The Alstom E64L1 logic information acquisition board is a core data acquisition and processing board designed by Alstom specifically for industrial automation control systems. Its core function is real-time acquisition, filtering, preprocessing, and standardized transmission of various logic signals in industrial sites. As a key data hub of the control system, this board can accurately collect logic signals such as switch values and pulse values. Through the built-in processing unit, signal filtering, level conversion and other preprocessing are completed to convert chaotic on-site signals into standardized data that can be recognized by the upper system. At the same time, it has signal status monitoring and abnormal feedback functions to ensure the accuracy and reliability of data acquisition. It adopts industrial grade high stability components and reinforced electromagnetic shielding design, with excellent anti-interference ability and adaptability to harsh environments. It is widely integrated into automation control systems such as rail transit, energy generation, and industrial manufacturing, providing high-quality logical data support for system decision-making and precise control.

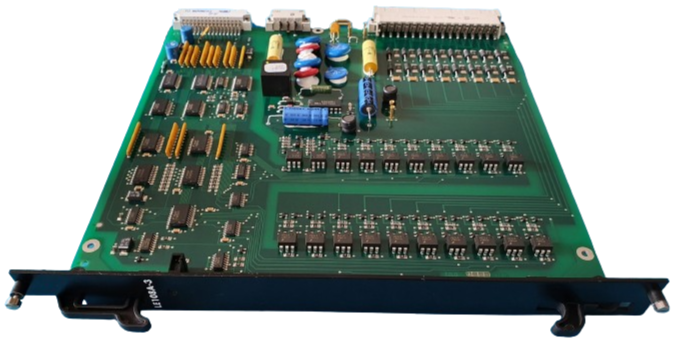

Alstom E64L1- LOGIC INFORMATION ACQUISITION BOARD

Product Overview

The Alstom E64L1 logic information acquisition board is a core data acquisition and processing board designed by Alstom specifically for industrial automation control systems. Its core function is real-time acquisition, filtering, preprocessing, and standardized transmission of various logic signals in industrial sites. As a key data hub of the control system, this board can accurately collect logic signals such as switch values and pulse values. Through the built-in processing unit, signal filtering, level conversion and other preprocessing are completed to convert chaotic on-site signals into standardized data that can be recognized by the upper system. At the same time, it has signal status monitoring and abnormal feedback functions to ensure the accuracy and reliability of data acquisition. It adopts industrial grade high stability components and reinforced electromagnetic shielding design, with excellent anti-interference ability and adaptability to harsh environments. It is widely integrated into automation control systems such as rail transit, energy generation, and industrial manufacturing, providing high-quality logical data support for system decision-making and precise control.

Specification parameters

Based on the technical standards and general specifications for logic information collection of Alstom industrial automation series products, the core specification parameters of Alstom E64L1 logic information collection board are as follows:

-Working voltage: DC 24V ± 10% industrial standard power supply, compatible with control system unified power supply architecture

-Signal collection type: Supports switch quantity (DI) and pulse quantity signal collection, compatible with both NPN/PNP input types

-Number of acquisition channels: 32 isolated digital input channels, supporting multi-channel synchronous acquisition

-Protection level: IP65, with dustproof and anti spray water capabilities, suitable for harsh industrial site environments

-Physical dimensions: 120mm x 100mm x 45mm (length x width x height), standard rail/embedded installation, compatible with general control cabinets

-Interface type: isolated RS-485 communication interface, spring type terminal block, stable connection and convenient wiring

-Communication Protocol: Supports Modbus RTU, Profibus DP, commonly used industrial communication protocols for seamless integration with PLC/DCS systems

-Working environment: temperature -20 ℃~70 ℃, relative humidity ≤ 95% RH (no condensation); Storage temperature -30 ℃~85 ℃

-Acquisition accuracy: signal response time ≤ 1ms, pulse acquisition frequency range 0.1Hz~1kHz, ensuring fast and accurate capture of signal changes

