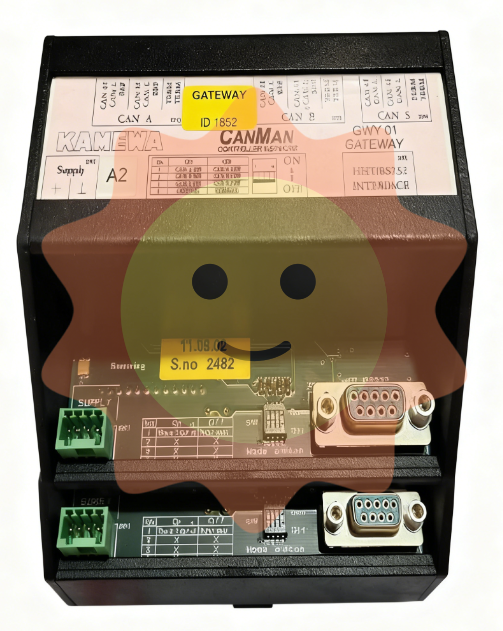

Rolls-Royce KMW 902650 - PCB CARD

The Rolls-Royce KMW 902650 stands as a pinnacle of engineering excellence within the realm of industrial automation, specifically tailored to meet the rigorous demands of the power industry, petrochemical sector, and general automation applications. Engineered for superior input/output capacity, durability, and unmatched performance, the KMW 902650 delivers a robust solution for complex automation challenges where reliability and precision are paramount. At its core, the Rolls-Royce KMW 902650 features an advanced control interface that supports high-capacity data throughput with input/output channels optimized for rapid response and multi-signal processing. This model is designed to handle a wide voltage range and maintain operational integrity under extreme environmental conditions, ensuring consistent performance in high-stress industrial environments. The KMW 902650 boasts a modular design that facilitates easy integration with existing systems, while its rugged construction ensures long-term durability even in corrosive or high-temperature settings typical of petrochemical plants and power generation facilities. Performance metrics of the KMW 902650 highlight its capacity to process complex control commands with minimal latency, supporting automation workflows that require both speed and accuracy.

Its enhanced signal fidelity and noise immunity ensure error-free operation, essential for mission-critical automation tasks. Moreover, this model incorporates advanced diagnostics and remote monitoring capabilities, enabling predictive maintenance and reducing downtime. The combination of these features makes the KMW 902650 an indispensable asset for operators seeking to optimize efficiency and safety in their automation processes. In real-world applications, the Rolls-Royce KMW 902650 excels particularly in power industry settings, where it manages control systems for turbines, generators, and grid automation with precision and reliability. Its resilience to electromagnetic interference and capability to operate seamlessly under fluctuating load conditions make it ideal for power plants ranging from traditional coal-fired stations to renewable energy installations. Within the petrochemical industry, the KMW 902650 reliably controls complex process automation systems, including chemical reactors, distillation columns, and safety shutdown sequences, where failure is not an option. Additionally, in general automation contexts—such as manufacturing plants and large-scale facility management—the KMW 902650 integrates smoothly with diverse automation equipment, providing a centralized, dependable control hub that enhances operational throughput and safety.

When compared to other Rolls-Royce automation products, the KMW 902650 offers unique advantages in scalability and environmental resilience. For instance, while the Rolls-Royce RRRLY8 and RRPWR2006 models provide robust control functionalities, the KMW 902650 extends these capabilities with enhanced input/output density and superior diagnostics. Unlike the Rolls-Royce MPC-200 (A 7021100) and MPC-300, which focus on modular programmable control, the KMW 902650 excels at handling high-volume, real-time data streams critical for power and petrochemical processes. Furthermore, its rugged design outperforms models such as the Rolls-Royce 5801-SD100C and Rolls-Royce BRUNVOLL in harsh operational environments, ensuring extended service life and reduced maintenance intervals. Alongside the Rolls-Royce KMW 902650, we also offer complementary automation solutions such as the Rolls-Royce CANMAN SLIO 02 and Rolls-Royce DC 0015D to provide enhanced communication and signal interface capabilities within integrated control systems. For applications requiring precise thrust or positioning control, the Rolls-Royce Bow Thruster and Rolls-Royce KAMEWA R160637A models serve as ideal mechanical complements.

Additionally, the Rolls-Royce STC-1 and Rolls-Royce POSCON V.3 can be paired with the KMW 902650 to extend system control complexity, particularly in multi-unit industrial setups. The inclusion of the Rolls-Royce G2 JOYSTICK and Rolls-Royce AQM 4 LSP007 further enables intuitive manual override and monitoring functionalities, enhancing operational flexibility. The application of KMW 902650 in power industry, petrochemical, and general automation sectors is bolstered not only by its technical superiority but also by its seamless integration with the broader portfolio of Rolls-Royce automation products. This synergy allows operators to build highly customized, scalable automation architectures that meet evolving operational requirements. Whether upgrading legacy installations or deploying state-of-the-art industrial control systems, the KMW 902650 ensures a future-proof investment with proven reliability and performance. In summary, the Rolls-Royce KMW 902650 is a cutting-edge automation controller that redefines industry standards for input/output capacity, durability, and operational excellence in demanding industrial environments. Its adaptability across power generation, petrochemical processing, and general automation applications, combined with its compatibility with other Rolls-Royce models like the RRRLY8, MPC-200, CANMAN SLIO 02, and Bow Thruster, makes it a versatile and indispensable component in modern industrial control systems.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-