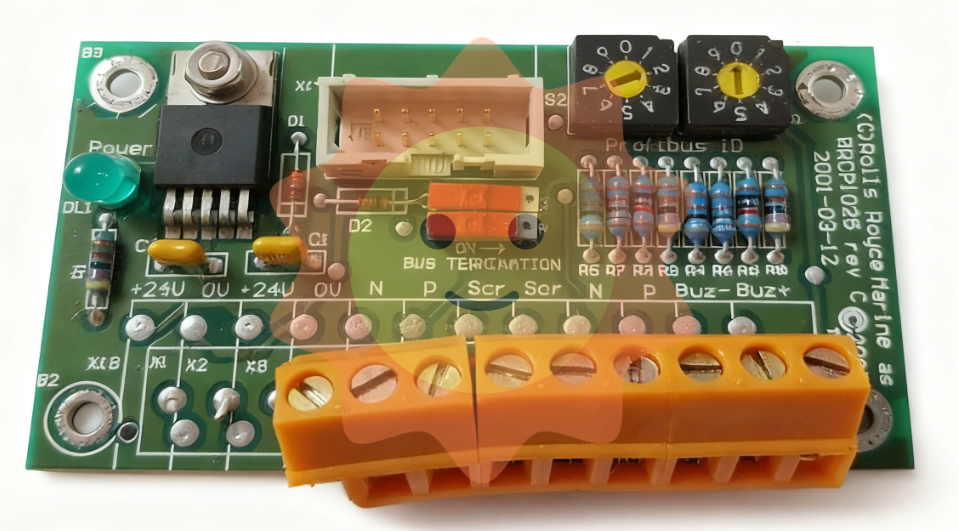

Rolls-Royce MPC-200/MPC220 - Aquamaster Rauma aquamaster Oy Ab Ver. 1.13KC

The Rolls-Royce MPC-200/MPC220 stands as a pinnacle of advanced control technology within the Rolls-Royce automation products lineup, specifically engineered for demanding environments in the power industry, petrochemical sector, and general automation applications. Renowned for its robust design and exceptional performance, the MPC-200/MPC220 offers a versatile and reliable solution that meets the high standards of industrial automation and control systems. At its core, the Rolls-Royce MPC-200/MPC220 features a high-capacity input/output (I/O) system capable of handling extensive signal processing requirements. With support for multiple analog and digital inputs and outputs, the unit facilitates seamless integration with a wide range of sensors, actuators, and control devices. Its I/O architecture ensures rapid response times and precise signal handling, critical for applications where timing and accuracy are paramount. The MPC-200/MPC220 boasts a modular design enhancing scalability and ease of maintenance, while its rugged construction guarantees durability even under harsh industrial conditions, including extreme temperatures, humidity, and vibration. Performance metrics for the MPC-200/MPC220 highlight its superior processing speed combined with advanced diagnostics and fault-tolerant features. This ensures continuous operation and minimizes downtime in critical processes such as power generation and petrochemical refining.

The device supports advanced communication protocols for seamless integration within complex automation networks, facilitating real-time data exchange and remote monitoring capabilities. Real-world applications of the Rolls-Royce MPC-200/MPC220 demonstrate its versatility and reliability. In the power industry, it excels in managing turbine control systems, power distribution automation, and safety interlocks, ensuring optimal efficiency and operational safety. In petrochemical plants, the MPC-200/MPC220 is instrumental in controlling process variables, managing emergency shutdown systems, and automating critical refining processes. Additionally, its adaptability makes it a preferred choice for general automation tasks, including factory floor automation, conveyor systems, and environmental control systems. When compared to other Rolls-Royce models such as the Rolls-Royce PCC1030C and Rolls-Royce TDI-11, the MPC-200/MPC220 stands out for its enhanced input/output capacity and superior processing speed. While the PCC1030C offers excellent control capabilities primarily for marine applications, and the TDI-11 focuses on diagnostic functions, the MPC-200/MPC220 combines these strengths with increased scalability and ruggedness suited for industrial automation.

Unlike the Rolls-Royce GWY 01 or Rolls-Royce PFP-01 models, which are optimized for specialized control tasks, the MPC-200/MPC220 provides a more comprehensive control solution with broader application flexibility. Alongside the Rolls-Royce MPC-200/MPC220, we also offer complementary models such as the Rolls-Royce UMAS-V and Rolls-Royce UN 926, which provide additional functionalities for remote monitoring and supervisory control. The Rolls-Royce 5801-CS-IFC-01 and Rolls-Royce 5880-PC1020 Rev.C further extend system capabilities by offering specialized interface and communication options. For applications requiring advanced thruster control and marine automation, the Rolls-Royce Bow Thruster Controller and Rolls-Royce Lilaas Azimuth LF70L-01-09 complement the MPC-200/MPC220’s automation capabilities, ensuring seamless integration across diverse operational environments. Moreover, the Rolls-Royce HELICON-X-MP and Rolls-Royce Sistema De Control Remoto provide additional layers of control and remote operational capacity, enhancing the overall system’s robustness. The integration of these models with the MPC-200/MPC220 ensures a holistic automation ecosystem capable of addressing complex challenges in power generation, petrochemical processing, and general industrial automation.

The application of MPC-200/MPC220 in power industry, petrochemical, and general automation is a testament to its design excellence and operational reliability. Its ability to handle complex control tasks, provide real-time data processing, and ensure system resilience under demanding conditions makes it an indispensable asset for engineers and operators aiming for maximum efficiency and safety. In summary, the Rolls-Royce MPC-200/MPC220 distinguishes itself through its superior I/O capacity, durability, and performance metrics tailored for the power industry, petrochemical, and general automation sectors. When integrated with other Rolls-Royce automation products such as the Rolls-Royce 5880-PC1019 Rev. B, Rolls-Royce UN 975, and Rolls-Royce CCM-FPGI, it forms part of a comprehensive suite designed to meet the evolving needs of modern industrial automation. Its proven track record and seamless compatibility with complementary Rolls-Royce models ensure that the MPC-200/MPC220 remains a leading choice for mission-critical automation applications worldwide.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-