YASKAWA JANCD-JSP04-1 is a high-performance CNC board launched by Yaskawa (YASKAWA) brand. Its core positioning is the core control and multi axis linkage management of the CNC system, with powerful CNC instruction parsing, axis motion control, and machining process monitoring capabilities. It can achieve trajectory planning, speed adjustment, and precise positioning for complex part machining. This board adopts a modular structure design, compatible with Yaskawa ∑ series servo systems and mainstream CNC equipment, supports multiple CNC programming formats, and has excellent environmental adaptability and operational stability. It is a core component for improving the machining accuracy of CNC machine tools, optimizing machining efficiency, and ensuring smooth production processes. At present, there is sufficient stock supply of this model of CNC board, which can meet diverse needs such as supporting new CNC machine tools, upgrading and maintaining existing CNC equipment.

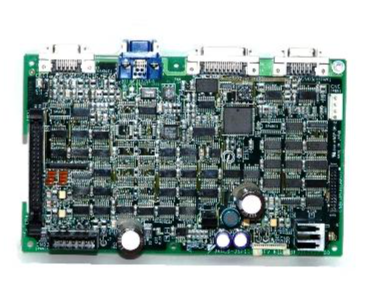

YASKAWA JANCD-JSP04-1 CNC board

Product Overview

YASKAWA JANCD-JSP04-1 is a high-performance CNC board launched by Yaskawa (YASKAWA) brand. Its core positioning is the core control and multi axis linkage management of the CNC system, with powerful CNC instruction parsing, axis motion control, and machining process monitoring capabilities. It can achieve trajectory planning, speed adjustment, and precise positioning for complex part machining. This board adopts a modular structure design, compatible with Yaskawa ∑ series servo systems and mainstream CNC equipment, supports multiple CNC programming formats, and has excellent environmental adaptability and operational stability. It is a core component for improving the machining accuracy of CNC machine tools, optimizing machining efficiency, and ensuring smooth production processes. At present, there is sufficient stock supply of this model of CNC board, which can meet diverse needs such as supporting new CNC machine tools, upgrading and maintaining existing CNC equipment.

Specification parameters

-Core electrical parameters: rated voltage DC 24V, rated power consumption ≤ 30W; equipped with a 32-bit high-performance processor, instruction processing speed up to 1 μ s/step, supporting multi axis linkage control (maximum support for 4-axis linkage); The positioning control accuracy reaches ± 1 pulse, suitable for high-precision CNC machining requirements; The working temperature range is 0 ℃~40 ℃, ensuring stable operation in CNC machining scenarios.

-Control interface: Equipped with MECHATROLINK-III high-speed servo communication interface, the communication speed can reach up to 100Mbps, enabling real-time data exchange with servo drives; Equipped with RS-485 communication interface, supporting Modbus RTU protocol, used to connect external devices such as operation panel and handwheel; Provide multiple digital I/O interfaces (24 inputs/16 outputs) for connecting auxiliary control components such as limit switches and emergency stop buttons.

-Output performance: Supports pulse/direction signal output, with a maximum pulse frequency of 1MHz, compatible with Yaskawa ∑ - V, ∑ - VI series servo drives; Equipped with overload protection, position deviation protection and other functions, it can quickly respond to abnormal states during the machining process, protecting the safety of CNC equipment and workpieces; Support spindle speed control signal output to achieve coordinated linkage between spindle and feed axis.

-Certification standards: Passed CE and UL international safety certifications, in compliance with industrial equipment safety operation standards.

-Physical parameters: Weight of approximately 500g, size in accordance with the standard installation specifications for CNC systems (160 × 100 × 30mm); The protection level reaches IP20, suitable for installation environment inside the electrical cabinet of CNC machine tools, effectively preventing dust and foreign objects from entering, and suitable for industrial scenarios such as mechanical processing workshops.

Performance characteristics

-High precision multi axis linkage control: relying on a 32-bit high-performance processor and high-speed servo communication interface, precise synchronous control of multi axis linkage is achieved, with high trajectory planning accuracy, which can meet the machining needs of complex surfaces and irregular parts; Support electronic gear and electronic cam functions, achieve flexible synchronization between the spindle and feed shaft, and improve the surface quality of machining.

