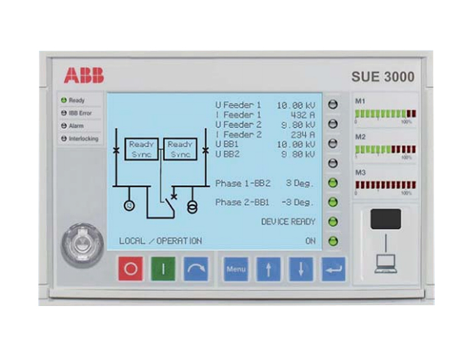

ABB SUE3000 (order number: 1VCR007346 G0028) is a professional high-speed transmission equipment designed for industrial high bandwidth data transmission scenarios, belonging to ABB's industrial communication and data transmission solution system. This device has the core advantages of ultra high speed data transmission capability, low latency response characteristics, and industrial grade stability performance. It is specifically designed to solve the problem of rapid transmission of large amounts of real-time data, high-definition video streams, and control instructions in industrial automation systems. It is widely used in fields such as smart factories, rail transit communication signal systems, power dispatch centers, and large industrial production lines that require extremely high data transmission speed and reliability.

ABB SUE3000 1VCR007346 G0028 High speed Transmission Equipment

Equipment Overview

ABB SUE3000 (order number: 1VCR007346 G0028) is a professional high-speed transmission equipment designed for industrial high bandwidth data transmission scenarios, belonging to ABB's industrial communication and data transmission solution system. This device has the core advantages of ultra high speed data transmission capability, low latency response characteristics, and industrial grade stability performance. It is specifically designed to solve the problem of rapid transmission of large amounts of real-time data, high-definition video streams, and control instructions in industrial automation systems. It is widely used in fields such as smart factories, rail transit communication signal systems, power dispatch centers, and large industrial production lines that require extremely high data transmission speed and reliability.

Its core positioning is to serve as the "backbone node" of industrial grade high-speed data transmission networks, connecting dispersed control units, data acquisition equipment, monitoring terminals, and cloud management platforms to achieve non blocking and low latency transmission of massive data, providing solid transmission guarantees for real-time monitoring, intelligent decision-making, and remote operation and maintenance of industrial production. It is one of the key communication devices to promote industrial digital transformation.

Key technical parameters

Basic Information

Model/Order Number

SUE3000 / 1VCR007346 G0028

transmission parameters

Port type and quantity

4 x Gigabit Ethernet electrical ports (RJ45), 2 x Gigabit Ethernet optical ports (SFP slots), 1 x industrial dedicated high-speed interface

Single port transmission rate

10/100/1000Mbps (adaptive)

transmission delay

When the data frame length is 1500 bytes, the delay is ≤ 1ms; the delay of key control frames is ≤ 500 μ s

Support transmission media

Category 5e/6 Ethernet cables (transmission distance ≤ 100m), single-mode fiber optic cables (transmission distance ≤ 20km), multi-mode fiber optic cables (transmission distance ≤ 550m)

Power parameters

power supply voltage

DC 24V ± 15% or AC 110/220V ± 10% (dual power redundant input)

power consumption

Typical value ≤ 15W, maximum not exceeding 20W

environmental parameters

Operating Temperature

-40℃ - +70℃

Storage temperature

-40℃ - +85℃

relative humidity

5% -95% (no condensation), supports operation in humid environments

Mechanical and protective parameters

Installation method

DIN rail installation (35mm standard rail) or panel installation

Protection level

IP30 (rail installation), IP40 (panel installation with protective cover)

network management

management style

Support web management, SNPv3, ABB Network Manager management platform

Typical application scenarios

4.1 Intelligent Factory Data Transmission Network

In smart factories, the SUE3000 equipment serves as a high-speed transmission hub between the production workshop and the control center, connecting industrial robots, intelligent sensors, machine vision equipment, and production execution systems (MES) within the workshop. Long distance high-speed data transmission between the workshop and the control center is achieved through a gigabit optical port, which uploads real-time robot operation status, product quality inspection data, production progress information, etc. to the control center. At the same time, the production scheduling instructions from the control center are quickly issued to various equipment, supporting the flexible production and intelligent scheduling of the factory, and improving production efficiency and product quality control level.

