NF93A-2 (NF stands for Networked Field Controller); 93 "indicates the level of control performance and scalability; A "is the hardware version, which has optimized the computational efficiency; '2' represents dual communication port redundancy), order numbers HESG440280R2 (main controller unit), HESG323662R1 (communication expansion card), HESG216665/K (power supply and installation accessories package), compatible with ABB AC 800M, Advant OCS, and third-party mainstream control systems.

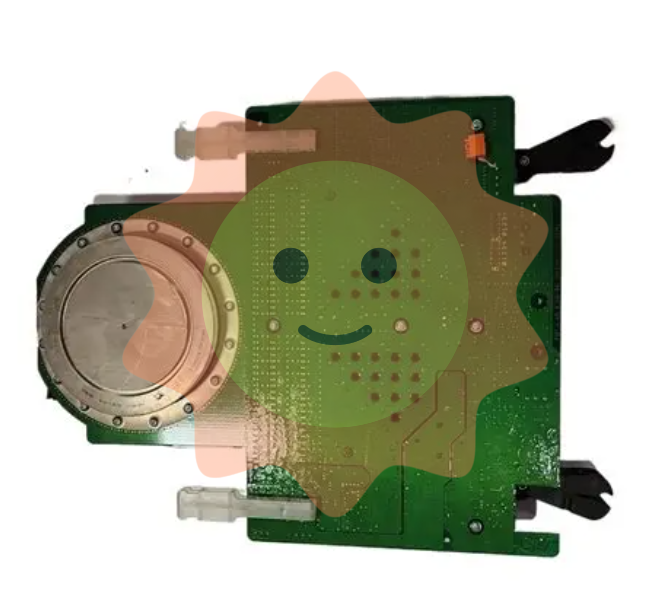

ABB NF93A-2 HESG440280R2 HESG323662R1/HESG216665/K Module Controller

Core attributes and identification

Product type: Distributed module controller (belonging to ABB Advant Fieldbus series, focusing on industrial field distributed control, with local logic operation, signal preprocessing and collaborative control capabilities, suitable for the decentralized control node requirements of large DCS/PLC systems, can independently complete small-scale equipment control or serve as an extension node of the main controller)

Model decoding: NF93A-2 (NF stands for Networked Field Controller); 93 "indicates the level of control performance and scalability; A "is the hardware version, which has optimized the computational efficiency; '2' represents dual communication port redundancy), order numbers HESG440280R2 (main controller unit), HESG323662R1 (communication expansion card), HESG216665/K (power supply and installation accessories package), compatible with ABB AC 800M, Advant OCS, and third-party mainstream control systems.

Physical specifications: Adopting a dual installation design of guide rail and wall mounted, with dimensions of 155mm (width) x 230mm (height) x 90mm (depth), net weight of 2.1kg, metal shell integrated heat dissipation structure, suitable for installation in industrial distribution boxes or control cabinets, and can be directly deployed in areas close to controlled equipment to reduce control command transmission delay.

Key technical parameters

Control performance

32-bit ARM Cortex-A8 processor, with a main frequency of 800MHz, a processing speed of 800 MIPS, and support for floating-point operations; Program storage 64MB Flash (expandable to 256MB), data storage 32MB DDR3 RAM (supports ECC verification)

Capable of independently running 128 control circuits and processing 512 I/O data, meeting the needs of small and medium-sized distributed control, such as local equipment linkage control in workshop production lines

I/O expansion capability

Built in 4-channel AI (4-20mA/0-10V, 16 bit resolution), 2-channel AO (4-20mA, 12 bit accuracy), 8-channel DI (24V DC, optoelectronic isolation), and 4-channel DO (24V DC/3A, relay output); Supports connecting 8 I/O submodules (such as AI submodule and DO submodule) through expansion interfaces, with a maximum expansion of 256 I/O channels

Basic I/O meets small-scale control requirements, with the ability to expand and adapt to medium to large distributed scenarios. Channels can be flexibly added or removed according to on-site needs to avoid resource waste

Communication capability

2 Gigabit Ethernet interfaces (supporting Modbus TCP, Profinet IRT, EtherNet/IP), 2 Profibus DP master/slave interfaces (supporting DPV1 protocol, adaptive speed of 1.5-12Mbps), 1 RS485 backup interface (supporting Modbus RTU)

Multi protocol+redundant communication design, Gigabit Ethernet for high-speed data exchange (latency ≤ 2ms), dual Profibus DP to ensure fieldbus reliability, suitable for complex industrial network architectures

Power supply demand

DC 24V ± 15%, rated power consumption of 22W, maximum power consumption of 30W (when expanding I/O at full load)

