ABB AI02J is a high-performance I/O module that focuses on analog input signal processing. It is mainly used to accurately convert continuous analog signals (such as current and voltage signals) output by field sensors, transmitters, and other devices into digital signals, transmit them to control units such as PLC and DCS, and receive instructions from the control unit while providing feedback on the module's operating status. Its core positioning is "high-precision data acquisition+highly reliable signal transmission", which can adapt to the demanding requirements of complex industrial environments.

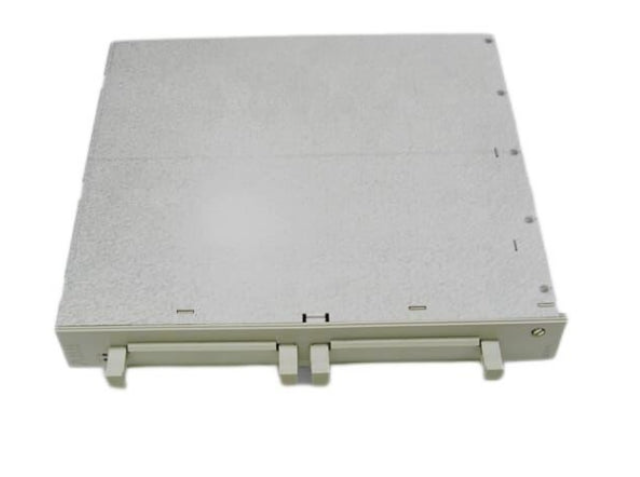

ABB AI02J high-performance I/O module

Module core positioning and application scenarios

ABB AI02J is a high-performance I/O module that focuses on analog input signal processing. It is mainly used to accurately convert continuous analog signals (such as current and voltage signals) output by field sensors, transmitters, and other devices into digital signals, transmit them to control units such as PLC and DCS, and receive instructions from the control unit while providing feedback on the module's operating status. Its core positioning is "high-precision data acquisition+highly reliable signal transmission", which can adapt to the demanding requirements of complex industrial environments.

In terms of applicable scenarios, the AI02J module exhibits strong versatility: in the chemical and petrochemical industries, it can be used to collect key process parameters such as temperature, pressure, and liquid level; In the fields of automobile manufacturing and mechanical processing, it can accurately capture signals such as vibration and speed during equipment operation; In the power system, real-time monitoring of electrical parameters such as voltage and current can be achieved; In addition, in industries such as water treatment and food and beverage that require high process accuracy, data collection can also play a stable role.

Key performance advantages: precision, speed, and reliability

As a high-performance I/O module, AI02J performs outstandingly in core performance indicators, reflecting the core characteristics of "high performance" throughout the entire process from signal acquisition to data transmission.

1. High precision signal acquisition with minimal data error

The AI02J module adopts advanced signal conditioning technology and high-precision AD conversion chip, which can effectively suppress electromagnetic interference, voltage fluctuations and other interference factors in industrial sites, ensuring the accuracy of analog signal conversion. Its analog input accuracy can reach 0.1% FS (full range) level, and some models can achieve higher accuracy acquisition for specific signal types (such as thermocouple and thermistor signals). Whether it is small signal changes or wide range signal fluctuations, the module can accurately capture them, providing reliable data basis for precise decision-making of the control unit and avoiding process deviations or equipment failures caused by data errors.

2. High speed response capability, leading in real-time performance

In industrial automation systems, the real-time nature of data acquisition directly affects the efficiency of executing control instructions. The AI02J module optimizes the signal processing flow and data transmission protocol, with a signal sampling period as low as milliseconds. It can quickly respond to changes in on-site signals and transmit converted digital signals to the control core in a very short period of time. This high-speed response capability is crucial for scenarios such as high-speed production lines and real-time monitoring systems, ensuring that the control unit can timely grasp the on-site status, quickly adjust control strategies, and improve the dynamic control performance of the system.

