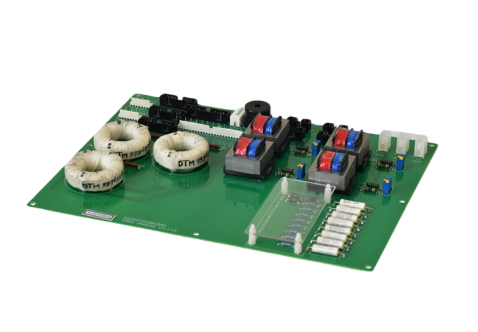

The GE WES13-3 5167-001-0210 mechanical relay output module is a specialized execution layer component developed by General Electric (GE) for industrial automation control systems. It is mainly used to convert weak electrical signals of the control system into strong electrical control signals, and achieve on/off control of external execution devices such as motors, valves, and indicator lights. This module, with its stable mechanical relay structure, widely adaptable working parameters, and reliable industrial grade design, is widely used in fields such as power, metallurgy, manufacturing, and rail transit that require high control accuracy and equipment stability. It is a key bridge connecting control units and actuators in industrial control systems.

GE WES13-3 5167-001-0210 Mechanical Relay Output Module

Module Overview

The GE WES13-3 5167-001-0210 mechanical relay output module is a specialized execution layer component developed by General Electric (GE) for industrial automation control systems. It is mainly used to convert weak electrical signals of the control system into strong electrical control signals, and achieve on/off control of external execution devices such as motors, valves, and indicator lights. This module, with its stable mechanical relay structure, widely adaptable working parameters, and reliable industrial grade design, is widely used in fields such as power, metallurgy, manufacturing, and rail transit that require high control accuracy and equipment stability. It is a key bridge connecting control units and actuators in industrial control systems.

Core technical parameters

model identification

WES13-3 5167-0001-0210

GE industrial control module specific model, including product series, functional codes, and version information

Relay type

Mechanical electromagnetic relay

Adopting a contact mechanical contact structure, it has a clear on/off state and strong anti-interference ability

Number of output channels

3 channels (standard)

Independent channel design, supporting simultaneous control of multiple devices, and electrical isolation between channels

Control signal input

DC 24V level signal

Compatible with mainstream PLC and DCS digital output signals, input current ≤ 10mA

Load voltage range

AC 24V-240V / DC 12V-240V

Wide voltage adaptation, capable of driving AC or DC type loads

Single channel rated load current

5A (resistive load), 2A (inductive load)

Inductive loads need to be matched with surge suppression components to avoid contact damage

Action Time

Suction time ≤ 10ms, release time ≤ 8ms

Quickly respond to control instructions to meet the requirements of medium and high-speed control scenarios

Working environment temperature

-20℃~+60℃

Adapt to harsh environments with high and low temperatures in industrial sites, without condensation

insulation resistance

≥100MΩ(500V DC)

Excellent insulation performance between input and output, as well as between channels, to prevent leakage interference

Installation method

35mm DIN rail installation

Compliant with industrial standard installation specifications, convenient for integration and wiring inside the cabinet

Core Features and Advantages

1. High reliability mechanical structure

The module adopts GE specialized industrial grade mechanical relays, and the contacts are made of silver alloy material, which has excellent arc resistance and wear resistance. The rated operating life can reach more than 100000 times (under resistive load conditions). Compared to solid-state relays, mechanical relays have more advantages in overload capacity, instantaneous surge tolerance, and fault status visualization, making it easier for on-site personnel to quickly determine the working status through contact action sounds or indicator lights.

2. Improved protection mechanism

Multiple protection designs are built into the module: the input side has reverse protection to prevent module damage caused by wiring errors; Integrated overcurrent protection and surge absorption circuit on the output side can effectively suppress the instantaneous high voltage and high current generated during load start stop, and extend the service life of relay contacts. At the same time, the module adopts a sealed shell design as a whole, which has the ability to prevent dust and oil stains, and adapts to the complex environmental conditions of industrial sites.

3. Convenient integration and maintenance

The module adopts a standardized wiring terminal design, with clear labeling of input and output interfaces, supports quick plug and unplug wiring, and reduces installation error rates. The front is equipped with independent channel status indicator lights (red: engaged; green: disconnected), which can provide real-time feedback on the working status of each channel for easy troubleshooting. In addition, the module has a compact size and the rail installation method saves space inside the control cabinet, making it suitable for high-density integration scenarios.

4. Wide compatibility

This module can seamlessly integrate with GE series PLCs (such as RX3i, VersaMax, etc.) and mainstream brand DCS systems. The input signal is compatible with DC 24V standard level, and the output terminal can directly drive various industrial loads without the need for additional intermediate relays or power amplification modules, simplifying the design and wiring process of the control system.

Typical application scenarios

-Power system: used in the secondary circuit of substations to control the opening and closing coils of circuit breakers, the driving mechanism of isolation switches, and the start and stop of signal indicator lights.

-Manufacturing production line: Drive conveyor belt motors, pneumatic valve soleoid coils, heating devices and other actuating components to achieve process automation control.

-Rail transit: applied in the signal system of subway and light rail, controlling the switch switching mechanism and the opening and closing action of platform screen doors.

-Metallurgy and Chemical Industry: Control equipment such as reaction kettle stirring motors, material conveying pumps, temperature control valves, etc., to adapt to harsh environments with high temperatures and high dust.

Installation and wiring precautions

1. Before installation, it is necessary to confirm that the module power supply voltage matches the system to avoid internal circuit burnout caused by overvoltage;

When wiring the output terminal, it is necessary to distinguish the type of load (resistive/inductive). Inductive loads must be connected in parallel with freewheeling diodes to prevent reverse electromotive force from damaging relay contacts;

During the wiring process, it is necessary to ensure that the terminals are securely fastened to avoid excessive contact resistance caused by virtual connections, which can lead to terminal heating;

4. Module installation should be kept away from strong electromagnetic interference sources (such as frequency converters and high-power motors), and shielding measures should be taken if necessary;

5. During maintenance, it is necessary to first cut off the module power supply and load power supply to avoid electric shock or equipment failure caused by live operation.

Common faults and troubleshooting methods

The indicator light of a certain channel is not on, and the load is not moving

Input signal not connected, virtual connection of wiring, burnt relay coil

1. Measure the input terminal voltage with a multimeter and confirm that the signal is normal; 2. Check if the wiring terminals are securely fastened; 3. Replace module channels or module verification

The indicator light is on, but the load does not move

Load failure, output wiring error, relay contact adhesion or burnout

1. Check if the load is normal (such as whether the motor or valve coil is open or closed); 2. Check the output terminal wiring; 3. Measure the on/off status of the output terminal after disconnecting the load

Severe module heating

Load current exceeding the rated value, poor ventilation, and virtual terminal connection

1. Check if the load current is within the specification range; 2. Clean the ventilation openings of the control cabinet to ensure good heat dissipation; 3. Re tighten the wiring terminals

Frequent closing and releasing of relays

Unstable input signal and excessive fluctuation of power supply voltage

1. Observe the input signal waveform with an oscilloscope to eliminate interference; 2. Measure the power supply voltage to ensure it is within the rated range

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-