4.2 Rail Transit Signal and Monitoring System

In the fields of subway, light rail and other rail transit, this equipment is used to build high-speed transmission networks for signal systems and monitoring systems. On the one hand, the low latency transmission characteristics ensure real-time interaction of key signals such as train position and speed in the Automatic Train Control (ATC) system, ensuring safe train operation and efficient scheduling; On the other hand, connecting high-definition surveillance cameras and environmental sensors along the line enables concurrent transmission of multiple high-definition video streams and environmental data, providing comprehensive on-site visualization information for the operation and dispatch center, supporting emergency response and daily operation management.

4.3 Power System Dispatching and Operation Network

In large power plants and regional power dispatch centers, the SUE3000 equipment is used to connect generator control units, substation monitoring equipment, power load monitoring terminals, and the main system of the dispatch center. Real time collection and transmission of generator operating parameters, grid load data, and equipment status information through high-speed transmission capability, providing accurate data support for load allocation and fault prediction in the dispatch center; Simultaneously supporting the transmission of remote operation and maintenance data, operation and maintenance personnel can remotely monitor the status and troubleshoot on-site equipment through the network, reducing operation and maintenance costs and operational risks.

4.4 Large scale metallurgical and chemical production lines

In the processes of steel, non-ferrous metal smelting, and large-scale chemical production, the production line has a large span, a large number of equipment, and requires real-time transmission of a large number of control instructions and monitoring data. The SUE3000 equipment can build a high-speed transmission network covering the entire production line, connecting the control system and central monitoring platform of key equipment such as heating furnaces, rolling mills, and reaction kettles, achieving real-time feedback of process parameters such as temperature, pressure, and liquid level, and accurate issuance of control instructions to ensure stable operation of the production process; Simultaneously supporting the transmission of high-definition monitoring videos for production lines, providing strong support for safety production monitoring.

Installation and usage precautions

-Before installing the equipment, it is necessary to verify that the model, order number, and design scheme are consistent. The appearance of the equipment should be checked for scratches, the interfaces should be undamaged, and accessories (such as power cables, installation brackets, SFP optical modules) should be complete and matched.

-Choose the appropriate installation position based on the installation method. When installing the guide rail, ensure that it is firmly fixed, and when installing the panel, ensure that the installation surface is flat; At least 10cm of heat dissipation space should be reserved around the equipment to avoid stacking devices with high heat generation in close proximity and prevent poor heat dissipation from causing equipment failure.

-Before wiring operation, the power supply of the equipment must be disconnected, and wiring must be strictly carried out according to the definition of the equipment wiring terminal: the power supply wiring should distinguish between positive and negative poles and AC/DC types to avoid reverse or wrong connections; Ethernet port wiring requires the use of standard Category 5e/6 Ethernet cables, with crystal head production specifications; When connecting optical ports, it is necessary to clean the end faces of the optical module and fiber optic connector first to avoid dust pollution affecting transmission quality, and the bending radius of the fiber optic cable must be greater than the minimum bending radius requirement.

-Before powering on the equipment, it is necessary to check the wiring correctness again. After confirming that there are no errors, first connect the backup power supply, then connect the main power supply, observe the status of the power indicator light, and confirm that the power supply is normal; When configuring for the first time, it is necessary to log in to the device through the console or web interface, set basic network parameters such as device IP address, subnet mask, gateway, etc., to ensure connectivity with the management network.

-Configure transmission parameters according to the application scenario, including port rate mode (adaptive or forced gigabit), VLAN partitioning, priority queue, redundant link switching parameters, etc., to ensure the priority transmission of critical data and the normal effectiveness of network redundancy functions.

-Regularly check the status of equipment indicator lights (power lights, port chain lights, data transmission lights, fault alarm lights) during daily operation. Monitor the equipment operation status, port traffic, and transmission delay through the management platform, and promptly troubleshoot any abnormalities found; Regularly clean the dust on the surface of the equipment and check the firmness of the connection between the wiring terminals and the fiber optic connectors.

-When performing firmware upgrades or parameter modifications, it is necessary to backup the current configuration file in advance. During the upgrade process, it is forbidden to disconnect the device power to avoid upgrade failures that may cause the device to malfunction; After the upgrade is completed, the device needs to be restarted and the parameter configuration and transmission functions need to be verified to be normal.

-When used in harsh industrial environments, specialized protective cabinets should be equipped for the equipment to avoid direct impact of dust, corrosive gases, and strong electromagnetic interference on equipment operation; When the ambient temperature is below -20 ℃, insulation measures should be taken to ensure that the equipment operates within the allowable temperature range.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-