It can be centrally powered by ABB SR511 power module or independently powered by on-site distribution box, with wide voltage input to adapt to voltage fluctuations in industrial sites, and supports redundant power supply access (requires accessory package)

Working environment

Temperature -35 ℃ to+75 ℃, humidity 5% -95% (no condensation, supports short-term condensation), protection level IP65 (enclosure), IP20 (expansion interface)

Strong adaptability to extreme environments, can be deployed outdoors (such as wind turbine tower control boxes), in high-temperature workshops (such as steel rolling areas), and in high humidity areas (such as paper mills). The shell resists dust, rainwater, and corrosive gases

Security and Certification

Compliant with IEC 61508 SIL 2 standard, anti electromagnetic interference level IEC 61000-6-2 (level 4+), CE, UL, ATEX certification

Meets industrial safety control requirements and can be used in chemical explosion-proof areas (ATEX certification covers Zone 2), with anti-interference ability suitable for strong electromagnetic environments with dense frequency converters and high-voltage motors

Core functions and technological advantages

1. Distributed control and collaborative computing

Local independent control capability: without relying on the main controller (such as PM861K01), it can independently operate control logic, such as the start stop sequence of equipment at a certain workstation of the production line, temperature regulation, etc., reducing the computational load of the main controller; When communication with the main controller is interrupted, it automatically switches to "local independent mode" to maintain the operation of critical equipment, synchronizes data after communication is restored, and avoids production interruptions.

Data pre-processing and edge computing: support local pre-processing of the collected I/O data (such as filtering, range conversion, outlier elimination), and only upload the effective data to the main controller or cloud platform to reduce the occupation of network bandwidth; The built-in edge computing function can run simple analysis algorithms (such as equipment operation status evaluation, energy consumption statistics), and output real-time warning information, such as triggering local alarm when the motor current is abnormal.

Multi device collaborative linkage: Connect peripheral I/O modules (such as IW93-2), actuators (such as regulating valves), and sensors through Profibus DP or Ethernet interfaces to achieve multi device collaborative control. For example, in logistics sorting lines, NF93A-2 receives cargo detection signals collected by IW93-2, controls the linkage between sorting robotic arms and conveyor belts, with a response time of ≤ 5ms, ensuring sorting accuracy and efficiency.

2. High reliability and redundancy guarantee

Full dimensional redundancy design: supports communication redundancy (dual Ethernet+dual Profibus DP, switching time ≤ 10ms), power redundancy (dual 24V input, automatic switching), I/O redundancy (extended I/O module supports dual module hot standby), core control loop MTBF (mean time between failures) exceeding 80000 hours, suitable for industrial scenarios with high continuity requirements (such as petrochemical continuous production facilities).

Fault self diagnosis and localization: It has triple diagnostic functions at the module level, channel level, and communication link level, which can monitor CPU status, power supply voltage, I/O channel signals, and communication link quality in real time. Fault information is uploaded through local LED indicator lights (red/green/yellow status lights) and remote communication, supporting accurate fault localization to "short circuit of a certain DI channel". Operation and maintenance personnel do not need to investigate one by one on site, shortening the fault handling time.

Anti extreme environmental capability: using wide temperature industrial grade components (working temperature -40 ℃ to+125 ℃) and conformal coating three proof coating process (moisture-proof, anti salt spray, anti-corrosion), it can operate for a long time in harsh environments such as offshore platforms (high salt spray), underground mines (high dust), polar scientific research stations (extreme low temperature), etc; The IP65 protection of the casing can withstand short-term rain and is suitable for outdoor temporary control needs.

3. Flexible scalability and ease of use

Modular extension architecture: AI, AO, DI, and DO sub modules can be flexibly added through standard extension interfaces without downtime during the extension process. It supports "plug and play" and automatically identifies and configures modules; Support the integration of third-party standard I/O modules (compliant with Profibus DP or Modbus protocols) to reduce system upgrade costs and adapt to industrial scenarios with mixed brand devices.

Convenient programming and debugging: compatible with ABB Control Builder software and IEC 61131-3 standard programming languages (ladder diagram LD, function block diagram FBD, structured text ST, etc.), the software has built-in commonly used control templates (such as PID adjustment, sequential control), and drag and drop programming reduces the operating threshold; Support remote debugging, operation and maintenance personnel can access the module's web management interface through Ethernet interface, monitor data in real time, modify parameters without on-site operation.

Local visualization and operation: The front of the module is equipped with a 2.4-inch LCD display screen (displaying I/O data, fault information, and operating mode) and four physical buttons (manual/automatic switching, parameter setting, fault reset, emergency stop). Operations personnel can locally view the operating status, modify basic parameters, and in emergency situations, cut off dangerous outputs through the "emergency stop" button to ensure equipment and personnel safety.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-