YOKOGAWA NP53 * C is a high-performance precision control module launched by YOKOGAWA Electric Corporation in Japan. It features high resolution, high-speed response, and high input accuracy, designed specifically for precise control of key parameters such as temperature, pressure, and flow in industrial scenarios. This module adopts a compact structure (48 × 48mm), integrating multiple functions such as universal sensor input, flexible output control, and preventive maintenance. It can adapt to various industrial sensors and is widely used in automated production lines that require strict parameter control. With stable control performance and convenient operation design, it provides core support for precise control of industrial processes. Its origin is Japan, and it follows strict industrial grade quality standards to ensure long-term reliable operation in complex industrial environments.

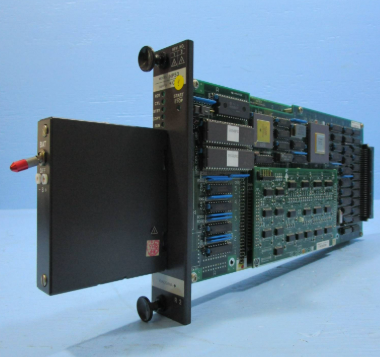

YOKOGAWA NP53 * C Precision Control Module

Product Overview

YOKOGAWA NP53 * C is a high-performance precision control module launched by YOKOGAWA Electric Corporation in Japan. It features high resolution, high-speed response, and high input accuracy, designed specifically for precise control of key parameters such as temperature, pressure, and flow in industrial scenarios. This module adopts a compact structure (48 × 48mm), integrating multiple functions such as universal sensor input, flexible output control, and preventive maintenance. It can adapt to various industrial sensors and is widely used in automated production lines that require strict parameter control. With stable control performance and convenient operation design, it provides core support for precise control of industrial processes. Its origin is Japan, and it follows strict industrial grade quality standards to ensure long-term reliable operation in complex industrial environments.

Core functional features

1. High precision measurement and high-speed response

The module has excellent measurement accuracy, with thermocouple/platinum resistance (PT) input accuracy of ± 0.1% of the measured value (PV) and analog input accuracy of ± 0.1% of the full range (FS), ensuring the accuracy of parameter measurement. Simultaneously adopting a high-speed sampling period design with a sampling frequency as low as 60ms, it can quickly capture changes in on-site parameters, adjust control strategies in a timely manner, and avoid control deviations caused by response delays. It is suitable for precision control scenarios that are sensitive to parameter fluctuations.

2. Universal sensor input design

All models support universal input functions and are compatible with thermocouples, platinum resistors (PT), and analog signals (current/voltage). They can adapt to different types of field sensors without the need to replace modules, greatly improving the universality and application flexibility of the product, reducing the difficulty of system selection and spare parts inventory costs, and easily meeting diverse industrial parameter measurement needs.

3. Flexible output control and logical operation capability

The module is equipped with two sets of auxiliary output channels, supporting various forms of output such as relay output, voltage output (used to drive solid-state relays SSR), current output, and linear voltage output, which can accurately drive on-site actuators. Through the supporting software (CX Thermo Ver. 4.0), the output signal can be subjected to "AND/OR" logical operations and delay settings to meet the linkage requirements in complex control scenarios.

4. Rich status monitoring and alarm functions

Equipped with PV/SV status automatic switching display function, it can automatically switch display between measured value (PV), set value (SV) and controller operating status (automatic/manual, running/stop, alarm information), intuitively presenting the equipment operating status. At the same time, it integrates multiple alarm functions, including heater burnout alarm, solid-state relay (SSR) fault alarm, heater overcurrent alarm, and PV change rate alarm, which can timely detect equipment abnormalities and trigger warnings to ensure the safe operation of the system.

5. Preventive maintenance and communication expansion capability

Built in control output on/off counter, which can count the running times of relays in the temperature controller, providing data support for preventive maintenance of equipment and extending its service life. Some models support RS-485 or RS-232C communication interfaces for easy access to industrial communication networks, enabling remote monitoring and centralized management.

