P0916PH and P0916JS are both key components of the FOXBORO I/A series distributed control system (DCS). Although they belong to the category of I/O modules, there are clear differences in their functional focus and application scenarios, forming complementary adaptations:

-P0916PH: Positioned as a high-density HART intelligent I/O module, its core function is to connect HART intelligent devices, achieve high-precision acquisition and processing of process data, and support HART protocol communication. It has rich device diagnostic capabilities and is suitable for precision control scenarios that require intelligent signal interaction.

FOXBORO P0916PH P0916JS Input/Output Module

Product series positioning and core differences

P0916PH and P0916JS are both key components of the FOXBORO I/A series distributed control system (DCS). Although they belong to the category of I/O modules, there are clear differences in their functional focus and application scenarios, forming complementary adaptations:

-P0916PH: Positioned as a high-density HART intelligent I/O module, its core function is to connect HART intelligent devices, achieve high-precision acquisition and processing of process data, and support HART protocol communication. It has rich device diagnostic capabilities and is suitable for precision control scenarios that require intelligent signal interaction.

-P0916JS: Belongs to the Compression Terminal Module (CTA), classified as a signal connection and conversion unit, mainly responsible for the secure connection task between field devices and I/A series baseboards, supporting bidirectional transmission of analog and digital signals, focusing on the stability and convenience of signal paths.

Core technical parameters

2.1 General Basic Parameters

parameter category

P0916PH

P0916JS

remark

working power supply

24V DC

24V DC

All support industrial standard DC power supply and are compatible with most DCS power supply systems

Protection level

IP67

IP66/IP67

Can resist dust and water immersion, adapt to humid and dusty industrial sites

Working temperature range

-40 ° C to+85 ° C

-40 ° C to+70 ° C

Covering extreme cold and high temperature conditions, suitable for outdoor and high-temperature workshops

relative humidity

5%~95% (non condensing)

0%~95% (non condensing)

Can work stably in high humidity environments such as chemical reaction kettle areas and water treatment workshops

2.2 Function specific parameters

-P0916PH core parameters: As a dedicated module for HART, its parameter design focuses on intelligent signal processing. Supports 16 HART channels, with input types covering various signals such as voltage and current, and outputs as standard 4-20mA DC control signals; The default measurement accuracy is ± 0.5%, which can be upgraded to higher levels through configuration; The output voltage range is 0-10VDC, which meets the control requirements of different actuators. In addition, the module is compatible with standard rack installation for easy system integration.

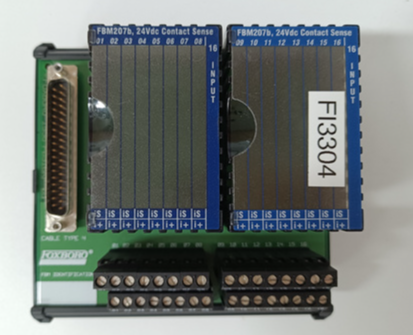

-P0916JS Core Parameters: With signal connection as the core, equipped with 16 input channels, supporting NPN and PNP input types, compatible with various field devices such as buttons, limit switches, proximity sensors, etc; The terminal block type is FBM207b, which adopts a screw free direct insertion design. The terminal supports a dual stack layout to improve connection density; The maximum output current is 2A, the rated output power is 48W, and it can drive small actuators. The module size is compact, with a typical specification of 100x60x25mm (some models have slight differences), and weighs only 0.25kg, saving cabinet space.

Core functions and product features

Both modules continue the core advantages of FOXBORO products' high reliability and ease of maintenance, while forming exclusive functional highlights based on their own positioning:

3.1 Common functional characteristics

1. Modular and hot swappable design: Adopting a standardized module structure, P0916PH can be directly installed on standard racks, P0916JS is compatible with FOXBORO 200 series baseboards, both of which support hot swappable operations and can complete module replacement without stopping the machine, greatly reducing maintenance time.

