This module is a high-precision analog processing unit developed by ABB for industrial automation scenarios. It is identified by HESG437479R1 and HESG437899 dual material numbers (presumably different batches or configuration versions), and its core function is to achieve accurate acquisition, conversion, and transmission of analog signals, providing reliable process data support for control systems.

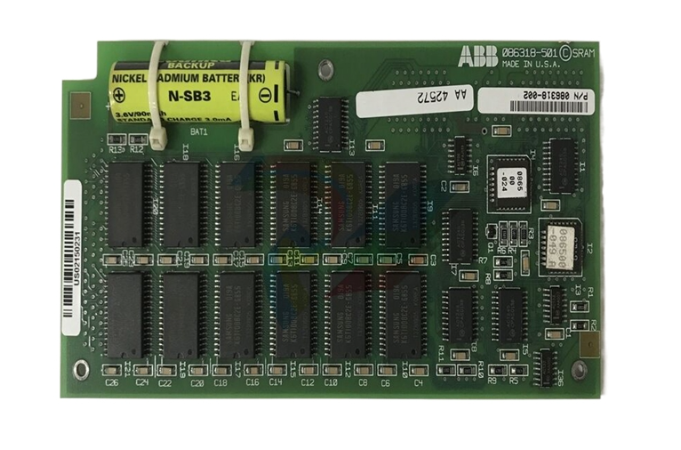

ABB AB91-1 HESG437479R1 HESG437899 Graphics Expansion Module

Product core positioning

This module is a high-precision analog processing unit developed by ABB for industrial automation scenarios. It is identified by HESG437479R1 and HESG437899 dual material numbers (presumably different batches or configuration versions), and its core function is to achieve accurate acquisition, conversion, and transmission of analog signals, providing reliable process data support for control systems.

Key features and advantages

High precision signal processing

Support precise measurement of physical quantities such as temperature, pressure, and flow rate, with minimal error in analog signal output, directly improving the adjustment accuracy and production stability of the control system.

Industrial grade reliability design

Adopting UL 94 V-2 flame retardant shell, suitable for a wide temperature range of -40 ° C to 85 ° C;

Through IEC 60068 standard vibration (2Hz-150Hz, 1g) and impact (15g, 11ms) tests, it can withstand harsh working conditions such as chemical and power plants;

Built in fault diagnosis function, capable of real-time detection of circuit abnormalities and isolation of fault points, reducing the risk of system shutdown.

Flexible integration and maintenance

The size is only 10cm × 5cm × 2cm, supporting 35mm standard guide rail installation (compatible with 7.5mm/15mm depth guide rails), and can be quickly embedded into PLC control cabinets;

Provide spring/screw dual terminal blocks to meet different wiring requirements, and only basic tools are needed for replacement;

Compatible with industrial buses such as Modbus and Profibus, ABB provides exclusive drivers and technical support to simplify integration.

Core technical parameters

Power supply

24V DC

Protection level

IP20 (system level, including terminal and cover closure)

Installation method

Horizontal/vertical guide rail installation, fixed with M4 screws (1.2Nm torque)

Data processing

High speed signal conversion and real-time transmission

Environmental adaptability

Vibration: IEC 60068-2-6; Impact: IEC 60068-2-27

Typical application scenarios

Process Industry Control

Used in chemical and pharmaceutical factories to monitor reactor temperature and pipeline pressure, ensuring production process stability;

Power system monitoring

Real time collection of temperature and vibration data of generators and transformers to prevent equipment overload faults;

Building and Environmental Monitoring

Integrated into building automation systems, regulating air conditioning humidity, fresh air flow, or used for water and air quality monitoring;

Laboratory equipment

Provide high-precision signal acquisition for precision experimental instruments to ensure the accuracy of experimental data.

Practical Operation Guide

1. Installation precautions

The guide rail must comply with the IEC 60715 standard, with a reserved heat dissipation space of at least 5cm between installations;

When wiring, distinguish between analog inputs (such as 4-20mA current signals) and output channels to avoid reverse polarity.

2. Troubleshooting process

Basic inspection: First check the module power indicator light. If it goes out, confirm the integrity of the 24V DC power supply and wiring;

Signal diagnosis: Use a multimeter to check if the input signal is within the range (e.g. temperature signal corresponds to 0-10V);

System troubleshooting: Read the error code through the PLC diagnostic interface and refer to the ABB technical manual to match the cause of the fault (such as signal drift, which may be due to calibration failure).

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-