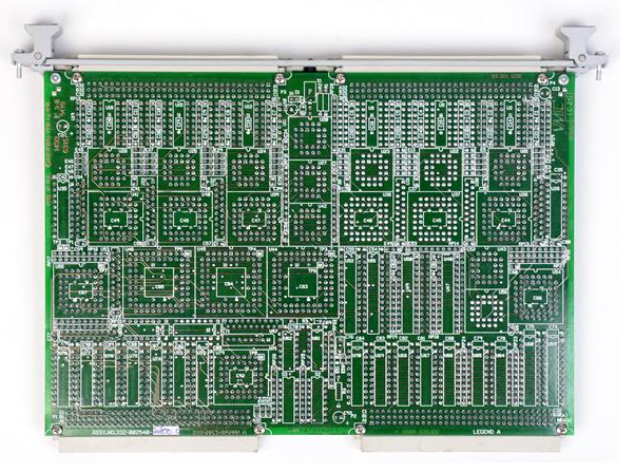

The GE VMIVME 2540-300 intelligent counter is a high-precision industrial control module developed by General Electric (GE) based on the VME bus architecture. As the "digital sensing and measurement core" in industrial automation systems, it is mainly used for precise acquisition, counting, and processing of pulse signals, frequency signals, and speed signals in industrial sites. This module integrates high-resolution counting chips and flexible programming functions, supporting multi-mode counting, threshold alarm, data caching, and other functions. It is compatible with the VME bus standard control system and has the characteristics of high reliability, strong anti-interference ability, and fast response speed. It is widely used in industrial fields such as machine processing, metallurgical rolling, textile printing and dyeing, printing and packaging, which require strict measurement and control of motion parameters.

GE VMIVME 2540-300 Intelligent Counter

Product Overview

The GE VMIVME 2540-300 intelligent counter is a high-precision industrial control module developed by General Electric (GE) based on the VME bus architecture. As the "digital sensing and measurement core" in industrial automation systems, it is mainly used for precise acquisition, counting, and processing of pulse signals, frequency signals, and speed signals in industrial sites. This module integrates high-resolution counting chips and flexible programming functions, supporting multi-mode counting, threshold alarm, data caching, and other functions. It is compatible with the VME bus standard control system and has the characteristics of high reliability, strong anti-interference ability, and fast response speed. It is widely used in industrial fields such as machine processing, metallurgical rolling, textile printing and dyeing, printing and packaging, which require strict measurement and control of motion parameters.

Core Features

1. High precision multi-mode counting capability

Adopting a 24 bit high-resolution counting chip, the counting frequency can reach up to 1MHz, supporting multiple working modes such as rising edge counting, falling edge counting, bidirectional counting (increasing and decreasing counting), frequency measurement, cycle measurement, and speed calculation. It can accurately capture high-speed pulse signals from industrial sites, such as encoder output signals, photoelectric sensor signals, etc., with a counting error of less than 0.1 ‰, providing core guarantees for the precise measurement of equipment motion parameters and meeting the needs of high-precision processing and detection scenarios.

2. Flexible threshold alarm and control functions

Each counting channel supports independent upper and lower threshold settings. When the counting value reaches the preset threshold, the module can quickly output a switch alarm signal or control signal with a response time of less than 10 μ s, achieving real-time protection and linkage control of the device. At the same time, it supports interrupt request function after threshold triggering, which can directly interact with the VME bus controller to ensure timely response of the control system to abnormal working conditions and reduce production losses.

3. Powerful data processing and caching capabilities

Built in high-speed data processing unit and 8KB data cache area can store real-time counting results, frequency parameters, and alarm records, avoiding data loss caused by controller communication delay. Supports two modes of data upload: timed upload and triggered upload. The timed upload cycle can be flexibly configured within the range of 1ms-10s, and the triggered upload can be triggered by threshold events, external signals, or controller instructions to meet the data collection needs in different scenarios.

4. Excellent anti-interference and environmental adaptability performance

Adopting optoelectronic isolation technology and differential signal input design, the input signal isolation voltage can reach up to 2500Vrms, effectively resisting electromagnetic interference, common mode noise, and voltage fluctuations in industrial sites, ensuring stable signal acquisition even in strong interference environments such as high-power motors and frequency converters. The module uses industrial grade components with a working temperature range of -40 ℃~70 ℃, which can adapt to harsh industrial environments such as high and low temperatures, and can operate stably without the need for additional temperature control equipment.

5. Standard VME bus compatibility and scalability

Strictly following the VMEbus Rev. C. standard, it supports 32-bit data bus and 16 bit address bus, and can seamlessly integrate various VME bus controllers and systems without the need for additional adaptation modules. The module provides 4 independent counting channels, each of which can independently configure working modes and parameters, support synchronous counting function between channels, and can be remotely configured and monitored through VME bus for system integration and functional expansion.