2. Strong anti-interference ability: Through circuit optimization design, it can resist electromagnetic interference, voltage fluctuations and other interference sources in industrial sites, ensuring the stability of signal transmission, and is suitable for strong interference environments such as oil refining and metallurgy.

3. International standard compliance: The product has passed multiple international industrial standard certifications, and its protection level and environmental adaptability comply with relevant IEC specifications. It can be applied in industrial scenarios in different regions around the world.

3.2 Highlights of Personalized Features

-P0916PH: Intelligent HART Interaction Capability: As a dedicated module for HART, its core advantage lies in supporting bidirectional communication of the HART protocol. It can not only collect measurement data from on-site devices, but also read device status and diagnose fault information (such as sensor drift and line short circuit), achieving "predictive maintenance"; At the same time, the parameters of on-site devices can be configured through the HART protocol to enhance the flexibility of system control.

-P0916JS: Efficient signal connection capability: adopting clear terminal color coding design, combined with screw free direct insertion termination technology, can quickly complete wire connection and identification, reducing wiring error rate; The dual stack terminal design enables a single module to achieve 32 connection points, increasing system connection density in a limited space; Redundant design further reduces the risk of signal transmission failures and ensures the continuous operation of the system.

Application scenarios and industry adaptation

Based on the differences in functional positioning, P0916PH and P0916JS form a "collaborative and complementary" application mode in industrial scenarios, jointly supporting the stable operation of DCS systems:

4.1 P0916PH Typical Applications

Focusing on "intelligent data acquisition and precision control", mainly applied in scenarios that require HART smart device access:

-Oil and gas industry: Connect HART pressure transmitters and temperature sensors to collect pressure and temperature data of oil and gas pipelines, and provide feedback on equipment status through the HART protocol to ensure safe and controllable extraction and transportation processes.

-Chemical industry: By linking with HART level gauges and flow sensors, high-precision collection and control of reaction kettle level and material flow can be achieved. At the same time, equipment diagnostic functions can be used to warn of faults in advance and avoid production interruptions.

-Power industry: used for parameter monitoring of generator sets, connecting HART vibration sensors and temperature sensors, collecting equipment operation data, and providing data support for unit operation and maintenance.

4.2 P0916JS Typical Applications

Focusing on "signal pathway construction and device connection", it is widely used in various scenarios that require stable signal transmission:

-Manufacturing industry: Connect proximity switches and photoelectric sensors to the production line, transmit equipment operation status signals to PLC, and achieve process control and fault alarm for automated production.

-Water treatment industry: As a bridge connecting water quality monitoring equipment and DCS systems, it transmits signals from pH and turbidity sensors to support the automation control of sewage treatment processes.

-Food and beverage industry: Connect temperature and pressure sensors on the production line, ensure parameter compliance in the food processing process through stable signal transmission, and comply with food safety standards.

Selection and operation suggestions

5.1 Core Basis for Selection

-If the system needs to be connected to a HART smart device to achieve bidirectional interaction between data acquisition and device diagnosis, P0916PH is preferred;

-If the requirement is to build a stable signal path between on-site equipment and DCS baseboard, with a focus on connection efficiency and density, P0916JS is preferred;

-It is recommended to prioritize P0916PH for extreme high temperature scenarios (such as heating furnace areas in steel metallurgy), as its maximum operating temperature of 85 ° C is more advantageous.

5.2 Key points of operation and maintenance

1. During module installation, it is necessary to ensure that the wiring terminals are securely fastened. For P0916JS's direct insertion terminals, it is necessary to confirm that the wires are fully inserted to avoid poor contact;

2. Regularly check the module status of P0916PH through the HART communication tool and promptly clear any fault alarms;

3. When replacing modules, it is necessary to use original products of the same model to ensure compatibility with the I/A series DCS system. Original modules can provide 12 months of quality assurance.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-