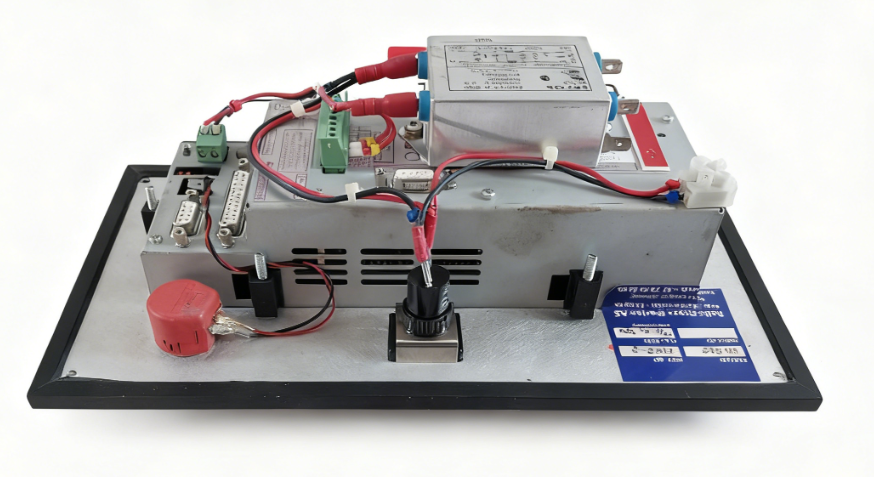

Rolls-Royce UN921 - Marine AS OPRETOR PANEL

The Rolls-Royce UN921 stands as a pinnacle of advanced automation technology, engineered specifically to meet the rigorous demands of the power industry, petrochemical sectors, and general automation applications. Renowned for its robust input/output capacity, exceptional durability, and superior performance metrics, the UN921 offers a reliable and scalable solution for complex control environments. At its core, the Rolls-Royce UN921 features a high-density I/O configuration capable of handling extensive signal integration with precision and speed. It supports up to 256 digital inputs and outputs, alongside 64 analog channels, allowing seamless interfacing with a wide variety of sensors and actuators. This expansive I/O capacity ensures that operators can manage intricate automation processes without compromising responsiveness or accuracy. The unit’s processing capabilities are bolstered by a high-speed CPU architecture, delivering real-time data processing with minimal latency, critical for fault detection and process optimization in demanding industrial settings. Built to withstand harsh environmental conditions, the UN921 incorporates a ruggedized chassis with IP65-rated sealing, providing resistance against dust, moisture, and vibration commonly encountered in petrochemical plants and power generation facilities.

Its thermal management system ensures stable operation across a broad temperature range from -40°C to +70°C, making it an ideal choice for both indoor control rooms and challenging outdoor installations. The unit’s longevity is further guaranteed by rigorous Rolls-Royce quality control standards and the use of industrial-grade components designed for continuous 24/7 operation. In practical applications, the Rolls-Royce UN921 excels in complex automation tasks such as turbine control, refinery process regulation, and energy distribution monitoring. Within the power industry, it plays a crucial role in managing grid stability and optimizing generation efficiency by providing instantaneous feedback and adaptive control strategies. In petrochemical environments, the UN921’s precise analog and digital I/O handling supports critical parameters like temperature, pressure, and flow control, ensuring safe and efficient operations. For general automation, it offers unparalleled flexibility and integration capabilities, allowing seamless communication with SCADA systems, PLCs, and other control networks. Comparatively, the UN921 distinguishes itself from other Rolls-Royce automation products such as the Rolls-Royce UN970 and UN924 by delivering enhanced I/O density and faster processing speeds, making it particularly suited for larger-scale automation projects requiring more granular control.

While the Rolls-Royce DEP.STEERING GEAR-TENFJORD focuses on niche steering applications, the UN921’s versatile architecture supports a broader range of industrial control scenarios. Additionally, models like the Rolls-Royce MEG-100-101-102 and MEF-101 provide specialized monitoring functions but do not match the UN921’s comprehensive I/O and processing capabilities, which enable it to function both as a central control unit and a data acquisition system. Alongside the Rolls-Royce UN921, complementary models such as the Rolls-Royce Icon DP_94102 and Rolls-Royce LCD1026 B extend the control interface capabilities, offering enhanced visualization and operator interaction. The Rolls-Royce 5880-PC1020 rev. B and 5880-PC1019 Rev. B modules serve as reliable peripheral expansions, allowing users to scale their automation systems effectively. For advanced power management, the Rolls-Royce PSR and RRPWR16 units integrate seamlessly with the UN921, delivering comprehensive power system regulation and protection. Moreover, the Rolls-Royce CU40-0106-50 communication units ensure robust network connectivity, vital for distributed automation frameworks.

The application of UN921 in power industry, petrochemical, and general automation settings is supported by its ability to integrate with legacy and modern systems alike, including models such as the Rolls-Royce 1403c 12 and 222-653 Plc2001b.PCB, which remain critical in many existing installations. This backward compatibility ensures a smooth transition and upgrade path, minimizing downtime and maximizing return on investment. In summary, the Rolls-Royce UN921 represents a sophisticated automation solution characterized by large-scale I/O capacity, rugged design, and high-performance processing tailored for demanding industrial environments. When combined with other Rolls-Royce automation products like the UN970, DEP.STEERING GEAR-TENFJORD, Icon DP_94102, and MEG-100-101-102, it forms an integrated ecosystem that empowers industries to achieve enhanced operational efficiency, safety, and control precision. Whether deployed in power plants, petrochemical refineries, or diverse automation applications, the UN921 delivers unmatched reliability and scalability, making it a cornerstone of advanced industrial automation solutions.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-