FOXBORO PP0926KN is a high-performance field input/output control module, belonging to the core supporting component series of FOXBORO I/A Series distributed control system (DCS). Its core positioning is as a key connection unit between field equipment and control system, responsible for collecting and processing various sensor signals on site, as well as precise output and execution of control system control instructions. This module has multi-channel signal processing capabilities, supports adaptation to multiple signal types, and can be widely integrated into various industrial automation control systems, providing reliable guarantees for process parameter monitoring and equipment control. The product complies with relevant standards in the field of industrial control and is suitable for various harsh industrial scenarios such as power, chemical, oil and gas.

FOXBORO PP0926KN control module

Brand background and product positioning

FOXBORO, as a core industrial control brand under Schneider Electric, has built a deep technical barrier and market reputation in key industrial fields such as energy, chemical, and power worldwide with a century long accumulation of process automation technology. The I/A Series system and supporting module products launched by it have the core advantages of high reliability, strong anti-interference ability, and flexible system adaptability, providing stable on-site data acquisition and execution control support for industrial automation control systems.

FOXBORO PP0926KN is a high-performance field input/output control module, belonging to the core supporting component series of FOXBORO I/A Series distributed control system (DCS). Its core positioning is as a key connection unit between field equipment and control system, responsible for collecting and processing various sensor signals on site, as well as precise output and execution of control system control instructions. This module has multi-channel signal processing capabilities, supports adaptation to multiple signal types, and can be widely integrated into various industrial automation control systems, providing reliable guarantees for process parameter monitoring and equipment control. The product complies with relevant standards in the field of industrial control and is suitable for various harsh industrial scenarios such as power, chemical, oil and gas.

Key technical parameters

1. Core channel parameters

-Input channels: 10 standard input channels, supporting various signal types such as analog and digital signals

-Output channels: 10 standard output channels, capable of driving various industrial actuators

-Signal processing: Integrated Sigma Delta data conversion technology, scanning channel signals every 25 milliseconds

-Filtering function: configurable moving average filter, effectively suppressing process noise and power interference

2. Communication interface parameters

-Communication protocol: Supports mainstream industrial protocols such as Modbus and Ethernet

-Bus interface: compatible with FOXBORO I/A Series system 2Mbps fieldbus, supporting redundant configuration

-Communication speed: The fieldbus communication component (FCM) can achieve conversion and adaptation to the 10Mbps rate of Ethernet fieldbus

-Redundancy feature: Supports redundant Ethernet fieldbus connections, can automatically switch communication paths (A/B paths), ensuring communication continuity

3. Power supply and power consumption parameters

-Power supply method: Obtain independent DC power supply through DIN rail mounted substrate

-Power consumption: Low power design, typical power consumption ≤ 10W (subject to actual configuration)

4. Environmental and physical parameters

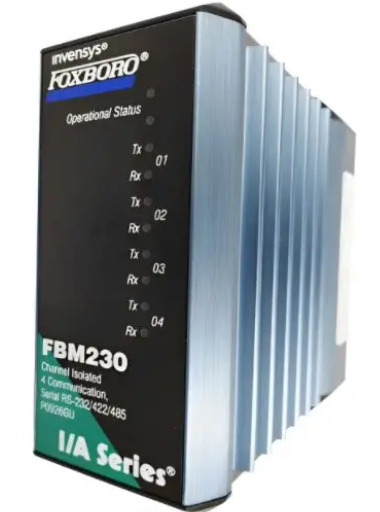

-Shell material: pressed aluminum shell, with excellent physical protection and heat dissipation performance

-Installation method: DIN rail mounted substrate installation, supporting cabinet rack mounting

-Working temperature: -20 ° C~60 ° C, suitable for harsh industrial temperature environments

-Relative humidity: 5%~95% (no condensation)

-Protection level: Complies with ISA S71.04 standard for protection against harsh environments

-Vibration adaptability: can withstand 5-150Hz sine vibration, acceleration ≤ 2g

-Impact adaptability: can withstand a peak impact of 30g (lasting for 11ms)

5. Fault safety parameters

-Fault configuration: supports fault safe hold/return mode, and can set fault return data based on each channel

-Status indication: Panel LED indicator light, displaying module operation status, communication status, and channel fault status

Typical application areas and scenarios

The FOXBORO PP0926KN control module, with its multi-channel processing, strong anti-interference ability, flexible communication adaptability, and reliable fault safety design, is widely used in various industrial automation control scenarios, especially in key industrial fields with high requirements for system stability and safety, including:

1. Power industry

In the DCS monitoring system of power plants, it is used to collect key parameters such as boiler temperature, pressure, water level, turbine speed, vibration, generator output voltage, current, etc. At the same time, it outputs control signals to drive equipment such as feed pumps, blowers, regulating valves, etc., to ensure the stable operation and efficient power generation of the generator set. Its redundant communication and fault safety functions can effectively avoid power generation interruptions caused by equipment failures and improve the reliability of power production.

2. Oil and gas industry

Suitable for scenarios such as oil and gas extraction platforms, oil and gas pipelines, and refineries, it is used to collect parameters such as oil and gas well pressure, flow rate, pipeline leakage status, refining reactor temperature, pressure, etc., and control the operation of wellhead valves, pipeline shut-off valves, heating furnaces, and other equipment. The industrial grade protection design of the module can adapt to harsh outdoor environments, and its anti-interference ability can resist the interference of strong electromagnetic equipment on site, ensuring the safety and stability of oil and gas production and transportation processes.

3. Chemical industry

In the DCS distributed control system of chemical production workshops, it is used to achieve real-time collection of parameters such as temperature, pressure, liquid level, and raw material concentration in the chemical reaction process, as well as precise control of equipment such as mixing motors, feed pumps, and discharge valves. Its multi-channel parallel processing capability can meet the diverse parameter monitoring requirements of complex chemical processes, and the fault safety configuration function can effectively avoid safety accidents caused by reaction loss of control.

4. Paper and textile printing and dyeing industry

In paper production lines, printing and dyeing machines, and other equipment, it is used to collect parameters such as temperature, humidity, tension, and liquid level during the production process, and control the operation of drying equipment, transmission motors, regulating valves, and other devices. The high stability and anti-interference ability of the module can adapt to the environmental conditions of high dust and high humidity in the workshop, ensuring the stability of production process parameters and improving product quality.

5. Water treatment and environmental protection industry

In the intelligent water supply control system and water quality monitoring system of sewage treatment plants, it is used to collect water quality parameters such as pH value, dissolved oxygen, turbidity, etc., and control the operation of sewage lifting pumps, aeration equipment, dosing devices and other equipment. By communicating and interconnecting with the upper computer system, centralized monitoring and automated adjustment of the water treatment process can be achieved, improving water treatment efficiency and environmental compliance rate.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-