ABB 07KT98 GJR5253100R0278 is an advanced controller module under the ABB Advant OCS (Open Control System) open control system. It is an industrial grade core control component, originating from Switzerland and commonly used for centralized control and logical operations in large-scale industrial production processes. Its core function is to receive signals from various sensors and actuators on site, process data, make logical judgments and output instructions through built-in control algorithms, and achieve precise control of industrial equipment. It is the "brain center" that ensures stable and efficient operation of production processes.

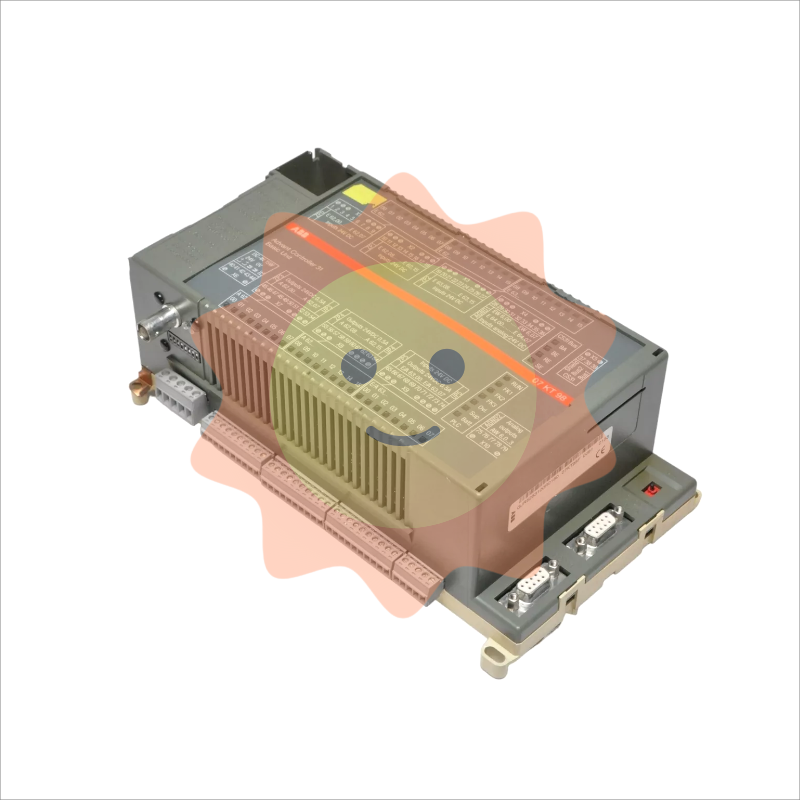

ABB 07KT98 GJR5253100R0278 Advanced Controller Module

Core positioning and basic information

ABB 07KT98 GJR5253100R0278 is an advanced controller module under the ABB Advant OCS (Open Control System) open control system. It is an industrial grade core control component, originating from Switzerland and commonly used for centralized control and logical operations in large-scale industrial production processes. Its core function is to receive signals from various sensors and actuators on site, process data, make logical judgments and output instructions through built-in control algorithms, and achieve precise control of industrial equipment. It is the "brain center" that ensures stable and efficient operation of production processes.

Key technical specifications

Processor model

32-bit high-performance industrial grade processor

Fast computation speed, capable of processing multi-channel data simultaneously, meeting complex control logic requirements

Memory configuration

128MB RAM (running memory)+512MB Flash (storage memory)

Support large capacity program storage and data caching to ensure stable system operation

Communication interface

2 Ethernet interfaces (10/100Mbps), 4 RS485 interfaces, 2 CAN bus interfaces

Flexible connection to the upper computer PLC、 On site instruments and other equipment enable multi device data exchange

Input/output channel

16 analog inputs (4-20mA/0-10V), 8 analog outputs (4-20mA/0-10V), 32 digital inputs (24VDC), 16 digital outputs (24VDC/relay output)

Covering multiple types of signal acquisition and control instruction output, suitable for diverse industrial scenarios

Working voltage

24VDC±10%

Wide voltage design to adapt to power supply fluctuations in industrial sites and improve system anti-interference ability

Working temperature range

-10 ℃ to 60 ℃

Can work stably in medium to high temperature industrial environments without the need for additional constant temperature equipment

Protection level

IP20 (module body)

Suitable for installation inside the control cabinet, it needs to be used in conjunction with the overall protection design of the control cabinet

Programming language support

IEC 61131-3 standard (ladder diagram, functional block diagram, structured text, etc.)

