ABB DSAI133A 3BSE018290R1 is a high-precision analog input module in industrial automation control systems. Its main function is to collect, condition, and convert continuous analog signals (such as voltage and current signals) output by various sensors in the industrial field (such as temperature sensors, pressure sensors, liquid level sensors, etc.) into digital signals recognizable by the controller, providing reliable front-end signal input support for precise monitoring, control, and data analysis of industrial processes. This module belongs to the ABB Advant OCS system series and is a key signal processing unit that connects on-site sensing devices with central control systems. It is widely used in industries such as petrochemicals, power, metallurgy, etc. that require high signal acquisition accuracy and stability.

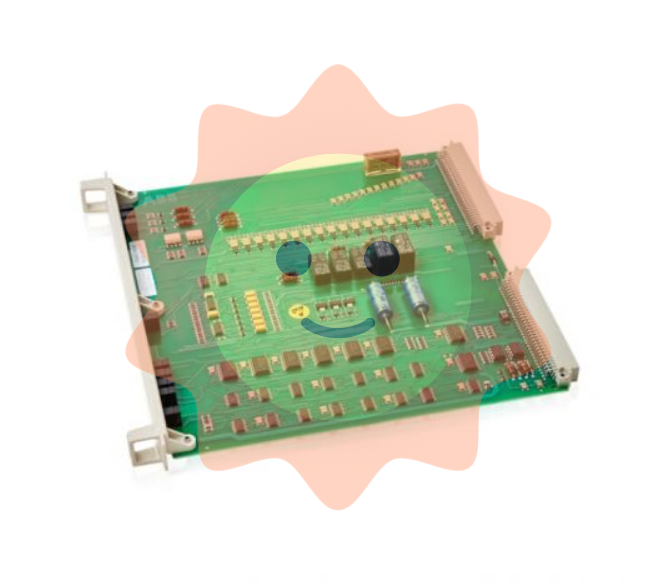

ABB DSAI133A 3BSE018290R1 Analog Input Module

Product core positioning

ABB DSAI133A 3BSE018290R1 is a high-precision analog input module in industrial automation control systems. Its main function is to collect, condition, and convert continuous analog signals (such as voltage and current signals) output by various sensors in the industrial field (such as temperature sensors, pressure sensors, liquid level sensors, etc.) into digital signals recognizable by the controller, providing reliable front-end signal input support for precise monitoring, control, and data analysis of industrial processes. This module belongs to the ABB Advant OCS system series and is a key signal processing unit that connects on-site sensing devices with central control systems. It is widely used in industries such as petrochemicals, power, metallurgy, etc. that require high signal acquisition accuracy and stability.

Key technical parameters

Input channel

8 independent analog input channels, supporting inter channel isolation

Input signal type

Supports DC current signals (4-20mA, 0-20mA) and DC voltage signals (0-5V, 1-5V, 0-10V)

Measurement accuracy

Current signal: ± 0.1% full scale; Voltage signal: ± 0.1% full scale (at a reference temperature of 25 ° C)

Resolution

16 bit A/D conversion resolution ensures precise capture of small signal changes

Sampling rate

The maximum sampling rate for each channel is 100Hz, which can be adjusted through software configuration according to actual needs

Power specifications

Working power supply: 24V DC (± 10%), power consumption of about 3W

Environmental adaptability

Working temperature 0 ° C-60 ° C, storage temperature -40 ° C-85 ° C, relative humidity 5% -95% (non condensing)

Physical specifications

The dimensions (length x width x height) are approximately 100mm x 80mm x 150mm, and are installed using standard rails (35mm DIN rails)

Compatibility

Compatible with ABB Advant OCS system AC 450, AC 800M and other controllers, supporting seamless integration with System 800xA monitoring system

Core functions and advantages

1. High precision signal acquisition and processing

By using a 16 bit high-resolution A/D converter and a high-precision signal conditioning circuit, noise interference is effectively reduced, ensuring the accuracy and stability of analog signal conversion. Even weak signal changes can be accurately detected, meeting the high-precision monitoring needs of key parameters in industrial processes.

Supporting multiple common types of analog input signals, without the need for additional signal conversion modules, different types of on-site sensors can be directly connected, improving the module's versatility and applicability.

2. Reliable industrial grade design

The module has electrical isolation function between channels, with an isolation voltage of 250V AC (effective value), which can effectively prevent signal interference between different channels and damage to the internal circuit of the module by external high voltage, improving the anti-interference ability and operational reliability of the system in complex industrial environments.

Using industrial grade components and undergoing rigorous environmental adaptability testing, it can operate stably in harsh industrial environments such as high and low temperatures, high humidity, etc. The MTBF (mean time between failures) exceeds 100000 hours, reducing equipment downtime and ensuring the continuity of industrial production.

3. Flexible configuration and integration

Support parameter configuration through programming software such as ABB Control Builder M, such as input signal type, sampling rate, alarm threshold, etc. Users can flexibly set according to specific application scenarios, making operation simple and fast.

Following industrial standard communication protocols, it can be easily integrated into ABB Advant OCS control systems, enabling fast data transmission and sharing with controllers and monitoring systems, simplifying system architecture, and reducing system integration difficulty and costs.

4. Comprehensive fault diagnosis and alarm

Built in real-time fault diagnosis function can detect abnormal situations such as module power failure, channel signal overload, A/D conversion failure, etc., and send alarm signals through status indicator lights and system software, making it convenient for maintenance personnel to discover and troubleshoot faults in a timely manner, shortening the time for fault handling.

Each input channel is equipped with an overload protection circuit. When the input signal exceeds the rated range of the module, the relevant circuit can be automatically cut off to avoid module damage and extend the service life of the module.

Typical application scenarios

Petrochemical industry: used to collect simulated signals such as temperature, pressure, and liquid level inside reaction vessels, monitor reaction process parameters in real time, provide data support for production process optimization and safety control, and ensure the stability and safety of chemical production processes.

Power industry: Connect current, voltage, temperature and other sensor signals of generators, transformers and other equipment to achieve real-time monitoring of the operating status of power equipment, timely detect equipment abnormalities, and ensure the reliable operation of the power system.

Metallurgical industry: Collecting simulated signals of temperature, pressure, tension, etc. from steelmaking furnaces, rolling mills, and other equipment to provide accurate data for the automation control of metallurgical production processes, improve the quality and production efficiency of metallurgical products.

Water treatment industry: Monitor water quality indicators (such as pH value, turbidity, etc., with corresponding sensors), water level, flow rate, and other analog signals during the water treatment process to achieve precise control of the water treatment process and ensure that the effluent quality meets the standards.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-