-Strong environmental adaptability and high reliability: using industrial grade high stability components and anti-interference circuit design, it has good electromagnetic interference suppression ability. Through electromagnetic compatibility (EMC) testing, it can operate stably in complex electromagnetic environments such as mechanical processing workshops; Equipped with comprehensive power fluctuation suppression function, it can adapt to slight voltage fluctuations in industrial power grids.

-Convenient integration and debugging: Provides detailed installation guidance and simplified setup process, supports seamless compatibility with various industrial automation systems, and can efficiently complete integration whether building new systems or upgrading old systems.

-Comprehensive fault diagnosis and convenient maintenance: It has a complete fault self diagnosis function, which can detect servo communication abnormalities, excessive position deviation, overload, emergency stop triggering and other fault states in real time. It sends alarm signals through LED indicator lights and communication interfaces, and records fault codes; Support online parameter modification and debugging, parameter optimization can be completed without disassembling modules, greatly reducing maintenance difficulty and downtime losses.

-Safety compliance: Complies with international safety standards and electromagnetic compatibility requirements, comes with a comprehensive electrical protection design, and reduces equipment operational risks.

Working principle

The YASKAWA JANCD-JSP04-1 CNC board is the core control unit of the CNC machine tool system, and its working principle is based on the full process CNC control logic of "instruction reception trajectory planning axis linkage control state feedback fault diagnosis". Firstly, the CNC board receives CNC programming instructions (G code, M code, etc.) from the operation panel or upper computer through a communication interface; Subsequently, the internal 32-bit high-performance processor performs high-speed parsing of CNC instructions, combines the parameters of the machined parts to complete trajectory planning and axis motion parameter calculation, and generates position and speed control instructions for each axis; Next, the control instructions are transmitted in real-time to each servo drive through the MECHATROLINK-III high-speed servo communication interface, driving the servo motor to move according to the planned trajectory and achieving multi axis linkage machining; At the same time, the CNC board real-time collects the actual position, speed signals, limit, emergency stop and other auxiliary signals of each axis, compares them with the set values, dynamically corrects control instructions, and ensures machining accuracy; In addition, the internal fault diagnosis circuit continuously monitors the operating status. Once an abnormality is detected, an alarm is immediately triggered and a fault code is recorded to stop the machining action and protect the safety of the equipment and workpiece.

Precautions

-Voltage matching and power protection: Before installation, it is necessary to confirm that the power supply voltage is consistent with the rated voltage of the module (DC 24V) to avoid voltage fluctuations exceeding the allowable range of ± 10%; It is recommended to install surge protectors and filters at the power input end to prevent damage to the internal circuit of the module caused by power grid surges and electromagnetic interference; When not in use for a long time, the power should be disconnected to avoid component aging caused by standby current.

-Safety operation regulations: When wiring, repairing or replacing components, the power must be disconnected first, and touching the terminals while powered on is strictly prohibited to prevent electric shock accidents.

-Correct wiring and communication configuration: Strictly distinguish power interfaces, servo communication interfaces, and I/O interfaces according to the wiring manual, strictly prohibit misconnection and mixing, and avoid permanent damage to the module; Ensure that the terminals are securely fastened during wiring to prevent loose connections or communication interruptions; The servo communication cable should use Yaskawa special shielded cable, and the distance between the power cable and the signal cable should be ≥ 300mm to reduce signal interference; Based on the servo motor model and processing requirements, accurately configure key parameters such as shaft parameters and electronic gear ratios to ensure multi axis linkage accuracy.

-Standardize grounding settings: The grounding terminals must be strictly connected according to local grounding regulations to avoid sharing grounding with welding machines, motors, and other equipment. When multiple modules are used side by side, they must be independently grounded, and grounding wire circuits are prohibited to prevent electric shock or fire risks.

-Professional operation: The parameter setting, system integration, and fault maintenance of modules need to be completed by professional technicians to avoid system failures or equipment damage caused by non professional operations.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-