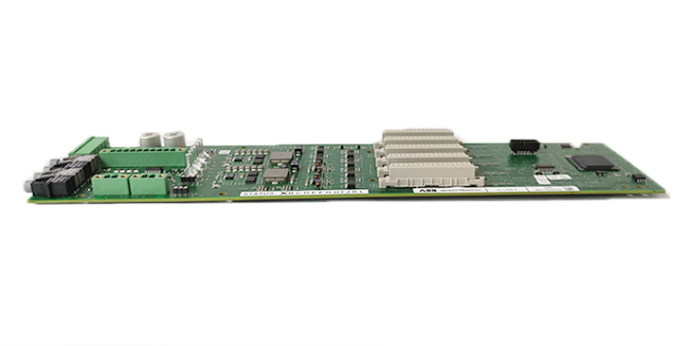

ABB SNAT602 TAC TAC Interface Board is a specialized interface board designed for collaborative interconnection scenarios between industrial control systems. It belongs to the ABB Advant OCS or Symphony Plus control system supporting product line and is positioned as a "bridge for multi system signal interaction and protocol conversion". This interface board focuses on solving the signal compatibility and data exchange problems between different control subsystems (such as TAC building automation system and industrial DCS system) and devices. It integrates multi protocol conversion, signal isolation, and data preprocessing functions, adopts a high stability hardware architecture and anti-interference design, and can achieve bidirectional conversion between TAC protocol and industrial standard protocol in scenarios such as building intelligent control, industrial park comprehensive monitoring, and large-scale public facility automation. It provides reliable interface support for cross system collaborative control (such as building energy management and industrial production energy scheduling linkage), especially suitable for comprehensive automation projects that require multi system integration.

ABB UCD224A102 Control Module

Product core positioning

ABB UCD224A102 is a high-performance industrial control module that combines general control and specialized regulation capabilities. It is not only the core control unit of distributed control systems (DCS), but also a key component for specialized applications such as voltage regulation and excitation control. Its design focuses on "high precision+high reliability", meeting the stringent automation requirements of multiple industries through robust components and wide environmental adaptability, and is widely labeled as the benchmark product of ABB UCD series.

Key technical parameters

Power supply specifications

24VDC

24VDC, Power consumption 9W

Supplementary power consumption data for special scenarios

Environmental adaptability

Working temperature -40 ℃~+85 ℃, IP67

Working temperature -25 ℃~+60 ℃, IP20

It is speculated that there are differences in different protection versions

Channel configuration

16 channels for input/output each

32 channel 24V scanning input (Abstract 6)

The number of channels varies with the application scenario

Communication capability

Profibus, Modbus, Ethernet/IP

Added EtherCAT and 2 RS232 interfaces

High end model extension protocol support

Core hardware

32-bit RISC CPU, 8MB Flash+16MB RAM

Disclosure of processor details for specialized models

Physical specifications

150×100×50mm,1.5kg

263×138×88mm,2.35kg

Size and weight vary with functional integration

Core functions and competitive advantages

1. Multidimensional control capability

General control: supports 16 input/output signal processing, can connect temperature, pressure and other sensors with valves, motors and other actuators to achieve closed-loop control of the production line;

Special regulation: With precise control of DC current (± 0.1% accuracy), voltage regulation, and excitation system management functions, it can directly drive motors or stabilize generator magnetic fields;

Algorithm support: Built in advanced control algorithms, compatible with programming languages such as ladder diagrams and structured text, suitable for complex logic development.

2. Strong environmental adaptability

Extreme temperature tolerance: The mainstream version can operate stably from -40 ℃ (in cold regions) to+85 ℃ (in high-temperature workshops), far exceeding the industrial standard (-20 ℃~+60 ℃);

High protection level: IP67 version achieves dust and water resistance, and can be directly installed next to damp and dusty on-site equipment without the need for additional protective boxes.

3. Flexible system integration

Multi protocol compatibility: covering Profibus (device level communication), Modbus (universal protocol), Ethernet/IP (Ethernet communication), and can be connected to mainstream DCS systems such as ABB AC800M;

Convenient installation: Supports DIN rail or PCB board fixation, suitable for installation needs of distributed cabinets and compact devices.

Typical application scenarios

1. Core application areas

Energy and Electricity

Generator excitation control, grid voltage regulation

High precision signal processing, high reliability

Manufacturing industry

Production line automation, robot motion control

Multi channel input/output, fast response

Petrochemical industry

Temperature and pressure control of reaction kettle, regulation of pipeline valves

Extreme environmental tolerance, IP67 protection

Transportation and Communications

Rail transit signal control, charging pile power management

Wide temperature operation, protocol compatibility

2. Example of System Roles

In the DCS system of a large refinery, UCD224A102 plays a dual role: as an analog input module, it collects 16 temperature sensor signals and uploads them to the central controller through Modbus protocol; At the same time, as the execution control unit, adjust the opening of 8 valves based on feedback signals to control the reaction rate.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-