NP1BS-06/08, as the main model launched by Fuji for the small automation market, is positioned as "streamlined, efficient, and easy to deploy". Compared with high-end modules in the same series, it simplifies redundant functions through integrated design while maintaining core control performance, effectively reducing product costs and volume; At the same time, it has good compatibility and scalability, and can flexibly adapt to the control needs of different scenarios. It is suitable for independent control of single machine devices and can also be used as an auxiliary control unit for large systems to achieve precise local control.

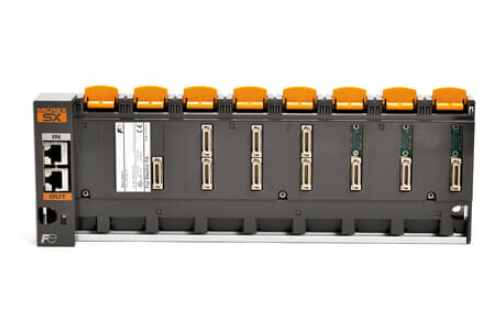

FUJI NP1BS-06/08 Programmable Controller

Core positioning and advantages of the product

NP1BS-06/08, as the main model launched by Fuji for the small automation market, is positioned as "streamlined, efficient, and easy to deploy". Compared with high-end modules in the same series, it simplifies redundant functions through integrated design while maintaining core control performance, effectively reducing product costs and volume; At the same time, it has good compatibility and scalability, and can flexibly adapt to the control needs of different scenarios. It is suitable for independent control of single machine devices and can also be used as an auxiliary control unit for large systems to achieve precise local control.

Key technical characteristics

1. Compact integrated design, saving installation space

The controller adopts an integrated compact structure, which highly integrates the CPU, power supply, input/output interface and other core components into a single module, without additional rack configuration, and greatly reduces the installation volume (usually only a few centimeters thick, and the details are subject to the product manual). Its design complies with industrial standard installation specifications, supports quick installation with guide rails, and can be directly embedded in narrow spaces of equipment control cabinets, effectively saving equipment layout space and reducing control cabinet design costs.

2. Stable and reliable input-output control

NP1BS-06/08 optimized the input-output circuit design for the control requirements of small devices. Among them, NP1BS-06 is equipped with 3 inputs and 3 outputs, and NP1BS-08 is equipped with 4 inputs and 4 outputs, both of which support digital signal processing and can directly connect peripheral devices such as sensors, buttons, indicator lights, and small contactors. The input circuit has signal filtering function, which can effectively suppress on-site interference signals and ensure the stability of the input signal; The output circuit adopts reliable switching elements and has overcurrent protection function, which can avoid damage to the controller caused by abnormal load and improve the safety of system operation.

3. Wide environmental adaptability, suitable for complex scenes

Continuing the industrial design standards of the NP1 series, NP1BS-06/08 has excellent environmental adaptability. Its working temperature range covers 0 ℃ -55 ℃, which can adapt to the temperature environment of most industrial workshops and equipment rooms; At the same time, it has strong anti vibration and anti impact performance, complies with relevant IEC standards, and can resist the mechanical vibration effects generated during equipment operation. In addition, the controller adopts an isolation design internally, where the input and output circuits are isolated from the power supply circuit, effectively enhancing its ability to resist electromagnetic interference and ensuring stable operation near interference sources such as motors and frequency converters.

4. Convenient programming and maintenance, reducing the threshold for use

This controller is compatible with specialized programming software such as Fuji FLEX PC Programmer and supports ladder diagram (LD), the most commonly used programming method in the industrial field. The interface is simple and intuitive, making it easy for even junior engineers to quickly get started. The software has a built-in basic instruction library, covering common logic control instructions such as contact control, coil drive, timer, counter, etc., which can meet the programming needs of the vast majority of small control scenarios. At the same time, the software supports online monitoring and fault diagnosis functions, which can display real-time input and output status, program running trajectory, and quickly locate the fault point when the system fails, greatly reducing maintenance time.

5. Flexible scalability to meet upgrade requirements

Although NP1BS-06/08 has a compact design, it still retains some expandability. Some models are equipped with standard communication interfaces (such as RS-485), which can achieve data exchange with upper computer, touch screen and other devices, and support remote monitoring and parameter setting; At the same time, through dedicated expansion interfaces, a small number of special functional modules of the same series (such as analog input/output modules) can be externally connected according to actual needs, to achieve the acquisition and control of analog signals such as temperature and pressure, meet the upgrading of control requirements, and enhance the product lifecycle value.

Main technical parameters (reference standard specifications)

parameter category

NP1BS-06 specification

NP1BS-08 specification

Instructions

Power Specifications

DC 24V ±10%

DC 24V ±10%

Industrial standard DC power supply, compatible with common equipment power supply systems

Input points

3 points (numerical quantity)

4 points (numerical quantity)

Support NPC/PNP sensor input, input signal voltage DC 24V

Input response time

≤10ms

≤10ms

Quickly respond to external signals to ensure real-time control

Output points

3 points (relay)

4 o'clock (relay)

Relay output with mechanical contact isolation function

Output load capacity

AC 250V/2A,DC 30V/2A

AC 250V/2A,DC 30V/2A

Single output can directly drive small industrial loads

Program capacity

1k steps

1k steps

Meet the storage requirements of small control logic programs

Communication interface (optional)

RS-485

RS-485

Support common communication protocols such as Modbus to achieve data exchange

Protection level

IP20 (front)

IP20 (front)

Suitable for installation inside control cabinets to prevent fingers from touching live parts

Typical application scenarios

1. Control of small mechanical equipment: widely used in small packaging machines, sealing machines, labeling machines and other equipment to achieve functions such as start stop control, process timing, counting statistics, fault alarm, etc., replacing traditional relay control systems and improving equipment control accuracy and flexibility.

2. Automation unit monitoring: Responsible for collecting signals from photoelectric sensors, position switches, etc. in scenarios such as single workstations on assembly lines and storage rack access units, controlling the actions of actuators such as cylinders and conveyor belts, and achieving automation control of local processes.

3. Control of civilian and commercial equipment: Suitable for vending machines, parking lot barriers, small central air conditioning units and other equipment, realizing automatic operation and status switching based on signal triggering, improving the intelligence and operational efficiency of equipment.

4. Teaching and practical training scenarios: Due to its small size, low cost, and easy operation, it is often used as a PLC teaching and training equipment in vocational colleges to help students quickly master PLC programming and control principles.

Installation and usage precautions

-When installing, it is necessary to choose a dry and ventilated environment, avoid installing in places with humidity greater than 90% (no condensation), dense dust or corrosive gases, and prevent damage to the internal components of the controller.

-Before wiring, the power must be cut off, and the wiring of input and output circuits must be strictly in accordance with the product manual markings to avoid reverse polarity or short circuits; The wiring terminals need to be tightened to prevent signal abnormalities or heating caused by poor contact.

-The power lines of controllers and high-power devices (such as motors and heaters) should be wired separately to avoid parallel installation and reduce electromagnetic interference; If it is necessary to install near the interference source, it is recommended to take shielding measures.

-When programming, the principle of clear logic should be followed to avoid redundant instructions; After the program is written, it needs to undergo offline simulation testing to confirm the logic is correct before downloading to the controller. During the first run, it needs to be gradually debugged to observe whether the device action meets expectations.

-Regularly inspect the controller, clean the surface dust, check whether the wiring terminals are loose, and whether the indicator lights are normal; If left idle for a long time, it should be stored in a dry, room temperature environment and avoid direct sunlight.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-