections in the wiring, and ensure that the communication bus terminal resistance (120 Ω) is installed properly.

3. Key points of communication configuration

-RS-485 bus configuration: The bus adopts a hand-in-hand topology structure to avoid star shaped connections. The bus length is ≤ 1200m, and RS-485 repeaters need to be used for expansion if it exceeds this limit. 120 Ω terminal resistors need to be installed at both ends of the bus to reduce signal reflection interference.

-Modbus RTU parameter settings: Configure module communication parameters in third-party systems, with baud rates supporting 9600bps and 19200bps (default 9600bps), 8-bit data bits, optional parity bits of none/odd/even (default no parity), and a stop bit of 1 to ensure consistency with module parameters.

-FOXBORO system adaptation: Add a module to the SMDH environment of the I/A Series system, select the "P0903NU" model, configure the PIO bus address and signal processing rules, and after completing the configuration, execute the "DOWNLOAD" operation to activate the module.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-