Complies with international programming standards, making it easy for engineers to quickly develop and debug control programs

Typical application areas

Power industry

In the unit control of thermal power plants and hydropower stations, real-time monitoring and adjustment of key parameters such as boiler water level, steam pressure, and turbine speed can be achieved to ensure stable power generation of the generator set, while participating in grid load dispatch and responding to load changes.

Petrochemical industry

Used for process control in petroleum refining and chemical synthesis processes, such as reaction temperature control in catalytic cracking units, liquid level and component regulation in distillation columns, pipeline pressure monitoring, etc., to ensure that the production process meets process indicators, reduce raw material waste and safety risks.

Metallurgical and steel industry

In the ironmaking, steelmaking, and rolling stages of steel production, parameters such as blast furnace air supply temperature, converter oxygen flow rate, rolling mill speed and pressure can be controlled to achieve precise control of steel product quality, improve production efficiency and product qualification rate.

Water treatment industry

For municipal sewage treatment and industrial wastewater treatment systems, the speed of the water pump, the air volume of the aeration equipment, and the dosage of chemicals can be adjusted to achieve automated control of the sewage purification process, ensuring that the effluent quality meets the standards and reducing operational energy consumption.

Key points of installation and operation and maintenance

(1) Installation specifications

It needs to be installed in a standard industrial control cabinet, avoiding direct sunlight, dust accumulation, and contact with corrosive gases. The installation location should reserve at least 5cm of heat dissipation space to prevent module overheating.

When wiring, it is necessary to strictly follow the terminal definition diagram, distinguish between analog and digital quantities and power lines, avoid reversing the positive and negative poles or mixing signal lines with power lines, and reduce electromagnetic interference; After the wiring is completed, it is necessary to tighten the terminal screws to prevent poor contact.

The communication line between the module and other devices needs to use shielded cables, with the shielding layer grounded at one end to reduce the impact of external electromagnetic interference on communication signals.

(2) Debugging and Calibration

Before the initial debugging, it is necessary to check the power supply voltage and wiring correctness, and after confirming that there are no errors, turn on the power; Connect modules through ABB specialized debugging software (such as Control Builder) for program download, parameter configuration, and communication testing.

Calibrate the analog input channel, use a standard signal generator to input standard signals such as 4mA and 20mA, adjust the internal parameters of the module, and ensure that the measured values are consistent with the standard values; Calibrate and correct the analog output channel by measuring the deviation between the output signal and the set value.

During the debugging process, it is necessary to test the accuracy of the control logic one by one, simulate scenarios such as equipment failures and signal abnormalities, and verify whether the alarm function and emergency response logic of the module are normal.

(3) Maintenance strategy

Conduct a monthly visual inspection to check the status of the module indicator lights (which should remain stable or flash regularly during normal operation), whether the terminals are oxidized or corroded, and whether the cables are damaged. If any problems are found, they should be dealt with promptly.

Every quarter, backup module programs and parameters through debugging software to prevent program loss or parameter abnormalities; At the same time, check the stability of the communication link and test whether the data transmission is normal. If there are problems such as packet loss and delay, it is necessary to troubleshoot the line or equipment.

Perform comprehensive maintenance on the module once a year, including cleaning the surface dust of the module (using dry compressed air or a soft brush), re tightening terminal screws, calibrating the accuracy of analog channels, and ensuring long-term stable operation of the module; If the module malfunctions, it is necessary to contact an authorized ABB service provider for repair or replacement to avoid disassembling it on your own.

Selection and substitution instructions

Differences within the same series: The 07KT series controller includes models such as 07KT97, 07KT98, 07KT99, etc. The core differences lie in the number of input/output channels, computational performance, and communication interface configuration. For example, 07KT97 has only 8 analog inputs and 4 analog outputs, making it suitable for small and medium-sized control scenarios; And 07KT98 has more channels and stronger computing power, suitable for medium to large complex control requirements; 07KT99 additionally supports industrial Ethernet protocols such as Profinet for better communication compatibility. The selection should be based on the control scale, signal type, and communication requirements.

Alternative compatibility: This model can directly replace old controllers of the same series (such as 07KT88), but attention should be paid to program compatibility - old programs need to be format converted through ABB software before they can be downloaded to the 07KT98 module; If replacing other brands of controllers, it is necessary to redevelop the control program and confirm whether the input/output signal types and communication protocols match. If necessary, signal conversion modules or communication gateways need to be added.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-