ABB CRBX01 (order number: 2VAA008424R1) is a high-performance remote bus extender designed specifically for industrial automation systems. It is mainly used to solve the problems of limited transmission distance, insufficient number of nodes, and stable signal transmission in complex environments of industrial fieldbus. As an important component of ABB's automation control system, this product can seamlessly connect with mainstream industrial bus protocols, enabling high-speed data exchange between control units, remote I/O modules, and intelligent devices. It is widely used in industries such as automotive manufacturing, metallurgy, chemical engineering, and power that require high control accuracy and system stability.

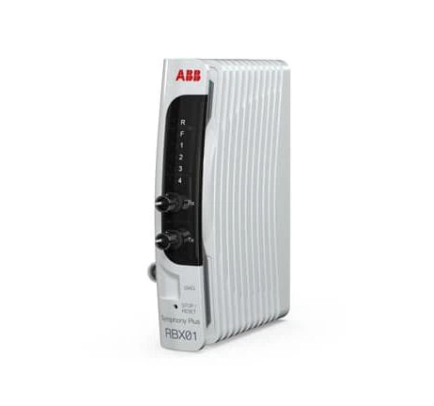

ABB CRBX01 2VAA008424R1 Remote Bus Expander

Product Overview

ABB CRBX01 (order number: 2VAA008424R1) is a high-performance remote bus extender designed specifically for industrial automation systems. It is mainly used to solve the problems of limited transmission distance, insufficient number of nodes, and stable signal transmission in complex environments of industrial fieldbus. As an important component of ABB's automation control system, this product can seamlessly connect with mainstream industrial bus protocols, enabling high-speed data exchange between control units, remote I/O modules, and intelligent devices. It is widely used in industries such as automotive manufacturing, metallurgy, chemical engineering, and power that require high control accuracy and system stability.

Its core design philosophy is guided by "reliable expansion, efficient transmission, and convenient integration", adopting industrial grade hardware architecture and anti-interference technology, which can adapt to harsh industrial environments and provide solid guarantees for the flexible deployment and efficient operation of automation systems.

Core functions and advantages

2.1 Flexible bus expansion capability

This remote bus extender supports multiple mainstream industrial bus protocols (such as PROFINET, EtherNet/IP, Modbus TCP, etc., specific protocol support needs to be combined with actual configuration), and can remotely extend the bus interface of the control master station, breaking the physical distance limitation of traditional bus transmission. For example, in a large production workshop, when the distance between the control cabinet and the on-site equipment exceeds the bus standard transmission distance, CRBX01 can achieve long-distance signal transmission through optical fiber or shielded twisted pair, with a maximum transmission distance of several kilometers (the specific distance depends on the transmission medium and protocol type).

At the same time, it can expand multiple bus nodes, allowing access to a large number of I/O modules, sensors, actuators, and other intelligent devices at remote sites, effectively solving the problem of insufficient number of single bus nodes and improving the scalability and deployment flexibility of the system.

2.2 High speed and stable data transmission

CRBX01 adopts a high-speed data processing chip that supports real-time data transmission. The data transmission rate is consistent with the main station bus rate, ensuring seamless interaction between control instructions and on-site feedback signals, meeting the strict requirements of industrial automation systems for real-time performance. In the scenario of concurrent communication among multiple devices, the product has excellent data flow management capabilities, which can avoid data congestion and packet loss, and ensure the accuracy of system control.

2.3 Industrial grade reliability design

In response to the complex environment of industrial sites, this product has undergone comprehensive reliability optimization:

-Anti interference performance: It has strong electromagnetic interference (EMI) protection capability, complies with the IEC 61000 series industrial electromagnetic compatibility standards, and can effectively resist electromagnetic radiation interference generated by frequency converters, motors and other equipment, ensuring stable signal transmission.

-Wide temperature working range: Supports a wide temperature working environment of -20 ℃~60 ℃, can adapt to extreme working conditions such as high and low temperatures, and does not require additional temperature control equipment.

-Sturdy structure: Designed with a metal shell, it has good dust, moisture, and earthquake resistance performance, with a protection level of up to IP20 (panel installation) or higher (specific to the product manual), suitable for installation in control cabinets or harsh environments in industrial sites.

2.4 Convenient Installation and Debugging

The product adopts a standardized guide rail installation method, which can be quickly integrated into existing industrial control cabinets, and the installation process is simple and efficient. In terms of debugging, it supports parameter configuration through ABB dedicated configuration software or mainstream industrial control software, with intuitive fault diagnosis function. It can monitor the bus communication status and equipment operation status in real time. When communication interruption, module failure and other problems occur, it can timely send alarm signals and display fault codes, greatly reducing the difficulty of on-site debugging and maintenance.

2.5 Seamless System Integration

As a member of ABB's automation product ecosystem, CRBX01 can seamlessly integrate with mainstream control equipment such as ABB AC500 series PLC and 800xA DCS system, without the need for complex protocol conversion configuration, reducing the workload and compatibility risks of system integration. At the same time, its open interface design also supports compatibility with other brands of industrial control equipment, enhancing the product's applicability.

Key technical parameters

Order Number

2VAA008424R1

Product Model

CRBX01

Support bus protocol

PROFINET IO, EtherNet/IP, Modbus TCP, etc

transmission rate

10/100 Mbps adaptive (Ethernet)

Expand the number of nodes

Depending on the bus protocol, up to 64 nodes are supported (example value)

power supply

24V DC ±10%

Working temperature range

-20℃ ~ 60℃

Storage temperature range

-40℃ ~ 85℃

Protection level

IP20 (Panel Installation)

Installation method

35mm DIN rail installation

Electromagnetic compatibility standards

IEC 61000-6-2, IEC 61000-6-4

Applicable scenarios

1. Interconnection of large-scale industrial plant equipment: In large-scale scenarios such as automotive welding production lines and metallurgical rolling workshops, connecting equipment scattered in different areas to achieve centralized control of the entire workshop equipment by the control master station.

2. Signal extension in harsh environments: In places with harsh environments such as chemical parks and mines, control signals are extended from the control room to on-site equipment to avoid interference from the environment on signal transmission.

3. Upgrading and renovating old systems: Expanding bus nodes for traditional automation systems, improving the control range and intelligence level of the system, and reducing upgrade costs.

4. Building a distributed control system: In a distributed control system, as a regional bus hub, it connects all intelligent devices in the area to achieve centralized data collection and instruction issuance within the area.

Precautions for use

-Before installation, it is necessary to confirm that the product's power supply voltage matches the on-site power supply to avoid equipment damage caused by overvoltage or undervoltage.

-When wiring, the bus cable and power cable should be laid separately to reduce electromagnetic interference; If using twisted pair transmission, it is necessary to ensure that the cable shielding layer is reliably grounded.

-When configuring parameters, it is necessary to strictly follow the requirements of the system bus protocol to ensure that the communication parameters with the master and slave devices are consistent.

-Regularly maintain and inspect the equipment, clean the dust on the casing, check if the wiring terminals are loose, and ensure stable operation of the equipment.

-If it is necessary to replace the equipment, the configuration parameters of the original equipment should be recorded, and the replacement should be carried out after the new equipment is configured to avoid affecting the normal operation of the system.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-