6. Convenient debugging and maintenance functions

Equipped with an array of LED status indicator lights, including power indicator lights, channel operation indicator lights, alarm indicator lights, etc., staff can intuitively judge the module power supply status, channel operation status, and alarm information through the indicator lights. Support online debugging and parameter configuration through the VME bus interface. Count data can be read, threshold parameters can be modified, and fault logs can be viewed through GE dedicated configuration software or custom instructions, greatly reducing the difficulty of debugging and maintenance.

Key technical parameters

Product Model

GE VMIVME 2540-300

Bus standard

VMEbus Rev. C.1, 32-bit data bus, 16 bit address bus

Counting channel

4 independent counting channels

Counting resolution

24 digits

Maximum counting frequency

1MHz

working mode

Rising edge counting, falling edge counting, bidirectional counting, frequency measurement, cycle measurement, speed calculation

Input signal type

TTL/CMOS level signal, differential signal

Input isolation voltage

2500Vrms (photoelectric isolation)

output signal

4-channel relay output (alarm/control), contact capacity: 2A@250VAC /30VDC

data caching

8KB high-speed data cache area

response time

Count response ≤ 1 μ s, alarm output response ≤ 10 μ s

Working temperature range

-40℃ ~ 70℃

Storage temperature range

-55℃ ~ 85℃

relative humidity

5%~95% (no condensation)

power supply voltage

+5V DC, ± 12V DC (provided by VME bus)

power consumption

≤ 15W (under full load conditions)

Mechanical dimensions (length x width x height)

160mm × 100mm × 233mm (standard 3U VME module size)

weight

About 0.8kg

Applicable scenarios

The GE VMIVME 2540-300 intelligent counter is widely used in various industrial motion parameter measurement and control scenarios due to its high-precision counting performance, flexible control functions, and excellent anti-interference ability. Typical applications include:

-Machine tool processing and manufacturing: used for spindle speed measurement, tool feed counting, and workpiece machining size positioning in CNC machine tools and machining centers. By collecting encoder signals, precise control of motion accuracy is achieved, improving the dimensional accuracy and qualification rate of machined parts.

-Metallurgy and Rolling Industry: Suitable for measuring coil length, monitoring rolling speed, and tension control in steel plate rolling production lines and aluminum extrusion equipment. It stably collects signals in high temperature and high dust environments to ensure the uniformity and stability of the rolling process.

-Textile and Printing and Dyeing Equipment: Used for yarn length counting in textile machines, fabric feed measurement in printing and dyeing equipment, and vehicle speed monitoring. Through precise counting, yarn and fabric length control is achieved, avoiding material waste and improving production efficiency.

-Printing and packaging machinery: used in printing machines, label machines, packaging machines and other equipment for counting the printing quantity of paper/labels, counting the output of packaging, and monitoring the conveying speed. When the count reaches the preset value, it automatically triggers a shutdown or roll change signal, achieving automated production.

-Logistics and Conveyor System: Used for the counting and positioning of workpieces in automated three-dimensional warehouses and assembly line conveyor systems. By collecting signals from photoelectric sensors or encoders, precise sorting and traceability of goods are achieved, improving logistics efficiency.

-Testing and Measurement Equipment: Used in industrial testing instruments and laboratory testing equipment for pulse signal frequency measurement, motor speed testing, and vibration frequency monitoring, providing high-precision digital data support for product performance testing.

Instructions for use

When selecting, the module adaptability should be determined based on the on-site signal type (TTL/differential), counting frequency, number of channels, and bus system (VME) to ensure that the input signal parameters match the module input specifications and avoid module damage caused by signal overload.

2. Before installation, it is necessary to confirm the power supply voltage and signal compatibility of the VME bus slot. When inserting the module, align it with the slot guide rail, gently push it into place, and lock the fixing screws to avoid poor contact or damage to the bus pins.

3. When wiring, it is necessary to strictly distinguish between the input signal terminals and the power terminals of each channel. The input signal lines should use shielded wires, and the shielding layer should be grounded at one end to avoid parallel laying with the power lines and reduce electromagnetic interference; The output wiring of the relay should match the load capacity to avoid overloading and burning out the contacts.

When initializing the module, it is necessary to set the working mode, counting direction, threshold parameters, and data upload cycle of each channel through configuration software or controller instructions. After the parameter settings are completed, it is recommended to save them to the non-volatile memory of the module to avoid power loss.

5. During use, it is necessary to regularly check the status of the module indicator lights. If there is a channel fault or the alarm indicator light is on, the fault log can be read through the bus to troubleshoot the problem. Common causes of faults include abnormal input signals, incorrect threshold parameter settings, loose wiring, etc.

6. The module should be installed in an environment with good ventilation, no direct sunlight, and no corrosive gases. It should be avoided to install near high-temperature heat sources or locations with severe vibrations. The surface dust of the module should be regularly cleaned to ensure good heat dissipation and extend the service life of the equipment.

7. If the module has faults such as inaccurate counting, no response, or inability to communicate, it should be inspected and repaired by authorized GE after-sales service personnel. It is strictly prohibited to disassemble the module by oneself to avoid damaging the internal circuit or bus interface.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-