ABB KSD211B (order number: 3BHE022455R1101) is a high-precision Input Coupling Unit (ICU) designed specifically for industrial automation core control systems, belonging to the ABB Symphony Plus Ovation series of key signal processing components. Its core positioning is to serve as a "signal conditioning and isolation hub" between on-site sensors and control systems, specifically responsible for filtering, amplifying, and isolating various analog input signals (such as temperature, pressure, flow, etc.) in industrial sites, converting them into standard signals that can be accurately recognized by the control system, while blocking the transmission of on-site interference signals to the control system. It is widely used in industries such as thermal power, nuclear power, chemical engineering, metallurgy, etc. that require extremely high signal reliability, and is a key basic component to ensure the accuracy of signal acquisition and the safe operation of equipment in control systems.

ABB IC698CPE030/IC698CPE020 series battery cover

Product Overview

ABB KSD211B (order number: 3BHE022455R1101) is a high-precision Input Coupling Unit (ICU) designed specifically for industrial automation core control systems, belonging to the ABB Symphony Plus Ovation series of key signal processing components. Its core positioning is to serve as a "signal conditioning and isolation hub" between on-site sensors and control systems, specifically responsible for filtering, amplifying, and isolating various analog input signals (such as temperature, pressure, flow, etc.) in industrial sites, converting them into standard signals that can be accurately recognized by the control system, while blocking the transmission of on-site interference signals to the control system. It is widely used in industries such as thermal power, nuclear power, chemical engineering, metallurgy, etc. that require extremely high signal reliability, and is a key basic component to ensure the accuracy of signal acquisition and the safe operation of equipment in control systems.

This input coupling unit integrates ABB's mature technology in signal isolation and conditioning, and has the characteristics of high signal isolation, strong anti-interference ability, accurate conditioning accuracy, and good environmental adaptability. In response to the complex electromagnetic environment and multi type sensor access requirements of industrial sites, modular hardware design and dedicated signal processing chips are adopted, which can be seamlessly integrated into ABB Symphony Plus Ovation DCS system. At the same time, it is compatible with mainstream brands of analog sensors, greatly improving the stability and reliability of control system signal acquisition, effectively solving industry pain points such as on-site signal interference and signal attenuation.

Core functions and roles

2.1 Multi type signal adaptation and conditioning

The KSD211B input coupling unit supports multiple commonly used industrial analog input signal types, including 4-20mA DC current signal, 0-10V DC voltage signal, thermistor (PT100/PT1000) and thermocouple (K/J/T/E/R/S type) signals, and can be directly connected to different types of field sensors without the need for additional signal converters. Built in high-precision signal conditioning circuit amplifies weak input signals with low noise and filters signals with superimposed interference to ensure the signal-to-noise ratio and linearity of the output signal. After conditioning, the signal error is ≤ ± 0.05%, providing accurate raw data support for the control system. For example, in temperature monitoring of thermal power boilers, the millivolt level weak signal output by thermocouples can be modulated into a standard 4-20mA signal and transmitted to the DCS system for precise temperature monitoring.

2.2 Efficient electrical isolation and interference suppression

Adopting a three terminal fully isolated design of "input-output power supply", the isolation voltage reaches 2500V AC (1 minute), effectively blocking common mode interference and differential mode interference between field devices and control systems, avoiding measurement errors or equipment failures caused by interference signals entering the control system through signal lines. Built in multi-level EMC protection circuit, with a common mode rejection ratio (CMRR) of ≥ 120dB and a differential mode rejection ratio (DMRR) of ≥ 80dB, capable of withstanding electromagnetic radiation and pulse interference generated by industrial field frequency converters, high-voltage motors, and other equipment. It complies with the IEC 61000-4 series electromagnetic compatibility standards, ensuring stable operation in strong interference environments.

2.3 Signal Diagnosis and Fault Warning

Equipped with comprehensive signal diagnosis function, it can monitor the abnormal status of input signals in real time, including sensor disconnection, short circuit, signal overload and other faults. When a fault is detected, the unit will immediately output a fault signal (dry contact or bus alarm), and at the same time, the fault type will be indicated through LED indicator lights, making it easy for operation and maintenance personnel to quickly locate the problem. For example, when the connected PT100 sensor experiences a disconnection, the "FAULT" indicator light of the unit will remain on, and the corresponding dry contact alarm output will be closed, notifying the control system to activate the corresponding safety plan.

2.4 Redundant design and high reliability operation

Supporting dual power redundant input design, it can connect two independent power sources (DC 24V). When the main power supply fails, it can automatically switch to the backup power supply within 1ms, ensuring continuous operation of the unit without interruption. The unit adopts industrial grade components and undergoes strict environmental adaptability testing (high and low temperature, humidity, vibration, etc.). The mean time between failures (MTBF) is ≥ 100000 hours, meeting the high reliability requirements for continuous operation in industrial sites.

