The ABB UFC921A101 digital control module is the core execution and control component in ABB industrial automation control systems. 3BHE024855R0101 is its exclusive hardware identifier, which is the key basis for product production traceability, model accurate matching, and later maintenance support. This module is specially developed for complex industrial control scenarios, with core advantages such as fast computation speed, high control accuracy, and strong compatibility. It is widely used in fields such as power generation, metallurgy, petrochemicals, and rail transit that require extremely high reliability of control logic. It undertakes core tasks such as signal processing, logical computation, equipment regulation, and status feedback, and is the "control center" that ensures stable and efficient operation of industrial production processes.

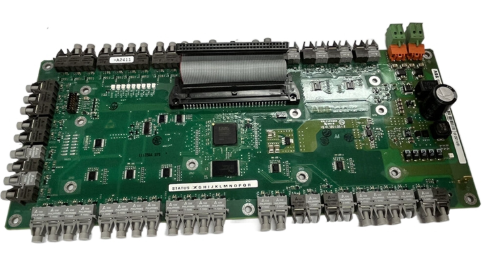

ABB UFC921A101 3BHE024855R0101 Digital Control Module

Basic Product Information

The ABB UFC921A101 digital control module is the core execution and control component in ABB industrial automation control systems. 3BHE024855R0101 is its exclusive hardware identifier, which is the key basis for product production traceability, model accurate matching, and later maintenance support. This module is specially developed for complex industrial control scenarios, with core advantages such as fast computation speed, high control accuracy, and strong compatibility. It is widely used in fields such as power generation, metallurgy, petrochemicals, and rail transit that require extremely high reliability of control logic. It undertakes core tasks such as signal processing, logical computation, equipment regulation, and status feedback, and is the "control center" that ensures stable and efficient operation of industrial production processes.

Core functions and technical features

1. Core control functions

This digital control module is based on a high-performance embedded processor and can meet multi-dimensional industrial control requirements. On the one hand, it has the ability to synchronously collect multiple digital and analog signals, and can receive various signals such as temperature, pressure, flow rate, and voltage from sensors and measuring instruments in real time; On the other hand, through built-in control algorithms such as PID control and logic interlock control, the collected signals are quickly calculated and precise control instructions are output to the executing mechanisms (such as valves, frequency converters, contactors, etc.) to achieve closed-loop control of the production process. At the same time, it supports flexible configuration of control logic and can customize control processes through ABB dedicated programming software according to different production process requirements, adapting to diverse application scenarios.

2. Key technical characteristics

-High speed computing performance: Equipped with a 32-bit high-performance microprocessor, the computing frequency can reach several hundred MHz (specific parameters subject to official specifications), and the entire process of signal acquisition, logic operation, and instruction output can be completed in milliseconds, ensuring real-time response to industrial production processes and avoiding control deviations caused by computing delays.

-High reliability design: using industrial grade components and redundancy design, supporting power redundancy, communication redundancy and other configurations, effectively reducing the risk of single point failure; At the same time, it has a complete overvoltage, overcurrent, and overtemperature protection mechanism, which can automatically cut off dangerous circuits under extreme working conditions, ensuring the safety of modules and related equipment.

-Rich communication interfaces: equipped with various commonly used industrial communication interfaces such as Ethernet, Profibus, Modbus, CANopen, etc., it can seamlessly connect to ABB AC800M, S900 and other series control systems, and support interconnection communication with third-party devices to achieve efficient data transmission and sharing.

-Strong anti-interference ability: The onboard multiple filtering circuit and electromagnetic shielding layer comply with the IEC 61000 series electromagnetic compatibility standard, effectively resisting electromagnetic interference, pulse interference, and radio frequency interference in industrial sites, ensuring stable output of control commands in complex electromagnetic environments.

-Complete diagnostic and alarm functions: It has the ability to diagnose the status of the module itself (such as power supply abnormalities, processor failures) and external device failures (such as sensor disconnection, actuator jamming). When a fault is detected, the alarm information can be uploaded through the communication interface and the local indicator light alarm can be triggered, making it easy for operation and maintenance personnel to quickly locate the problem.

Applicable scenarios and application areas

As the core control unit of industrial control systems, this digital control module plays a key role in multiple fields with its flexible configuration capability and stable control performance. Typical application scenarios include:

1. Power generation industry: used for boiler combustion control, turbine speed regulation, feedwater system control of thermal power units, as well as pitch control and yaw control of wind turbines, to ensure that power generation equipment operates under optimal conditions and improve power generation efficiency and safety.

2. Metallurgical industry: applied to the control of blast furnace ironmaking process in steel plants, temperature and composition regulation of converter steelmaking, rolling speed and pressure control of rolling mills, to achieve precise control of metallurgical processes and ensure the quality of steel products.

3. Petrochemical industry: used for temperature, pressure, and liquid level closed-loop control of chemical reaction vessels, flow regulation and pressure stability control of oil and gas transmission pipelines, and safety interlock control of chemical parks to avoid safety accidents caused by process parameter fluctuations.

4. In the field of rail transit, in conjunction with the traction systems of subways and high-speed trains, power control of traction inverters and braking energy recovery control are achieved, while participating in the logical control of auxiliary systems such as train air conditioning and lighting to ensure the stability and comfort of train operation.

5. In the field of intelligent manufacturing: responsible for robot motion trajectory control, conveyor line speed synchronization control, and logical interlocking of production processes in automated production lines, achieving automation and intelligent control of the production process and improving production efficiency.

Installation and usage precautions

1. Installation specifications

-It needs to be installed in an industrial control cabinet that meets the protection level of IP20 or above, to prevent dust, water vapor, and corrosive gases from entering the interior of the module, and to ensure good ventilation of the control cabinet to provide a suitable working environment for the module.

-During installation, it is necessary to strictly follow the module pin definitions and wiring diagrams for wiring, distinguish between power terminals and signal input/output terminals, and pay special attention to the grounding treatment of the shielding layer of analog signals to avoid module damage or measurement deviation caused by wiring errors.

-The module installation should be fixed with standard guide rails to ensure a firm installation and avoid module looseness or poor wiring contact caused by equipment vibration; At the same time, a minimum 3cm heat dissipation gap should be maintained between modules to prevent high temperature accumulation from affecting performance.

2. Use and maintenance

-Before the first use, it is necessary to complete the configuration, parameter setting, and download of the control logic through specialized programming software such as ABB Control Builder. Before downloading, the configuration logic needs to be simulated and tested to ensure that the control logic is correct.

-In daily operation, it is necessary to regularly monitor the working status of modules through the control system (such as CPU usage, communication status, input and output signals), and promptly troubleshoot any abnormalities found; At the same time, regularly check whether the module wiring terminals are loose to ensure stable signal transmission.

-It is prohibited to plug or unplug wiring or the module itself while the module is live. Before performing maintenance operations, the power supply and related signal circuit power supply of the module must be cut off first, and the operation can only be carried out after the module is completely powered off to prevent static electricity or surge damage to the module.

-Module firmware upgrades must be operated by authorized technical personnel from ABB to avoid using unofficial firmware that may cause module functionality abnormalities; If the module malfunctions, ABB authorized service providers should be contacted for inspection and repair. Disassembling the module by oneself is prohibited.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-