ABB PPC905AE101 (order number: 3BHE014070R0101) is a high-performance integrated control module designed for industrial process control and equipment drive scenarios. It is a core component of ABB AC 800PEC series process control units. This module is positioned with "precise control+efficient drive" as its core, integrating multiple functions such as logic control, process regulation, signal processing, and drive interfaces. It can directly interface with sensors, actuators, and high-power drive units to achieve closed-loop control and equipment linkage management of complex industrial processes. It is widely used in industries such as power, chemical, metallurgy, and papermaking that require strict real-time and reliability control.

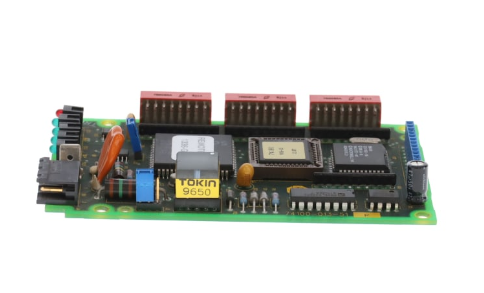

ABB PPC905AE101 3BHE014070R0101 control module

Product Overview

ABB PPC905AE101 (order number: 3BHE014070R0101) is a high-performance integrated control module designed for industrial process control and equipment drive scenarios. It is a core component of ABB AC 800PEC series process control units. This module is positioned with "precise control+efficient drive" as its core, integrating multiple functions such as logic control, process regulation, signal processing, and drive interfaces. It can directly interface with sensors, actuators, and high-power drive units to achieve closed-loop control and equipment linkage management of complex industrial processes. It is widely used in industries such as power, chemical, metallurgy, and papermaking that require strict real-time and reliability control.

It integrates ABB's core algorithms and hardware design technology in the field of industrial control, adopts a multi-core processor architecture and modular interface design, and has the characteristics of fast computing speed, high control accuracy, wide interface compatibility, and strong anti-interference ability. It can be used as an independent control unit to meet the needs of small control scenarios, and can also be connected to distributed control systems (DCS) as expansion nodes. It is a key hardware carrier for building flexible and efficient industrial control systems.

Core functions and control features

1. Core control functions

-Multi mode precise control: supports three core modes of logic control, continuous process control, and motion control, with built-in advanced algorithms such as PID, fuzzy PID, cascade control, feedforward control, etc. The response time of logic control is ≤ 1ms, and the process control adjustment accuracy reaches ± 0.1%, which can meet the diverse control needs from discrete manufacturing to continuous processes.

-High speed signal acquisition and processing: integrates 16 high-precision analog input (AI), 12 analog output (AO), 32 digital input (DI), and 24 digital output (DO) interfaces. The AI channel uses a 16 bit A/D conversion chip with a sampling rate of 1kHz, which can accurately capture small changes in process parameters such as temperature, pressure, and flow rate, providing reliable data support for control decisions.

-Drive collaboration and device linkage: Equipped with a dedicated pulse output interface (maximum frequency of 1MHz) and PWM drive signal output function, it can directly drive servo motors, stepper motors, frequency converters and other actuators, supporting multi axis linkage control; At the same time, internal logic programming is used to achieve linkage start stop and status feedback with devices such as valves, pumps, and fans, improving system collaboration efficiency.

-Fault diagnosis and fault-tolerant control: Built in comprehensive self diagnostic mechanism, which can monitor key links such as module power supply, CPU operation, I/O interface status, and communication links in real time. When a fault is detected, it will immediately trigger local alarms and remote notifications, and record fault codes and related parameters; Support dual machine hot standby configuration, with a switching time between primary and backup modules of ≤ 5ms, ensuring uninterrupted control process.

2. Additional practical features

-Rich communication and expansion capabilities: Supports mainstream industrial communication protocols such as PROFINET, EtherCAT, Modbus TCP/RTU, Profibus DP, etc., equipped with 2 Gigabit Ethernet interfaces, 1 RS485 interface, and 1 CANopen interface, which can seamlessly connect to DCS, PLC, upper monitoring systems, and intelligent instruments, achieving data interconnection between the control layer and information layer; Simultaneously supporting the increase of I/O points and special function interfaces through expansion modules.

-Flexible programming and configuration: compatible with ABB Control Builder M and IEC 61131-3 standard programming environment, supporting multiple programming methods such as Function Block Diagram (FBD), Structured Text (ST), Ladder Diagram (LD), etc., providing rich industry-specific function libraries (such as boiler control and fan control libraries); Equipped with a 7-inch color touch screen, it supports on-site parameter configuration, status monitoring, and troubleshooting, reducing debugging difficulty.

-Data storage and traceability: Equipped with 8GB industrial grade flash memory and 2GB DDR4 memory, it can store massive control programs, historical operating data, fault logs, and process parameters. The sampling interval of historical data can be flexibly configured within the range of 10ms-1h, supporting local data export and remote upload, providing a data foundation for production process traceability, process optimization, and fault analysis.