-Power consumption: ≤ 5W, low-power design, reduces overall system energy consumption

-Isolation level: The isolation voltage between the input channel, power supply, and communication interface is ≥ 2500VAC, effectively blocking interference signals from entering

-Electromagnetic compatibility: Complies with the IEC 61000-4 series standards and has strong resistance to electromagnetic interference

Performance characteristics

-Multi channel synchronous acquisition and high-precision response: equipped with 32 isolated input channels, supporting synchronous acquisition of switch and pulse signals of multiple types, with signal response time ≤ 1ms, which can accurately capture rapid changes in on-site signals; The pulse acquisition frequency covers 0.1Hz~1kHz, which can adapt to the logic signal acquisition requirements of different frequency characteristics.

-Strong anti-interference and isolation protection: adopting a full channel optoelectronic isolation design, with an isolation voltage of ≥ 2500VAC, effectively blocking electromagnetic interference and the influence of ground potential difference in industrial sites; Paired with a fully metal shielded casing, it complies with the IEC 61000-4 electromagnetic compatibility standard and can stably collect data even in high voltage and strong electromagnetic interference environments.

-High reliability and environmental adaptability: Industrial grade high stability components and highly integrated circuit designs are selected, resulting in low operating losses and low failure rates; It can work stably for a long time in a wide temperature range of -20 ℃~70 ℃ and high humidity environment, and can adapt to harsh application scenarios such as outdoor and high-temperature workshops.

-Flexible adaptation and convenient integration: compatible with both NPN and PNP input types, it can adapt to different brands of sensors without additional configuration; Supports multiple mainstream industrial communication protocols and can quickly integrate into existing PLC/DCS control systems; Adopting spring type terminal blocks, the wiring is efficient and the contact is reliable, and the maintenance is convenient in the later stage.

-Intelligent signal preprocessing and monitoring: Built in signal filtering circuit can effectively filter out peak pulses and noise interference in on-site signals, improving the purity of data acquisition; Equipped with channel fault self diagnosis function, it can monitor the connection status of the channel in real time, and provide timely feedback when faults such as disconnection and short circuit occur, facilitating quick troubleshooting.

-Convenient installation and operation: supports both rail mounted and embedded installation methods, adapting to different control cabinet layout requirements; The board status indicator light is clear and can intuitively display the power, communication, and signal status of each channel. The operation and maintenance personnel can quickly judge the operation status of the equipment; Low power design reduces heat dissipation requirements without the need for additional heat dissipation devices.

Working principle

The Alstom E64L1 logic information acquisition board is based on the working logic of "multi-channel isolation acquisition intelligent preprocessing standardized transmission status self-monitoring", relying on optoelectronic isolation technology, high-speed signal processing circuits, and embedded control units to achieve accurate and stable acquisition and transmission of industrial field logic signals, providing reliable data input for automation control systems.

The specific workflow is as follows: Firstly, the switch sensors (such as proximity switches and travel switches), pulse signal sources, and other equipment on the industrial site are connected to the 32 isolated input channels of the board through spring type wiring terminals. The board isolates the input signal from the core processing unit through a photoelectric isolation circuit to avoid interference signals from the site affecting the operation of the core circuit; Subsequently, the raw signal received is processed by a built-in filtering circuit to filter out interference signals such as spike pulses and electromagnetic noise, resulting in a pure logical signal; Next, the signal enters the high-speed processing unit to complete level conversion and signal type recognition (distinguishing switch on/off status and pulse frequency), and is converted into standardized digital data; The core microprocessor summarizes and processes the converted digital data, and uploads the collected logical information in real-time to the upper PLC/DCS control system through an isolated RS-485 communication interface according to preset communication protocols such as Modbus RTU; At the same time, the built-in self diagnostic unit of the board continuously monitors the connection status of each input channel, power supply voltage, and communication link status. When a channel disconnection, short circuit, power supply abnormality, or communication interruption is detected, the corresponding status indicator light is immediately driven to sound an alarm, and the fault information is uploaded to the upper system; The upper system can issue parameter configuration instructions to the board through communication protocols to adjust parameters such as signal filtering strength and acquisition frequency, achieving flexible adaptation of acquisition functions.

