ABB 216DB61 HESG324063R100/J is a highly reliable distributed controller module in the field of industrial automation. Its core function is to serve as the "decision core" of industrial control systems, receiving real-time data from various sensing devices and input modules on site, completing complex operations and instruction generation based on preset control logic, and then issuing control signals to actuators or output modules to achieve distributed and precise control of industrial production processes. This module belongs to the ABB MasterPiece 200/1 series control system and is a key equipment for achieving decentralized control and centralized monitoring in large industrial scenarios such as chemical parks and power hubs. It is particularly suitable for continuous production processes that require high system redundancy and anti-interference capabilities.

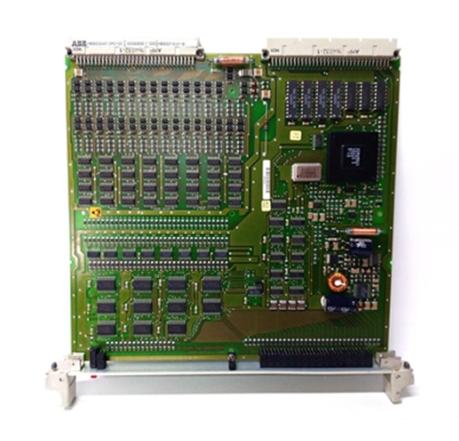

ABB 216DB61 HESG324063R100/J Controller Module

Product core positioning

ABB 216DB61 HESG324063R100/J is a highly reliable distributed controller module in the field of industrial automation. Its core function is to serve as the "decision core" of industrial control systems, receiving real-time data from various sensing devices and input modules on site, completing complex operations and instruction generation based on preset control logic, and then issuing control signals to actuators or output modules to achieve distributed and precise control of industrial production processes. This module belongs to the ABB MasterPiece 200/1 series control system and is a key equipment for achieving decentralized control and centralized monitoring in large industrial scenarios such as chemical parks and power hubs. It is particularly suitable for continuous production processes that require high system redundancy and anti-interference capabilities.

Key technical parameters

Processor configuration

Adopting a 16 bit industrial grade microprocessor with a main frequency of 40MHz, paired with a dedicated control chip, it balances computational efficiency and stability

Storage capacity

Program memory: 128KB EEPROM (erasable, supports permanent program storage); Data storage: 64KB RAM (including backup battery power supply, data retention for ≥ 72 hours in case of power failure)

Input/output capability

Supports 8 digital inputs (DC 24V, response time ≤ 1ms) and 8 digital outputs (DC 24V, maximum load current 1A/channel); Up to 16 I/O submodules can be connected through an expansion bus

Communication interface

1 RS485 differential communication interface (supporting Modbus RTU protocol, communication rate adjustable from 9600-115200bps); 1 dedicated system bus interface (compatible with ABB MasterPiece 200/1 system bus)

Control cycle

The basic control cycle is 10ms, supporting priority scheduling. The critical control task cycle can be set to 5ms to meet the requirements of rapid response

Power specifications

Working power supply: DC 24V (± 20%), power consumption of about 4.5W; equipped with power reverse protection and overvoltage protection functions

Environmental adaptability

Working temperature -25 ° C-70 ° C, storage temperature -40 ° C-85 ° C, relative humidity 5% -95% (non condensing), anti electromagnetic interference level IEC 61000-6-2

Physical specifications

The dimensions (length x width x height) are approximately 150mm x 100mm x 40mm, with a plug-in board design that is compatible with ABB standard 3U rack installation

Compatibility

Compatible with ABB MasterPiece 200/1 series I/O modules (such as AI810 analog input module, AO810 analog output module), supporting communication with ABB Process Portal monitoring software

Core functions and advantages

1. Distributed control and scalability

As a distributed control node, it can independently complete control tasks in local areas (such as a single production line or a single equipment unit), and connect to the central control system through the system bus to achieve "decentralized control and centralized management", reducing the load on the central controller and improving the response speed and stability of the entire system.

Support flexible access to I/O submodules through the expansion bus, with a maximum of 16 different types of input/output modules that can be expanded per module, covering multiple signal types such as digital, analog, pulse, etc., to meet the signal acquisition and control requirements of complex industrial sites. System expansion can be achieved without replacing core modules.

2. High reliability and fault-tolerant design

Industrial grade high stability components (such as capacitance and anti-aging resistance in a wide temperature range) are used to ensure stable operation in extreme environments through high and low temperature cycling tests at -40 ° C to 85 ° C and 1000V insulation withstand voltage tests. MTBF (mean time between failures) exceeds 200000 hours, significantly reducing the risk of production downtime caused by equipment failure.

The data storage is equipped with a backup battery power supply, which can retain critical control data for ≥ 72 hours after power failure. After restoring power supply, the control logic can be restored without reloading the program, ensuring the continuity of the production process; At the same time, it has a hardware watchdog function, which can automatically restart and restore the initial state when the module encounters program abnormalities, avoiding system paralysis.

3. Precise control and flexible programming

Supports multiple types of control algorithms, including switch logic control (such as ladder diagram programming), continuous process control (such as PID regulation, cascade control), batch control (such as batch production process control), and graphical programming can be achieved through ABB Control Builder M programming software. Engineers do not need to master complex code to complete control logic design, reducing development difficulty.

The basic control cycle is as low as 10ms, and the critical task cycle can be set to 5ms, which can quickly capture on-site signal changes (such as pressure fluctuations, temperature fluctuations) and adjust control instructions in a timely manner. For example, in the chemical reaction process, the opening of the feed valve can be adjusted in real time to control the reaction temperature deviation within ± 0.5 ° C, meeting high-precision production requirements.

4. Convenient communication and operation and maintenance

Equipped with RS485 communication interface and supporting Modbus RTU industrial standard protocol, it can directly communicate with field instruments (such as flow meters, pressure transmitters) and actuators (such as frequency converters, regulating valves) without the need for additional protocol converters, simplifying wiring and system integration processes; Simultaneously supporting bidirectional data exchange with central monitoring software, operators can view module operation status and modify control parameters (such as PID settings) in real-time through the monitoring interface.

The front of the module is equipped with LED status indicator lights (power light, running light, fault light, communication light), which can intuitively judge the power supply, running, and communication status of the module. For example, "fault light constantly on" indicates hardware failure of the module, and "communication light flashing" indicates normal communication, making it easy for maintenance personnel to quickly locate problems and shorten troubleshooting time.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-