-Strong environmental adaptability and reliability: using industrial grade high weather resistant components, passing IEC 61000-6-2/3 electromagnetic compatibility testing, can effectively resist electromagnetic radiation, voltage surges, and dust interference in industrial sites; The working temperature range is -25 ℃~+70 ℃, with a protection level of IP20 (module body), and can adapt to various installation environments such as control rooms, control cabinets, and on-site terminal boxes.

Key technical parameters

parameter category

Specifications

Instructions

Core processor

Dual core industrial grade processor with a clock frequency of ≥ 800MHz

Multi core parallel processing ensures efficient operation of complex control algorithms

power supply parameters

Input voltage: DC 24V ± 20%; Power consumption: ≤ 30W; equipped with anti reverse protection function

Adapt to commonly used industrial DC power sources, ensuring safe and reliable power supply

Analog interface

AI: 16 channels, 4-20mA DC/0-10V DC (configurable), 16 bit accuracy; AO: 12 channels, 4-20mA DC, 14 bit accuracy

High precision signal acquisition and output to meet process control requirements

Digital quantity interface

DI: 32 channels, optional PNP/NPN, response time ≤ 10 μ s; DO: 24 channels, relay output (AC 250V/5A)

Capture digital signals at high speed to drive various industrial equipment

Driver interface

4-channel pulse output (up to 1MHz); 8 PWM outputs (duty cycle adjustable from 0-100%)

Directly drive actuators such as motors and frequency converters

communication interface

2-channel Gigabit Ethernet (supporting PROFINET/EtherCAT); 1 RS485 (Modbus RTU) channel; 1 CANopen channel

Multi protocol compatibility enables seamless integration with various systems

storage capacity

Program storage: 8GB flash memory; Data storage: 2GB DDR4 memory (expandable up to 4GB)

Meet the needs of massive data storage and program operation

control performance

Logic control cycle: ≤ 1ms; PID regulation cycle: ≤ 10ms; Multi axis linkage accuracy: ± 0.01mm (in conjunction with servo system)

High real-time performance and control accuracy ensure stable industrial processes

environmental parameters

Working temperature: -25 ℃~+70 ℃; Humidity: 5%~95% (no condensation); Protection level: IP20

To adapt to complex industrial environments, it needs to be installed inside the control cabinet

Installation method

35mm standard DIN rail installation or panel embedded installation

Meets industrial standardization installation requirements and facilitates system integration

Typical application scenarios

This control module, with its multi-mode control capability, rich interface configuration, and high reliability, can play a core role in various complex industrial scenarios. Typical applications include:

1. Auxiliary equipment control in the power industry: used for controlling boiler feed pumps, induced draft fans, and forced draft fans in thermal power plants. By collecting parameters such as pressure, flow rate, and temperature, the cascade PID algorithm is used to adjust the motor speed and valve opening, achieving boiler combustion efficiency optimization and water level stability control; At the same time, it is connected to the DCS system of the power plant and receives centralized dispatching instructions.

2. Chemical process control: In the control of chemical reaction vessels, distillation towers and other equipment, closed-loop control of key parameters such as reaction temperature, pressure, liquid level, and component concentration is achieved. Through logic programming, automatic linkage of feeding, reaction, discharge and other processes is realized to ensure stable quality of chemical products and avoid safety risks such as overheating and overpressure.

3. Equipment control in the metallurgical industry: used for roll pressure control and steel strip tension control in steel rolling production lines, as well as temperature and current control in electrolytic cells during non-ferrous metal smelting. Through high-speed signal processing and multi axis linkage control, it improves rolling accuracy and smelting efficiency, and reduces product scrap rates.

4. Paper and textile industry: precise control of process parameters in the net dewatering control, pressing pressure regulation, and drying temperature control of paper machines to ensure uniform paper thickness and moisture content standards; To achieve stability and consistency in fabric weaving through yarn tension control and weaving speed adjustment in textile machines.

5. Municipal and Environmental Engineering: Used for dissolved oxygen control in aeration tanks and speed regulation of sludge return pumps in sewage treatment plants. By collecting water quality sensor signals, the operating status of aeration fans and pumps can be dynamically adjusted to improve sewage treatment efficiency; In the waste incineration power generation project, controlling the temperature of the incinerator and the speed of the grate ensures that the incineration efficiency meets environmental standards.

6. Intelligent manufacturing production line: In automotive parts assembly lines and electronic component packaging production lines, it serves as an on-site control unit to achieve functions such as robot grasping, conveyor belt conveying, and linkage of detection equipment. Through high-speed I/O interfaces and motion control functions, it improves the automation level and production pace of the production line.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-