GE IS200SDIIH1ADB (part number MRP683026) is a high-performance contact input isolation terminal board launched by General Electric (GE), belonging to the core component of GE Speedtronic Mark VIe control system series. This product is designed specifically for industrial automation scenarios, mainly responsible for the collection, isolation, and transmission of contact signals. It can electrically isolate the switch signals of on-site equipment (such as the contact status of sensors, contactors, buttons, etc.) and stably transmit them to the core module of the control system, providing reliable signal guarantee for equipment operation status monitoring and logic control. Its design strictly follows industrial standards and has strong anti-interference ability, stability, and environmental adaptability. It is widely used in industries such as power, petrochemicals, metallurgy, and papermaking that require extremely high reliability of control systems.

GE IS200SDIIH1ADB MRP683026 Contact Input Isolation Terminal Board

Product Overview

GE IS200SDIIH1ADB (part number MRP683026) is a high-performance contact input isolation terminal board launched by General Electric (GE), belonging to the core component of GE Speedtronic Mark VIe control system series. This product is designed specifically for industrial automation scenarios, mainly responsible for the collection, isolation, and transmission of contact signals. It can electrically isolate the switch signals of on-site equipment (such as the contact status of sensors, contactors, buttons, etc.) and stably transmit them to the core module of the control system, providing reliable signal guarantee for equipment operation status monitoring and logic control. Its design strictly follows industrial standards and has strong anti-interference ability, stability, and environmental adaptability. It is widely used in industries such as power, petrochemicals, metallurgy, and papermaking that require extremely high reliability of control systems.

Core functions and advantages

1. Efficient contact signal acquisition and isolation

As the core function of the contact input terminal board, this product supports the simultaneous acquisition of multiple contact signals. Each input signal adopts an independent isolation circuit design, and the isolation voltage can reach thousands of volts (specific parameters can be found in the technical specifications section). It can effectively block electrical interference and common ground problems between the field side and the system side, avoid damage to the core components of the control system due to field signal fluctuations, surges, or grounding abnormalities, and significantly improve the reliability of signal transmission.

2. Strong anti-interference ability

In response to the complex electromagnetic environment of industrial sites, IS200SDIIH1ADB adopts multiple anti-interference designs: on the one hand, signal isolation is achieved through optoelectronic or magnetic isolation technology, and on the other hand, the circuit board adopts optimized layout and shielding design, which can resist electromagnetic radiation (EMI) and electromagnetic compatibility (EMC) interference, ensuring accurate acquisition and transmission of contact signals in strong electromagnetic interference environments (such as near high-power motors and frequency converters), avoiding control logic disorder caused by signal misjudgment.

3. Compatible with GE Mark VIe control system

This terminal board is a specialized component for the GE Speedtronic Mark VIe control system, which has perfect hardware compatibility and communication matching with the controller modules within the system (such as other modules in the IS200 series). It can be quickly integrated without the need for additional adapter devices, simplifying the system construction process and reducing integration costs.

4. Industrial grade reliability design

The product adopts industrial grade component selection and supports a wide working temperature range (usually -40 ℃~70 ℃, subject to actual parameters), which can adapt to harsh industrial environments such as high temperature, low temperature, humidity, and dust. At the same time, it has overvoltage and overcurrent protection functions. When there is an abnormal peak in the on-site signal, the abnormal circuit can be quickly cut off to protect the terminal board and backend control system from damage.

5. Convenient installation and maintenance

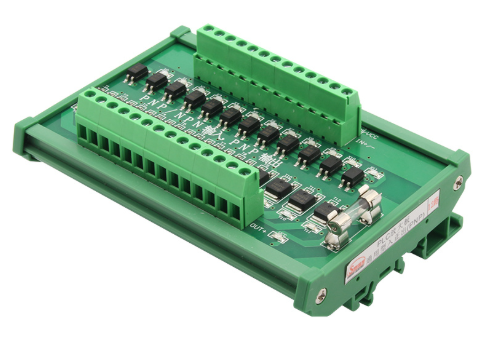

The terminal board adopts a standardized guide rail installation method, which complies with industrial equipment installation specifications and is easy to quickly fix and disassemble. The wiring terminal adopts a crimping design, which is firm and easy to operate. At the same time, the input channel number, wiring terminal definition, and indicator light identification are clearly marked on the board, making it convenient for on-site engineers to conduct signal troubleshooting, fault diagnosis, and daily maintenance.

Key technical parameters

Product Model

IS200SDIIH1ADB

Material Number (MRP)

six hundred and eighty-three thousand and twenty-six

input type

Dry contact/wet contact input (compatible)

Number of input channels

Usually 16/32 channels (depending on product specifications)

isolation method

Optoelectronic isolation/magnetic isolation

isolation voltage

Input output: 2500Vrms (1 minute); Input ground: 1500Vrms (1 minute)

working power supply

DC 24V (typical value, compatible with ± 10% fluctuation)

Input signal voltage range

DC 0V~30V (wet contact); Dry contacts support passive signals

response time

≤ 1ms (signal delay from input to output)

Working temperature range

-40 ℃~70 ℃ (operation); -40 ℃~85 ℃ (storage)

humidity range

5%~95% (no condensation)

Installation method

35mm DIN rail installation

Applicable scenarios

The IS200SDIIH1ADB terminal board, with its high reliability and strong compatibility, is mainly used in industrial equipment with GE Mark VIe control system as the core. Typical scenarios include:

-Power industry: turbine control and boiler auxiliary control for thermal power units, such as status signal acquisition for feedwater pumps and fans;

-Petrochemical industry: monitoring the valve switch status of equipment such as reaction vessels and heat exchangers, and collecting pump operation signals;

-Metallurgical industry: collection of start stop signals and fault contact signals for rolling mill equipment and conveyor belt systems in the steel production process;

-General Industry: Transmission and isolation of equipment interlocking signals and safety protection contact signals (such as emergency stop buttons and safety door contacts) for large-scale production lines.

Installation and usage precautions

Before installation, it is necessary to confirm that the product model matches the control system and verify whether the material number MRP683026 is consistent with the purchase list;

During the installation process, it is necessary to strictly follow the electrical wiring specifications, distinguish between input terminals, power terminals, and grounding terminals, and avoid equipment damage caused by wiring errors;

After the wiring is completed, insulation testing is required to ensure that the insulation performance between the input circuit and the system circuit meets the requirements;

4. During operation, it is necessary to regularly check the status of the indicator lights on the terminal board (such as power lights and channel signal lights), and quickly determine the equipment's operating status through changes in the indicator lights;

5. During maintenance, the working power supply of the terminal board should be cut off first to avoid safety accidents or equipment failures caused by live operation.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-