ABB LDSTA-01 (order number: 63940143B) is a high-precision and high reliability input/output (I/O) module designed for the industrial automation field. As the core data exchange unit between automation control systems and field devices, it mainly undertakes the tasks of collecting, converting, and issuing control instructions for various signals (such as analog and digital quantities) in the industrial field. This module is compatible with mainstream ABB control systems (such as AC500 PLC series, 800xA DCS system, etc.) and can seamlessly integrate into existing automation architectures. It is widely used in process industries, discrete manufacturing, energy management and other scenarios, providing accurate and real-time on-site data support for the system, ensuring the scientificity of control decisions and the efficiency of execution.

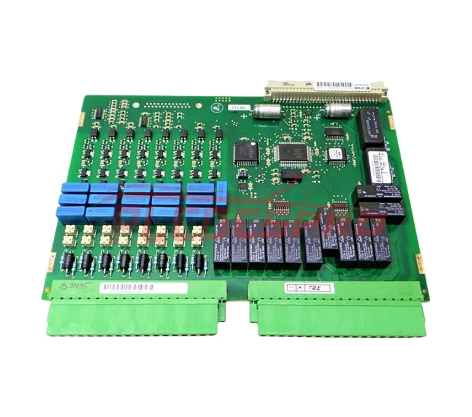

ABB LDSTA-01 63940143B Input/Output (I/O) Module

Product Overview

ABB LDSTA-01 (order number: 63940143B) is a high-precision and high reliability input/output (I/O) module designed for the industrial automation field. As the core data exchange unit between automation control systems and field devices, it mainly undertakes the tasks of collecting, converting, and issuing control instructions for various signals (such as analog and digital quantities) in the industrial field. This module is compatible with mainstream ABB control systems (such as AC500 PLC series, 800xA DCS system, etc.) and can seamlessly integrate into existing automation architectures. It is widely used in process industries, discrete manufacturing, energy management and other scenarios, providing accurate and real-time on-site data support for the system, ensuring the scientificity of control decisions and the efficiency of execution.

Its design follows strict industrial standards, with the core goal of "precise signal, stable operation, and easy integration". Through optimized circuit design and anti-interference technology, it achieves reliable processing of various on-site signals in complex industrial environments, and is a key component for improving the perception ability and control accuracy of automation systems.

Core functions and advantages

2.1 Multi type signal processing capability

The LDSTA-01 I/O module has rich signal processing functions and is compatible with multiple types of signals such as digital input/output (DI/DO) and analog input/output (AI/AO) (specific signal types are supported according to the official manual). For digital signals, it can accurately identify the on/off status of on-site equipment (such as sensor trigger signals, valve on/off status), and convert them into system recognizable digital signals; For analog signals (such as physical quantities with continuous changes in temperature, pressure, flow rate, etc.), high-precision AD/DA conversion modules can be used to convert the on-site collected analog signals into digital signals and upload them to the control unit. At the same time, the digital instructions issued by the control unit can be converted into analog signals to drive actuator actions, with a conversion accuracy of up to 0.1% FS level, meeting high-precision control requirements.

2.2 High reliability and stability

To adapt to the harsh environment of industrial sites, the module adopts a comprehensive reliability design:

-Strong anti-interference performance: Complies with IEC 61000-6-2 (industrial environment immunity) and IEC 61000-6-4 (industrial environment emission) standards, has good electromagnetic compatibility (EMC) performance, can effectively resist electromagnetic radiation and conducted interference generated by industrial field frequency converters, motors and other equipment, and avoid signal distortion or misoperation.

-Wide temperature and wide pressure adaptation: Supports a wide working temperature range of -25 ℃~70 ℃, and can adapt to extreme working conditions such as high-temperature workshops and low-temperature storage; The power supply supports 24V DC ± 15% wide range input and has overvoltage and undervoltage protection functions to avoid damage to the module caused by power fluctuations.

-Fault self diagnosis and protection: Equipped with a comprehensive fault diagnosis mechanism, it can monitor the working status of the module itself in real time (such as power failure, channel failure) and on-site signal abnormalities (such as analog signal exceeding range, digital signal jitter). When a fault occurs, it can promptly send alarm information to the control master station through the bus and mark the fault channel, making it easy to quickly locate the problem. At the same time, the output channel has a short-circuit protection function to prevent module damage caused by on-site equipment short circuits.

