This module is one of the core components in ABB industrial automation systems, and its model identification includes multiple key codes corresponding to product series, specification parameters, and production information.

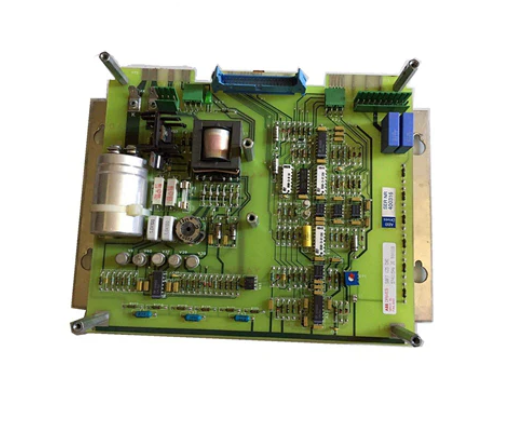

ABB 500MTM02 1MRB150020R0712 1HDF 930512 X010 module

Basic information of module

This module is one of the core components in ABB industrial automation systems, and its model identification includes multiple key codes corresponding to product series, specification parameters, and production information. The specific analysis is as follows:

-Core model: 500MTM02, representing a specific functional module belonging to the ABB 500 series. "MTM" usually refers to multi-purpose control or signal processing related functional positioning;

-Order/Material Code: 1MRB150020R0712, which is an internal standardized material identification used by ABB for production traceability, inventory management, and order matching. "R0712" may represent version number or production batch related information;

-Additional specification code: 1HDF 930512 X010, usually corresponding to the hardware configuration, interface type, or customized parameters of the module. "X010" is often used as a functional subdivision identifier to distinguish different configuration versions within the same series.

This module is widely used in the field of industrial control, such as automation control systems in industries such as power, metallurgy, and chemical engineering, to undertake key tasks such as signal processing, logic control, or equipment interconnection.

Core functions and technical features

1. Core functions

Based on the general characteristics of ABB 500 series modules and the prefix of "MTM" function, it is speculated that the core functions of this module are concentrated in the following areas:

-Multi signal processing capability: supports the acquisition, conversion, and output of analog signals (such as current and voltage signals) and digital signals, and can be adapted to various sensors and actuators in industrial sites;

-Real time control and communication: With high-speed data processing capabilities, it can be connected to ABB's mainstream PLC control systems (such as the AC500 series) and achieve real-time data interaction with other components of the system through standard industrial buses;

-Reliability assurance function: Built in fault diagnosis, signal verification, and redundancy protection mechanism, which can monitor the real-time operation status of modules. When signal abnormalities or hardware failures occur, timely feedback of alarm information can be provided to improve the stability of system operation.

2. Key technical parameters

power input

DC working voltage

24V DC (± 10% fluctuation range)

signal input

Analog input range

4-20mA or 0-10V

signal output

Digital output type

Relay output/transistor output (optional)

working environment

Working temperature range

-20℃ ~ 60℃

communication interface

bus type

PROFINET/Modbus/CANopen (depending on configuration)

Installation and usage precautions

1. Installation requirements

-The module should be installed on a standard DIN rail, and the installation position should avoid direct exposure to high temperature, humidity, dust, and strong electromagnetic interference environments. It is recommended to maintain a distance of at least 10cm from high-power equipment;

-Before wiring, it is necessary to confirm that the power supply voltage matches the rated voltage of the module. Strictly distinguish the power supply and signal input/output terminals according to the module terminal diagram to avoid hardware damage caused by reverse wiring;

-After the module installation is completed, it is necessary to check the tightness of the wiring to ensure stable signal transmission, and reserve a certain amount of heat dissipation space to ensure that the long-term operating temperature of the module is within the allowable range.

2. Debugging and maintenance

-Before the first debugging, it is necessary to configure the module parameters, including signal type, communication address, fault threshold, etc., through ABB dedicated programming software (such as CODESYS or ABB Automation Builder);

-During operation, the module status can be monitored in real-time through the system diagnostic function. If an alarm occurs, priority should be given to investigating the signal line, power stability, and load situation before conducting module hardware testing;

-In daily maintenance, it is necessary to regularly clean the dust on the surface of the module, check the oxidation of the terminals, and avoid signal abnormalities caused by poor contact. The service life of the module can usually reach 5-8 years. If it exceeds the service life, it is recommended to perform performance testing or replacement.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-