YOKOGAWA LC82 * A is a high-performance industrial controller launched by Yokogawa Electric in Japan, belonging to the core product series of Yokogawa Industrial Automation Control Systems. As the "core computing and control center" of industrial automation systems, this controller has powerful logical computing, process control, and data processing capabilities, which can achieve real-time monitoring, precise regulation, and interlocking protection of various process parameters in industrial production processes. By seamlessly collaborating with various I/O modules and bus node units, a complete distributed control system (DCS) is constructed to provide core control support for stable production in key industrial fields such as chemical, power, metallurgy, and petroleum refining.

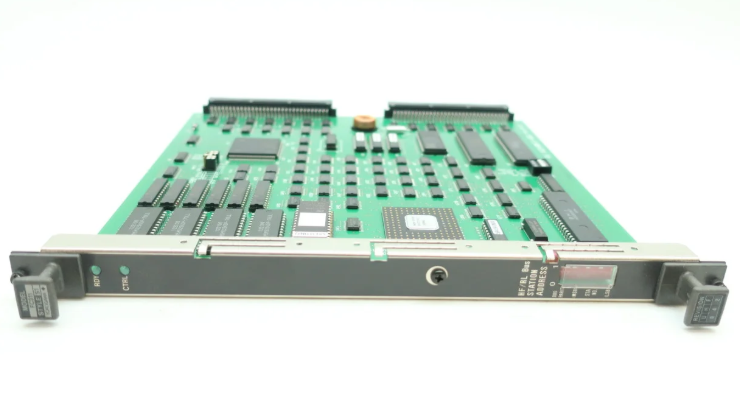

YOKOGAWA LC82 * A Industrial Controller

Product Overview

YOKOGAWA LC82 * A is a high-performance industrial controller launched by Yokogawa Electric in Japan, belonging to the core product series of Yokogawa Industrial Automation Control Systems. As the "core computing and control center" of industrial automation systems, this controller has powerful logical computing, process control, and data processing capabilities, which can achieve real-time monitoring, precise regulation, and interlocking protection of various process parameters in industrial production processes. By seamlessly collaborating with various I/O modules and bus node units, a complete distributed control system (DCS) is constructed to provide core control support for stable production in key industrial fields such as chemical, power, metallurgy, and petroleum refining.

The LC82 * A industrial controller adopts a high-performance processor architecture and redundant design (optional), with high reliability, strong anti-interference ability, and flexible expansion characteristics. After rigorous industrial environment adaptability testing, it can operate stably in complex industrial scenarios such as high temperature, high electromagnetic interference, and multiple dust. It supports multiple industrial communication protocols and can seamlessly integrate with Yokogawa's full range of I/O modules and third-party compatible devices, adapting to industrial control requirements of different scales and processes. It is a key core equipment for achieving automation and intelligent control in modern industrial production processes.

Core technical parameters

The technical parameters of the LC82 * A industrial controller have been accurately calibrated and rigorously tested to ensure computational performance, control accuracy, and operational stability. The specific detailed parameters are as follows:

(1) Core operational parameters

Processor performance: Equipped with high-performance industrial grade processors, supporting high-speed logic operations and process control algorithms, basic instruction processing speed reaches microsecond level, ensuring fast execution of control instructions;

Memory configuration: Equipped with large capacity program memory and data memory, the program memory capacity meets the requirements of complex control logic programming, and the data memory can store a large amount of real-time process parameters and historical data;

Control cycle: Supports flexible configuration of control cycles, with a minimum control cycle as low as 10ms, suitable for high-precision and high real-time industrial control scenarios;

Algorithm support: Built in rich process control algorithms, including PID control, proportional control, integral control, differential control, and various custom algorithms, to meet the control needs of different processes.

(2) Communication interface parameters

Bus interface: equipped with standard industrial bus interface, supporting compatibility with Yokogawa ER bus, Vnet/IP bus, etc., to achieve high-speed data exchange with I/O modules and bus node units;

Ethernet interface: Provides multiple Ethernet interfaces, supports TCP/IP protocol, and can achieve remote communication and data sharing with upper computer, monitoring system, and other controllers;

Serial communication interface: equipped with serial interfaces such as RS-485/RS-32, supporting general industrial communication protocols such as Modbus, and can be connected to third-party intelligent instruments, sensors, and other devices;

Redundant communication support: Supports redundant configuration of communication links to ensure the continuity and reliability of critical control data transmission, avoiding system interruptions caused by single point communication failures.

(3) Power supply and power consumption parameters

Power supply voltage: Supports 24VDC DC power supply, with an allowable voltage fluctuation range of ± 10%, suitable for industrial standard power supply environment; Some models support redundant power input, further improving power supply reliability;

Power consumption parameters: adopting low-power optimization design, stable power consumption under normal working conditions, reducing the load on the power supply system, and adapting to long-term continuous operation requirements; The power consumption under redundant configuration meets the overall energy-saving standards of the system.

(4) Environmental adaptability parameters

Working temperature: -10 ℃ to 70 ℃, can adapt to temperature changes in most industrial plants, outdoor control cabinets and other different environments, ensuring calculation and control stability under extreme temperatures;

Storage temperature: -20 ℃ to 85 ℃, meeting the requirements of low and high temperature environments during storage and transportation, and avoiding component damage caused by environmental factors;

Relative humidity: 10% to 90% RH (non condensing), to prevent circuit short circuits or insulation performance degradation caused by humid environments and extend equipment service life;

Protection level: IP50, can effectively prevent dust intrusion, suitable for non outdoor scenarios installed in control cabinets, reducing the impact of dust on core components; Having excellent electromagnetic interference (EMI) suppression capability, it can resist strong interference generated by industrial field frequency converters, high-voltage equipment, etc.