2.3 Flexible Integration and Expansion

The module adopts standardized modular design, supports 35mm DIN rail installation, and can be quickly combined and deployed with other I/O modules, controllers, and other devices to enhance the flexibility of the layout inside the control cabinet. In terms of system expansion, it is compatible with ABB automation system bus protocols (such as PROFINET, Modbus, etc.), and can achieve multi module cascading through bus interfaces, easily expanding the system's I/O points and meeting the needs of automation projects of different scales. In addition, the module supports the "hot plug" function (please refer to the official instructions for details), which allows for module replacement without shutting down the system, greatly reducing the impact of maintenance on production.

2.4 Convenient Debugging and Maintenance

During the debugging process, ABB specialized programming software (such as CODESYS, Control Builder M) can be used to configure module parameters, including signal type, range, filtering time, alarm threshold, etc. The software interface is intuitive and easy to understand, and supports online monitoring of real-time data and status of each channel. The module panel is equipped with LED indicator lights, which can intuitively display the power status, bus communication status, and the working status of each channel (such as input/output validity, faults, etc.). On site maintenance personnel can quickly judge the operation status of the module without the need for professional equipment, improving maintenance efficiency.

2.5 Long term stable lifecycle support

As a member of ABB's industrial control product family, the LDSTA-01 module has a long product lifecycle and comprehensive technical support services. ABB provides continuous firmware upgrade services for this module, which can optimize module performance and expand functionality through software updates to meet the constantly evolving automation control requirements; At the same time, ABB's global service network can provide users with timely technical consultation, troubleshooting, and maintenance services, ensuring the long-term stable operation of equipment.

Key technical parameters

Order Number

63940143B

Product Model

LDSTA-01

signal type

Digital input/output (DI/DO), analog input/output (AI/AO)

Analog input accuracy

± 0.1% FS (typical value)

Digital input response time

≤ 1ms (configurable)

Digital output driving capability

Maximum 2A/channel (DC output)

power supply

24V DC ±15%

Working temperature range

-25℃ ~ 70℃

Storage temperature range

-40℃ ~ 85℃

Protection level

IP20 (Panel Installation)

Installation method

35mm DIN rail installation

communication interface

Supports industrial buses such as PROFINET and Modbus

Electromagnetic compatibility standards

IEC 61000-6-2, IEC 61000-6-4

Applicable scenarios

1. Process industry process control: In industries such as chemical, petroleum, and pharmaceutical, it is used to collect analog signals such as temperature, pressure, and liquid level of reaction vessels, as well as digital signals of valve and pump switch status, and issue control instructions to actuators to achieve precise control of the production process.

2. Discrete manufacturing equipment control: In automotive assembly and mechanical processing production lines, various sensors (such as photoelectric sensors, proximity switches) and actuators (such as cylinders, motors) are connected to achieve real-time monitoring and action control of equipment operation status, ensuring continuous and stable operation of the production line.

3. Energy management system: In energy monitoring scenarios of power plants, substations, and industrial enterprises, it collects electrical parameter signals such as voltage, current, and power, as well as flow signals of energy media such as water, gas, and steam, to provide data support for energy consumption statistics and optimized scheduling.

4. Environmental monitoring and security system: In industrial plant environmental monitoring, signals such as temperature and humidity, dust concentration, and gas concentration are collected; In security scenarios, connecting devices such as infrared detectors and access switches enables rapid response and alarm of abnormal signals.

5. Intelligent upgrade of old equipment: Install this I/O module on traditional industrial equipment to collect and remotely control equipment operation data, improve the intelligence level of old equipment, and reduce upgrade and renovation costs.

Precautions for use

-Before installing the module, it is necessary to confirm that the on-site environmental conditions (temperature, humidity, electromagnetic interference) meet the requirements for product use, and avoid installation and use in environments that exceed specifications.

-When wiring, it is necessary to strictly follow the module terminal definition for connection, distinguish the positive and negative poles of the power supply, input/output signal lines, and avoid reverse connection or short circuit; Analog signal cables should use shielded twisted pair cables, with the shielding layer reliably grounded at one end to reduce signal interference.

-When configuring parameters, it is necessary to accurately set them according to the type and range of the on-site signal, such as the signal range of analog input (4-20mA, 0-10V, etc.), the filtering time of digital input, etc., to ensure that the parameters match the on-site equipment.

-During the operation of the module, regularly check whether the wiring terminals are loose, whether the LED indicator light status is normal, clean the dust inside the module and control cabinet, and maintain good ventilation and heat dissipation conditions.

-Before replacing or maintaining the module, it is necessary to cut off the power supply of the module. If the system supports hot plugging, it is necessary to strictly follow the official operating procedures to avoid damage to the module or system caused by live operation.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-