Detailed technical specifications

1. Input parameters

-Input type: Universal input (thermocouple, platinum resistance PT, analog current/voltage)

-Measurement accuracy: thermocouple/PT input ± 0.1% PV; analog input ± 0.1% FS

-Sampling period: 60ms high-speed sampling

-Heater current detection: supports single/three-phase heater detection, maximum detection current 50A AC, detection range 0.1~49.9A (accuracy ± 5% FS ± 1 bit)

2. Output parameters

-Output channel: 2 sets of auxiliary outputs

-Output types: relay output, voltage output (driving SSR), current output, linear voltage output

-Alarm detection response: The minimum detection on/off time is 100ms for both

3. Electrical protection parameters

-Insulation strength: 1000V AC, lasting for 1 minute

-Anti vibration performance: 50Hz, 98m/s ²

4. Environmental and physical parameters

-Working environment temperature: 0 ℃~40 ℃, suitable for conventional workshop and control room environments

-Working humidity: 25%~80% RH (non condensing), avoid humid, corrosive gases, dust, salt spray, and oil fume environments

-Storage environment: Temperature -25 ℃~75 ℃, humidity 0~85% RH (no condensation), no severe impact or vibration

-Dimensions: 48 × 48mm Compact design

-Accessory weight: E54-CT1 about 11.5g; E54-CT3 about 50g (including 2 armatures and 2 plugs)

Applicable system and configuration requirements

The YOKOGAWA NP53 * C precision control module can be integrated into industrial automation systems as an independent control unit, or linked with PLC and DCS systems through communication interfaces. When configuring, the following points should be noted:

-Software configuration: The matching CX Thermo Ver.4.0 software is required to perform logical operations, set delay parameters, and communication parameters to ensure that the parameter configuration matches the control requirements

-Wiring specifications: Control circuits must maintain a minimum distance of 100mm from the main circuit and power cables to avoid electromagnetic interference; It is recommended to use shielded wires for signal cables, with the shielding layer grounded at a single point on the signal receiving side

-Current Transformer (CT) Connection: When used in conjunction with a CT, it is necessary to correctly connect it to the secondary side of the CT; Before disconnecting the instrument, the CT secondary side must be short circuited to avoid high voltage on the secondary side that may cause electric shock or equipment damage

-Grounding requirements: The module must implement standardized grounding, and the grounding resistance must meet the system requirements to ensure anti-interference performance and personnel safety

Typical application scenarios

With high-precision control, flexible adaptation, and rich protection functions, the NP53 * C module is widely used in industrial fields that require high parameter control accuracy. Typical scenarios include:

1. Precision manufacturing industry

Suitable for precise temperature control in electronic component manufacturing, semiconductor processing, precision machining and other scenarios, it can real-time regulate the temperature parameters of heating furnaces, incubators, reaction chambers and other equipment, and with the help of heater fault alarm function, ensure the stability of product processing quality.

2. Chemical and pharmaceutical industries

In chemical reaction processes, pharmaceutical production, and other scenarios, the temperature and pressure parameters of the reaction kettle can be accurately controlled, and equipment abnormalities can be detected in a timely manner through various alarm functions to avoid product quality problems or safety accidents caused by parameter fluctuations and ensure the compliance of the production process.

3. Food processing and packaging industry

Used for temperature control in food baking, sterilization, refrigeration and preservation processes, such as oven temperature regulation and cold chain storage temperature monitoring. Through high-precision measurement and stable control, it ensures that food processing quality meets standards, while using preventive maintenance functions to ensure continuous operation of equipment.

4. Energy and Environmental Protection Industry

In scenarios such as energy production and environmental monitoring, key parameters of boiler temperature and exhaust gas treatment equipment can be controlled and monitored, and data upload and remote control can be achieved through communication interfaces to improve system operation and maintenance efficiency.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-