The ABB FPX86-9364-A controller motherboard is the core hardware component in ABB industrial automation control systems, designed specifically for high reliability and high real-time industrial control scenarios. This motherboard integrates advanced processor architecture, rich interface resources, and a comprehensive fault diagnosis mechanism, which can stably carry the operation of control programs, achieve collaborative linkage between multiple devices, and accurately respond to various input and output signals on site. It is widely used in automation control systems in fields such as power, metallurgy, chemical engineering, and intelligent manufacturing, and is a key equipment to ensure the continuous, efficient, and safe operation of industrial production processes.

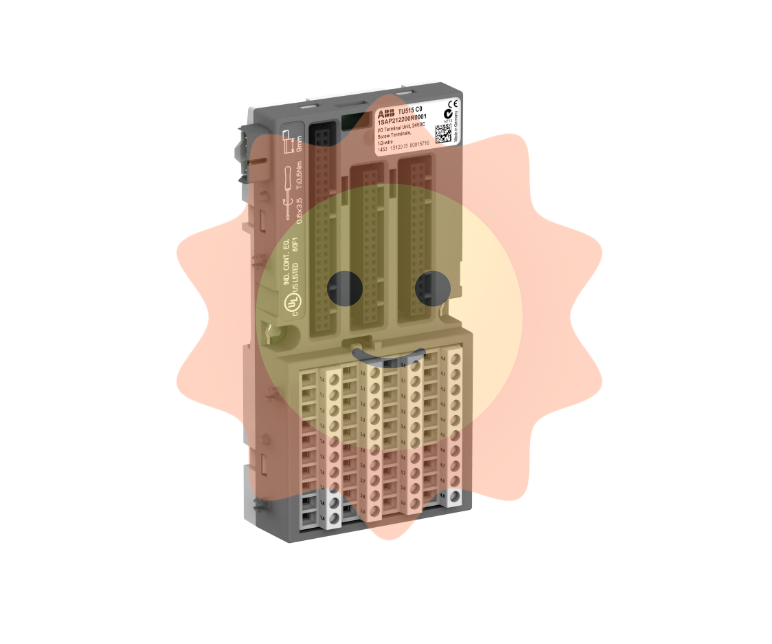

ABB FPX86-9364-A controller motherboard

Product Overview

The ABB FPX86-9364-A controller motherboard is the core hardware component in ABB industrial automation control systems, designed specifically for high reliability and high real-time industrial control scenarios. This motherboard integrates advanced processor architecture, rich interface resources, and a comprehensive fault diagnosis mechanism, which can stably carry the operation of control programs, achieve collaborative linkage between multiple devices, and accurately respond to various input and output signals on site. It is widely used in automation control systems in fields such as power, metallurgy, chemical engineering, and intelligent manufacturing, and is a key equipment to ensure the continuous, efficient, and safe operation of industrial production processes.

Core functions and advantages

2.1 Efficient data processing capability

The motherboard is equipped with a high-performance industrial grade processor, which has powerful instruction processing and data processing capabilities, and supports multitasking parallel processing. Capable of quickly parsing real-time data from on-site devices such as sensors and actuators, executing complex control algorithms (such as PID regulation, logic interlocking, etc.), and outputting control instructions in milliseconds to ensure precise control of industrial production processes, effectively improving production efficiency and product quality.

2.2 Rich interfaces and expansion capabilities

Integrate multiple industrial standard interfaces, including digital input/output (DI/DO) interfaces, analog input/output (AI/AO) interfaces, RS485/RS232 serial communication interfaces, Ethernet industrial Ethernet interfaces, etc., to achieve seamless integration with various field devices such as PLCs, frequency converters, sensors, touch screens, etc. Simultaneously supporting modular expansion, interface modules or functional modules can be flexibly added according to actual control requirements to enhance system compatibility and scalability.

2.3 High reliability and stability

Adopting industrial grade components and rigorous production processes, it has excellent anti-interference ability and environmental adaptability, and can work stably in industrial sites with wide temperature environments ranging from -20 ℃ to 60 ℃, high dust, and strong electromagnetic interference. The motherboard is equipped with a hardware watchdog circuit and a fault self checking module, which can monitor its own running status in real time. When there are program abnormalities, power fluctuations, and other faults, it can quickly trigger a reset or alarm mechanism, reduce the risk of system shutdown, and ensure the continuity of the production process.

2.4 Convenient Debugging and Maintenance

Support the writing, downloading, debugging, and monitoring of control programs through ABB dedicated programming software (such as Control Builder Plus). The software interface is user-friendly, easy to operate, and has functions such as online diagnosis, variable monitoring, and fault alarm recording. The motherboard reserves debugging interfaces and status indicator lights for technicians to quickly locate the fault point, shorten maintenance time, and reduce operation and maintenance costs.

Main technical parameters

processor

Industrial grade high-performance 32-bit processor with a clock frequency of ≥ 500MHz

Memory configuration

Flash memory ≥ 128MB, RAM ≥ 64MB, supports memory expansion

Digital input

16 DI channels, supporting NPC/PNP input, input voltage 24V DC

digital output

8-way DO, relay output, contact capacity 2A/250V AC or 2A/30V DC

Analog input

4-channel AI, supporting 0~10V DC or 4~20mA current input, with an accuracy of ± 0.1%

Analog output

2-channel AO, supports 0~10V DC or 4~20mA current output, accuracy ± 0.2%

communication interface

2 RS485, 1 RS232, 1 Ethernet (supports PROFINET/Modbus TCP)

power input

24V DC ± 10%, power consumption ≤ 15W

working environment

Temperature: -20 ℃~60 ℃; Humidity: 10%~90% (no condensation); Protection level: IP20 (motherboard itself)

Overall dimensions

220mm x 160mm x 40mm (length x width x height)

Installation method

DIN rail installation or screw fixation

Applicable scenarios

-Power industry: used in substation automation systems to monitor and control the status of equipment such as circuit breakers and isolating switches, ensuring stable and reliable power transmission.

-Metallurgical industry: applied in the production process of steel and non-ferrous metals, precise control of temperature, pressure, speed and other parameters of heating furnaces, rolling mills and other equipment is carried out to improve smelting quality.

-Chemical industry: Real time control of process parameters such as liquid level, flow rate, and concentration is achieved in chemical reaction vessels and pipeline transportation systems to ensure that the production process complies with safety regulations.

-Intelligent manufacturing: As the control core of automated production lines, it coordinates the collaborative work of robots, conveyors, detection equipment, etc., to achieve automation and intelligence of production processes.

Installation and usage precautions

Before installation, it is necessary to confirm that the motherboard model is consistent with the system requirements, check the appearance of the motherboard for any damage, and ensure that the components are not loose.

2. The installation environment must meet the technical parameter requirements, avoiding direct sunlight, rainwater immersion, and direct radiation from strong electromagnetic interference sources (such as high-power motors).

3. When wiring, it is necessary to strictly follow the wiring diagram to ensure that the power polarity is correct, the interface connection is firm, and to avoid short circuits or poor contacts.

Before the first use, it is necessary to complete system configuration and program download through programming software, confirm that the parameter settings are correct, and then put it into operation.

5. During daily maintenance, it is necessary to regularly clean the dust on the surface of the motherboard, check the interface connection status and status indicator lights, and promptly shut down for troubleshooting if any abnormalities are found.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-