2.5 Flexible integration and convenient debugging

Adopting standard DIN rail installation method, it can be quickly integrated into the I/O cabinet of Symphony Plus Ovation system, and communicate with the system controller through a dedicated bus (such as PROFIBUS DP or EtherNet/IP), supporting online parameter configuration and debugging. Equipped with dedicated debugging interfaces and ABB Engineering Studio configuration software, operation and maintenance personnel can remotely set parameters such as signal type, range, alarm threshold, etc. through the software, without the need for on-site disassembly of equipment, greatly improving debugging efficiency.

Key technical parameters

Order Number

3BHE022455R1101

Product Model

KSD211B

Product Type

Industrial grade analog input coupling unit (ICU)

Input signal type

4-20mA DC, 0-10V DC, PT100/PT1000, K/J/T/E/R/S type thermocouple

Number of input channels

8 independent input channels

Signal conditioning accuracy

≤± 0.05% (full scale)

Isolation performance

Input output power three terminal isolation, isolation voltage 2500V AC (1 minute), isolation resistance ≥ 100M Ω

Anti-interference performance

CMRR≥120dB,DMRR≥80dB; Compliant with IEC 61000-4-2/3/4 standard

output signal

Standard 4-20mA DC or 0-10V DC, supporting bus digital signal output (PROFIBUS DP/EtherNet/IP)

power configuration

DC 24V ± 20%, dual power redundant input, power consumption ≤ 15W

Working temperature range

-25℃ ~ +70℃

relative humidity

5%~95% (non condensing)

Protection level

IP20 (unit body), compatible with Symphony Plus standard cabinet, can reach IP54

Diagnostic function

Support sensor disconnection, short circuit, and signal overload diagnosis, output dry contact alarm and bus alarm signals

Installation method

DIN 35mm standard rail installation

MTBF

≥ 100000 hours

Structure composition and interface description

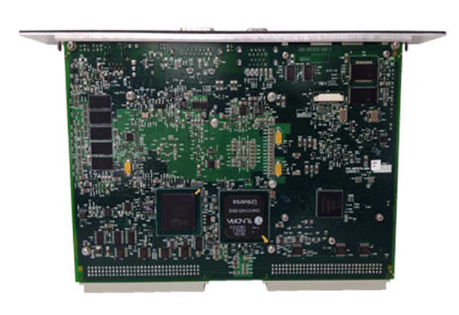

4.1 Core Structure Composition

The KSD211B input coupling unit adopts a high-strength flame-retardant plastic shell and a modular architecture internally. It mainly consists of six core components: firstly, the signal input unit, which includes 8 independent signal input interfaces and adaptation circuits, and can match different types of sensor signals; The second is the signal conditioning unit, which integrates high-precision operational amplifiers and filtering circuits to achieve signal amplification and interference filtering; The third is the isolation unit, which uses optoelectronic isolation chips to achieve electrical isolation between input, output, and power supply, blocking interference propagation; The fourth is the diagnostic unit, which includes signal monitoring and fault judgment circuits, real-time detection of signal status and output fault information; The fifth is the power management unit, which supports dual power redundant inputs and includes power filtering and overvoltage/overcurrent protection circuits to ensure stable power supply; The sixth is the communication and output unit, which includes a bus communication chip and a standard signal output circuit to achieve data exchange with the control system.

4.2 Key Interface and Indicator Light Description

-Power interface: located on the left side of the rear of the unit, in the form of a phoenix terminal, marked with "PWR1" and "PWR2" to distinguish between main and backup power supplies. The input is DC 24V, equipped with a power status indicator light (PWR1/PWR2, green constant light - normal power supply, red light - power failure).

-Signal input interface: Phoenix terminals are used for 8 input channels, arranged in groups of 4 and labeled as "IN1-IN8". Each channel corresponds to a "+" or "-" terminal. The thermal resistance channel is additionally equipped with a "COM" common terminal and supports three wire wiring; The thermocouple channel is equipped with a cold end compensation terminal.

-Signal output interface: The 8 corresponding output channels use Phoenix terminals, labeled "OUT1-OUT8", and output standard 4-20mA or 0-10V signals; 1 bus communication interface (DB9 pin type, labeled "BUS"), supporting PROFIBUS DP or EtherNet/IP communication.

-Alarm interface: 4 dry contact alarm output terminals (Phoenix terminal, labeled "ALM1-ALM4"), can be associated with different types of fault signals, and output a closed signal when a fault occurs.

-Debugging interface: 1 RS-232 debugging interface (DB9 pin type, labeled "DEBUG") and 1 USB interface (front panel), used to connect to a computer for parameter configuration and fault diagnosis.

-Status indicator lights: There are 5 sets of indicator lights at the front of the unit, including power overview light (PWR, green constant light - at least one power supply is normal), running light (RUN, green flashing - normal operation, frequency 1Hz), communication light (COM, green constant light - bus communication is normal, red light - communication failure), channel status light (CH1-CH8, each channel corresponds to 1 indicator light, green - signal normal, yellow - signal overload, red - channel failure), and fault overview light (FAULT, red constant light - fault exists, green constant light - no fault).

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-