3. High reliability design, suitable for harsh environments

Industrial sites often have harsh conditions such as high temperature, low temperature, high humidity, high dust, and strong electromagnetic radiation, which place extremely high demands on the reliability of I/O modules. The AI02J module adopts industrial grade components in hardware design, with a wide temperature working range (usually supporting -40 ℃~70 ℃), and can adapt to extreme temperature environments; The module integrates multiple protection mechanisms such as overcurrent protection, overvoltage protection, and short-circuit protection, which can effectively prevent damage to the module caused by abnormal signals on site; At the same time, its shell adopts a sealed dust-proof design, with a protection level of IP20 or above, which can resist dust invasion. In addition, the module has passed EMC (Electromagnetic Compatibility) certification and has strong anti-interference ability, which can operate stably in complex electromagnetic environments and reduce the occurrence of failures.

4. Low power consumption characteristics, energy-saving and environmentally friendly

In the current energy crisis, the energy efficiency of industrial equipment is receiving increasing attention. The AI02J module adopts a low-power design scheme, which effectively reduces the power consumption of the module while ensuring high performance. Compared with traditional I/O modules, its power consumption can be reduced by 10% to 20%. Long term operation can not only reduce energy consumption and operational costs for enterprises, but also reduce module heating, extend module service life, and further improve system stability.

Rich functional features: flexible adaptation, convenient operation and maintenance

In addition to its core performance advantages, the AI02J module also has a series of practical functions that balance the flexibility of system integration and the convenience of later operation and maintenance.

1. Multi signal type adaptation, strong universality

The module supports multiple types of analog input signals, including 4-20mA DC current signals and 0-10V DC voltage signals. Some models are also compatible with temperature signals such as thermocouples (such as K-type and J-type) and thermistors (such as PT100). Users can select the signal type based on the signal output type of the on-site equipment through the configuration software or hardware dip switch of the module. It can adapt to different scenarios without replacing the module, greatly improving the universality and application flexibility of the module, and reducing equipment procurement and inventory costs.

2. Flexible communication and integration methods

The AI02J module supports seamless integration with ABB's mainstream PLCs (such as AC500 series) and DCS systems (such as 800xA series), and transmits data through mainstream industrial Ethernet protocols such as PROFINET, EtherNet/IP, Modbus TCP, or fieldbus protocols such as PROFIBUS, adapting to different automation system architectures. The module adopts standardized installation interfaces, supports rail installation, and can be quickly integrated into the control cabinet, simplifying the installation and wiring work of the system.

3. Comprehensive self diagnosis and fault prompt functions

In order to reduce the difficulty of operation and maintenance, the AI02J module is equipped with a comprehensive self diagnostic function, which can monitor the working status of the module in real time, including power failure, signal abnormality, communication interruption and other types of faults. When a fault occurs, the module will visually indicate the fault status through indicator lights (such as power light, fault light, running light), and upload the fault information to the control unit or upper computer system, making it convenient for operation and maintenance personnel to quickly locate the fault point, shorten the fault investigation time, and improve the system's operation and maintenance efficiency.

4. Convenient configuration and debugging methods

The module is equipped with ABB specific configuration software (such as Control Builder Plus), which allows users to flexibly configure the module's signal type, sampling period, filtering parameters, etc. through the software, without the need for complex programming operations. At the same time, the software also supports online debugging function, and operation and maintenance personnel can view the input and output data and running status of the module in real time, which facilitates parameter optimization and troubleshooting of the module, reducing the difficulty of system debugging and operation and maintenance costs.

Key points for installation and maintenance

To ensure the stable operation of the AI02J module, the following installation and maintenance points should be noted: During the installation process, the module should be installed in a dry and ventilated control cabinet to avoid direct sunlight and rainwater intrusion, while ensuring sufficient heat dissipation space between the module and other high-power devices; When wiring, it is necessary to separate the analog signal line from the power line and power line to reduce electromagnetic interference; The power supply voltage of the module should meet the specification requirements to avoid overvoltage or undervoltage power supply. In daily maintenance, it is necessary to regularly check the status of the module's indicator lights, clean the dust on the surface of the module, and ensure good heat dissipation; If a module malfunction is found, it should be promptly investigated according to the fault prompt, and if necessary, ABB professional technicians should be contacted for repair or replacement.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-