The controller module involved in this document is the ABB brand core control unit, with a complete model identification of 500MTM02 and corresponding material codes including 1MRB150020R1102 and 1HDF 930512 X010. It is a key component in ABB's industrial automation control system, mainly responsible for core functions such as signal processing, logic control, and equipment linkage. It is widely used in various automation scenarios in industrial production.

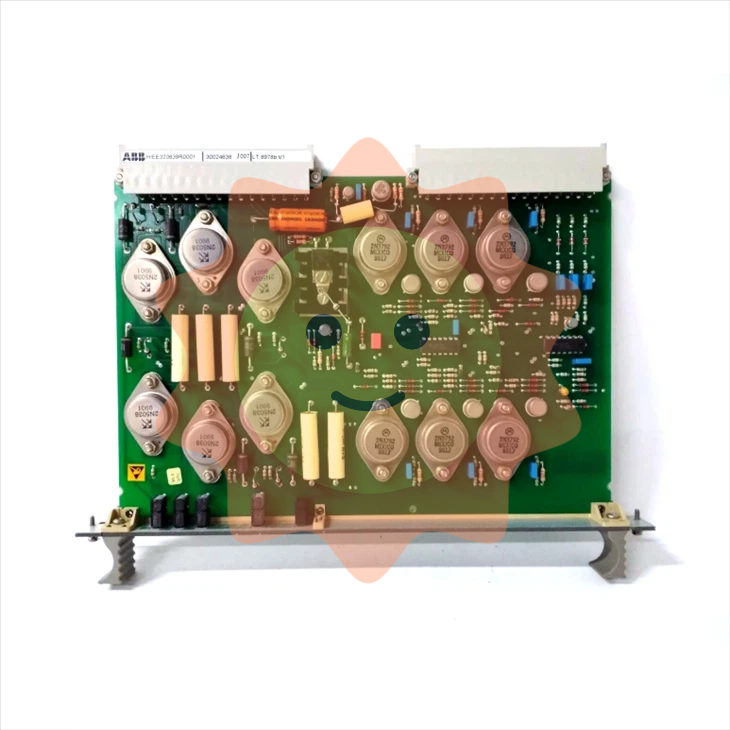

ABB 500MTM02 1MRB150020R1102 1HDF 930512 X010 Controller Module

Basic information of module

The controller module involved in this document is the ABB brand core control unit, with a complete model identification of 500MTM02 and corresponding material codes including 1MRB150020R1102 and 1HDF 930512 X010. It is a key component in ABB's industrial automation control system, mainly responsible for core functions such as signal processing, logic control, and equipment linkage. It is widely used in various automation scenarios in industrial production.

Core technical characteristics

1. Hardware performance

-Processing capability: Equipped with high-performance embedded processors, it has fast data processing and instruction execution capabilities, and can efficiently process multi-channel input and output signals to meet real-time response requirements in complex industrial control scenarios. The control cycle can be as short as milliseconds.

-Storage capacity: Equipped with large capacity high-speed flash memory and RAM, supporting massive control program storage and data caching during operation, ensuring the stability of program operation and data security, and meeting the storage needs of long-term continuous production.

-Interface configuration: Equipped with a variety of standardized interfaces, including digital input/output interfaces, analog acquisition/output interfaces, and communication interfaces (such as Ethernet, RS485, etc.), it can flexibly interface with various sensors, actuators, and upper computer systems to achieve bidirectional transmission and interaction of data.

-Environmental adaptability: Adopting industrial grade protection design, it has a wide temperature working range (usually -20 ℃~60 ℃), can adapt to harsh industrial environments such as dust, vibration, electromagnetic interference, etc., meets relevant industrial protection standards (such as IP20 and above protection level), and ensures stable operation under complex working conditions.

2. Software functions

-Programming support: Compatible with ABB standardized programming environment (such as Control Builder Plus), supports multiple programming languages that comply with IEC 61131-3 standard, including ladder diagram (LD), functional block diagram (FBD), structured text (ST), etc., making it easy for engineers to develop and debug programs according to control requirements.

-Control function: Built in rich control algorithm library, supporting multiple control modes such as logic control, sequence control, process control, etc., can achieve precise control of the production process, and also has functions such as fault diagnosis and alarm processing, which is convenient for equipment maintenance and management.

-Communication capability: Supports multiple industrial communication protocols (such as PROFINET, Modbus, EtherNet/IP, etc.), can seamlessly connect to industrial Ethernet or fieldbus systems, achieve interconnection with other automation equipment and monitoring systems, and build an integrated industrial automation network.

Applicable scenarios

This controller module, with its stable performance and flexible configuration, is widely used in the following industrial fields:

1. Power industry: used in scenarios such as substation automation systems and power equipment control (such as fan and pump control), to achieve equipment monitoring and logical control during power production and transmission processes.

2. Manufacturing industry: In the production lines of automobile manufacturing, mechanical processing, electronic production, etc., undertake tasks such as equipment linkage control, production process automation scheduling, etc., to improve production efficiency and product quality.

3. Chemical industry: Suitable for scenarios such as chemical reactor control and material conveying systems, it has strong anti-interference ability and can ensure control safety and reliability in flammable, explosive, and corrosive environments.

4. Water treatment industry: used for automatic control of sewage treatment and water supply systems, realizing functions such as water quality monitoring, pump start stop, valve adjustment, etc., to ensure the stable operation of the water treatment process.

5. Metallurgical industry: Used for controlling process parameters such as temperature, pressure, and flow rate in the smelting process of steel and non-ferrous metals, adapting to harsh production environments with high temperature and high dust.

Installation and usage instructions

1. Installation requirements

-Before installation, it is necessary to confirm that the module model, material code, and system requirements are consistent, and check that the module appearance is not damaged and the interface is not deformed.

-Installation should be carried out in accordance with the requirements of ABB's official technical manual, ensuring that the installation location is well ventilated, away from strong electromagnetic interference sources and high-temperature heat sources, and firmly fixed to avoid vibration effects.

-When wiring, it is necessary to strictly follow the electrical wiring specifications, distinguish between different types of interfaces such as power and signal, and avoid module damage caused by misconnection. After wiring is completed, insulation testing should be carried out.

2. Operation and maintenance

-Before running the module, it is necessary to complete the program download and parameter configuration through dedicated programming software. Before the first run, a comprehensive functional test should be conducted to ensure the accuracy and correctness of the control logic.

-During daily operation, it is necessary to regularly inspect the modules, check the status of indicator lights, interface connections, and operating temperatures, and record operating data for fault tracing.

-If a module needs to be replaced, the relevant power supply should be cut off first, and the operation should be carried out in the order of "power off first, then disconnect". After replacement, the program and parameter configuration and functional verification need to be re performed.

-The maintenance and repair of modules should be carried out by qualified technicians, strictly following ABB's official maintenance guidelines, and avoiding unauthorized disassembly or modification of the internal structure of modules.

Related identification instructions

The various identifiers in this module have specific meanings for product traceability and selection:

-500MTM02: Module core model, representing product series and specific functional models;

-1MRB150020R1102: ABB internal material code, used for product procurement, inventory management, and traceability;

-1HDF 930512 X010: Supplementary identification, which may represent production batches, configuration versions, or specific application adaptation codes. Specific meanings can refer to ABB product data sheets.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-