(5) Physics and Extended Parameters

Installation method: Standard DIN rail installation, compatible with 35mm DIN rail, easy and secure installation, convenient for integration and deployment with other system components and later maintenance;

Dimensions: Adopting a compact design, the specific dimensions are suitable for the standardized installation space of industrial control cabinets, saving installation area inside the control cabinet and supporting dense deployment of multiple devices;

Weight: Lightweight design, with specific weight in accordance with the system rail load-bearing specifications, reducing rail load pressure and facilitating multi module combination installation;

Scalability: Supports multi module expansion, can connect multiple I/O expansion units through bus interfaces, flexibly expand I/O points, and adapt to control requirements of different scales.

Core product features

(1) High performance computing processing, fast control response

The controller is equipped with a high-performance industrial grade processor, which has high-speed logic operation and data processing capabilities. The basic instruction operation speed reaches microsecond level, and can quickly execute complex control logic and process algorithms. The minimum control cycle is as low as 10ms, which can respond in real-time to changes in on-site process parameters, issue control instructions in a timely manner, and ensure precise control of industrial production processes. The large capacity memory configuration provides sufficient support for storing complex control programs and processing large amounts of real-time data, and is suitable for large-scale, high-precision industrial control scenarios.

(2) Multi protocol compatibility, flexible communication connection

It has rich communication interfaces and multi protocol compatibility capabilities, supporting common industrial communication protocols such as Yokogawa ER bus, Vnet/IP bus, and Modbus. It can seamlessly integrate with Yokogawa's full range of I/O modules and bus node units, and is also compatible with third-party intelligent instruments, sensors, and upper computer systems. The Ethernet interface supports remote communication and data sharing, making it easy to build a centralized monitoring and management system; The design of redundant communication links ensures the continuity of critical data transmission and enhances the reliability of system communication.

(3) Redundant design optional, safe and reliable operation

Support controller redundancy and power redundancy configuration. Redundant controllers synchronize real-time operating status and control data. When the main controller fails, the backup controller can quickly switch to work without disturbance, ensuring uninterrupted control process. The redundant power input design avoids system shutdown caused by single point power supply failure, and combines excellent electromagnetic interference suppression capability and wide temperature adaptation characteristics to greatly improve the stability and safety of the controller in complex industrial environments. It is suitable for critical control links that require extremely high reliability.

(4) Flexible expansion and adaptation, easy maintenance and deployment

Adopting standardized modular design, it supports flexible expansion of I/O points and module types through bus interfaces, and can be combined into control systems of different scales according to industrial control requirements, adapting to various scenarios from small single machine control to large distributed control. The standard DIN rail installation method is convenient for on-site deployment and position adjustment, supports hot plugging (in accordance with system specifications), and allows operation and maintenance personnel to replace and maintain modules without interrupting system operation, reducing system downtime risks and improving operation and maintenance efficiency. Built in comprehensive self diagnostic function, which can monitor its own operating status in real time, quickly locate the fault point, and shorten the fault handling time.

Function and Working Principle

(1) Core functions

Core control computation: Execute preset control logic and process algorithms (such as PID control), perform real-time computation based on collected on-site process parameters, and generate accurate control instructions;

Data collection and processing: Receive on-site process parameters (such as temperature, pressure, flow) uploaded by various I/O modules through the bus interface, perform data verification, filtering, conversion and other processing, and generate usable control data and monitoring data;

Control instruction issuance: The control instructions generated by the operation are issued to the corresponding actuators or I/O output modules through the communication bus to achieve precise control of the industrial production process;

Communication interaction and data sharing: Conduct bidirectional communication with the upper computer monitoring system, other controllers, and third-party devices, upload real-time control data and device status information, receive remote monitoring instructions and parameter configuration instructions;

Redundant switching and fault diagnosis: achieving state synchronization and disturbance free switching between primary and backup controllers under redundant configuration; Real time monitoring of hardware status, communication status, and control process, diagnosing faults and triggering alarms, uploading fault codes and status information.

(2) Working principle

1. Initialization and configuration phase: After the LC82 * A industrial controller is powered on, the initialization process is automatically completed, and the preset system configuration parameters and control programs are loaded; Establish communication connections with various I/O modules and bus node units through communication interfaces to complete device identification and parameter synchronization;

2. Data acquisition stage: The controller sends data acquisition instructions to each I/O acquisition module through the bus interface, receives on-site process parameters uploaded by the module (such as temperature, pressure, liquid level, etc.), verifies and filters the collected data, removes interference signals, and ensures data accuracy;

3. Control calculation stage: The controller performs real-time calculations based on the processed process parameters and preset control logic and process algorithms (such as PID algorithm), compares the deviation between the set value and the actual collected value, and generates targeted control instructions (such as adjusting valve opening, adjusting motor speed, etc.);

4. Instruction execution and feedback stage: The controller sends the generated control instructions to the corresponding I/O output module or actuator through the communication bus, driving the actuator to act; Simultaneously receiving real-time feedback signals from actuators, verifying the execution effect of control instructions, and forming closed-loop control;

5. State monitoring and redundant maintenance stage: The controller monitors its hardware status, communication link status, and control process in real time. If a fault is detected (such as power abnormality, communication interruption, parameter exceeding threshold), an alarm is immediately triggered and fault information is uploaded; Under redundant configuration, the primary and backup controllers continuously synchronize data. When the primary controller fails, the backup controller switches without disturbance to ensure continuous and stable control process.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-