Precautions

-Installation environment requirements: It should be installed in a ventilated and dry area without severe vibration and impact, ensuring smooth heat dissipation of the board and avoiding close installation with high-power equipment and strong electromagnetic interference sources (such as frequency converters and contactors); If installed outdoors or in environments with high levels of dust, it should be used in conjunction with a sealed control cabinet to prevent dust and moisture from entering the interior of the board; It is prohibited to install in environments with condensation, flammable, explosive, and corrosive gases.

-Electrical connection specifications: Strictly distinguish power terminals, signal input terminals, and communication interfaces according to the wiring diagram, and strictly prohibit misconnection or mixing; Before wiring, it is necessary to confirm that the system is completely powered off. When wiring, it is necessary to wear an electrostatic wristband to prevent static electricity from damaging electronic components; Shielded cables should be used for signal input, with the shielding layer grounded at one end and kept at least 30cm away from the power cable to avoid signal interference; After the wiring is completed, it is necessary to check the tightness of the terminals to ensure that there is no looseness or poor contact. The insulation between the input channel and the power supply should be tested and confirmed to be correct before powering on.

-Power access requirements: The power supply must meet the rated specifications of DC 24V ± 10%, and the power ripple factor must be ≤ 5%; In industrial scenarios with significant power fluctuations, an online regulated power supply should be configured to ensure stable power supply; It is strictly prohibited to connect the power supply in reverse, otherwise it will cause permanent damage to the core components of the board.

-Operation and debugging: Before debugging, it is necessary to carefully read the product manual, familiarize oneself with communication protocol parameters, channel configuration methods, and the meaning of status indicator lights, and have professional technicians operate them; During debugging, first conduct a single point signal test to confirm that the acquisition functions of each channel are normal, and then perform a multi-channel synchronous acquisition test; After the parameter configuration is completed, it needs to be saved to avoid loss due to power failure; It is strictly prohibited to randomly plug and unplug wiring or modify key configuration parameters while in operation.

-Maintenance and upkeep: Regularly clean the board and wiring terminals, remove surface dust and debris, check for oxidation and looseness of the terminals, and tighten or replace them in a timely manner; Regularly verify the accuracy and response time of channel acquisition. If there are issues such as acquisition delay or signal loss, it is necessary to promptly troubleshoot cable and sensor faults; When stored for a long time, the board should be placed in a dry environment of -30 ℃~85 ℃, avoiding damp and high temperature storage. If stored for more than 6 months, it needs to undergo a power on aging test.

-Fault handling: If there is a communication interruption, abnormal channel acquisition, or indicator light alarm on the board, the power should be cut off first, and the power supply voltage, wiring connection, sensor status, and communication link should be checked to see if they are normal. After eliminating external faults, the board should be restarted; If the fault is still not resolved, it is prohibited to disassemble the internal components of the board by oneself. Professional maintenance personnel or manufacturer after-sales service should be contacted for maintenance, and the maintenance process should follow the product warranty agreement; After troubleshooting, it is necessary to conduct channel testing again to confirm that the acquisition function is normal before the system can resume operation.

-Safety operation specifications: The installation, wiring, maintenance, and overhaul of the board are only allowed to be carried out by personnel with professional knowledge and relevant training in industrial automation. Non professionals are strictly prohibited from operating it; During power on operation, it is forbidden to touch the wiring terminals and the core circuit area of the board to avoid electric shock or static damage; When operating in flammable and explosive environments, it is necessary to strictly comply with on-site explosion-proof regulations to prevent safety accidents.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-