FOXBORO P0916JP is a series control module specifically designed for I/A Series distributed control systems. It adopts a modular structure design, has good compatibility and scalability, and can be seamlessly integrated into existing I/A control systems. This module is based on a microprocessor and combines high-precision signal acquisition and processing technology to achieve real-time monitoring and serial control of multiple industrial parameters. Through logical operations, it outputs precise control signals to drive the actions of the executing mechanism, thereby maintaining the stability and safety of the production process.

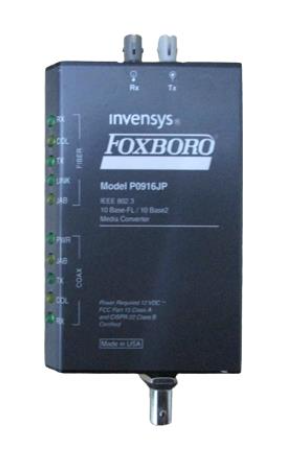

FOXBORO P0916JP I/A series control module

Basic overview of module

FOXBORO P0916JP is a series control module specifically designed for I/A Series distributed control systems. It adopts a modular structure design, has good compatibility and scalability, and can be seamlessly integrated into existing I/A control systems. This module is based on a microprocessor and combines high-precision signal acquisition and processing technology to achieve real-time monitoring and serial control of multiple industrial parameters. Through logical operations, it outputs precise control signals to drive the actions of the executing mechanism, thereby maintaining the stability and safety of the production process.

Compared with ordinary control modules, the core advantage of P0916JP lies in its "serial control" feature, which can achieve chain control of multiple links and devices according to preset logical order or dependency relationships. It is particularly suitable for industrial scenarios with strict process sequence requirements, effectively avoiding logical conflicts and misoperation risks under a single control mode.

Core functions and control features

1. High precision signal acquisition and conversion

The module has multiple analog and digital input interfaces, which can directly collect key parameters such as temperature, pressure, flow rate, and liquid level in industrial sites. Among them, the analog input supports 4-20mA standard current signals or 0-10V standard voltage signals, with an acquisition accuracy of ± 0.1% FS, ensuring the accuracy of signal acquisition; The digital input can receive dry contacts and NPN/PNP level signals, which are used to monitor the operating status of the equipment (such as "run/stop", "fault/normal", etc.). The collected signals are processed by the signal conditioning circuit and A/D conversion module inside the module, and converted into digital signals recognizable by the microprocessor, providing reliable data support for subsequent control operations.

2. Flexible series control logic

As a core function, P0916JP supports multiple series control modes, which can be customized according to production process requirements:

-Sequential control mode: Control multiple devices to start or stop in sequence according to a preset time or condition sequence. For example, in the chemical reaction process, the feed pump is controlled to start first, and the stirring equipment is started after a preset time delay to ensure that the feeding is completed before stirring and avoid material accumulation.

-Dependency control mode: Using the state of a device or parameter as a prerequisite for controlling another device. For example, the feed pump can only be started when the liquid level sensor detects that the tank level has reached the preset lower limit value; When the liquid level reaches the upper limit, the feed pump will automatically stop, achieving a series chain control of "liquid level feed".

-Fault chain protection: When the module detects a fault signal in a certain link (such as equipment overload or parameter exceeding), it immediately triggers the series protection logic, controls the relevant equipment to stop urgently or switch to a safe state, and prevents the fault from spreading. For example, when the temperature sensor detects that the temperature of the reactor exceeds the safe threshold, the module can quickly cut off the power supply of the heating equipment, start the cooling system, and issue a fault alarm signal.

3. Reliable output control and driving

The module is equipped with multiple analog and digital output interfaces, which can output corresponding control signals based on the results of control logic operations. The analog output supports 4-20mA current signals or 0-10V voltage signals, which are used to control the opening or speed of actuators such as regulating valves and frequency converters; Digital output can provide relay contacts or transistor outputs for directly controlling the start and stop of equipment. The output signal has overcurrent and overvoltage protection functions, which can effectively avoid damage to the module caused by external load abnormalities and improve the reliability of control.

4. Communication and data interaction capabilities

The P0916JP module supports dedicated communication protocols for I/A Series systems and can achieve real-time data exchange with controllers, operation stations, and other modules through the system bus. The module can upload the collected on-site parameters to the controller and operation station, facilitating real-time monitoring of production status by operators; At the same time, it can receive control instructions from the operation station or controller, adjust control logic or parameter settings. In addition, the module has the function of uploading fault diagnosis data. When it or the monitored equipment malfunctions, it can immediately upload the fault code and related information to the system, providing a basis for troubleshooting.

5. Dual control of local and remote

The module supports two modes: local manual control and remote automatic control. In local mode, operators can directly set parameters, start/stop control outputs through buttons or dip switches on the module, which is suitable for equipment debugging or emergency operation scenarios; In remote mode, the module runs completely according to the instructions issued by the controller or operation station, achieving automated control of the production process. The two modes can be flexibly switched through a toggle switch and have a mode status indication function, making it easy for operators to identify the current control mode.

Key technical parameters

Power parameters

Rated working voltage

24V DC(±10%)

Rated working current

≤500mA

power protection

Overcurrent, Overvoltage, and Reverse Connection Protection

power consumption

≤12W

input parameters

Analog input

8 channels, 4-20mA DC/0-10V DC, accuracy ± 0.1% FS

Digital input

16 channels, dry contact/PNP/PNN (optional), response time ≤ 1ms

input impedance

Analog input ≥ 10M Ω, digital input ≤ 1k Ω

output parameters

Analog output

4-channel, 4-20mA DC/0-10V DC, load capacity ≤ 500 Ω

digital output

8 channels, relay output (AC250V/5A, DC30V/10A) or transistor output

output accuracy

Analog output ± 0.2% FS, digital output response time ≤ 1ms

environmental parameters

Operating Temperature

-20℃~60℃

relative humidity

5%~95% (no condensation)

Communication parameters

communication protocol

I/A Series dedicated bus protocol

Communication speed

1Mbps~10Mbps (adaptive)

physical parameters

Overall dimensions

160mm x 80mm x 120mm (length x width x height), standard DIN rail installation

Typical application scenarios

Based on its powerful series control capability and high reliability, the FOXBORO P0916JP module has been widely used in multiple industrial fields, with typical scenarios including:

1. Petrochemical industry - reactor process control

In chemical reaction production, there is a strict series relationship between the temperature, pressure, feed rate, stirring speed and other parameters of the reaction kettle. The P0916JP module can collect real-time temperature and pressure signals of the reaction kettle. When the temperature reaches the preset value, it automatically controls the feed pump to feed according to the set flow rate; After the feeding is completed, start the mixing equipment in series and adjust the mixing speed in real time according to the pressure changes; After the reaction is complete, control the relevant equipment in the order of "stop stirring → close feed → open discharge" to ensure the orderly progress of the reaction process and avoid safety accidents caused by parameter disorder.

2. Power industry - boiler feedwater control system

In the thermal power boiler system, feedwater control directly affects the safety and efficiency of the boiler. P0916JP module can control equipment such as feed water pump, regulating valve and liquid level sensor in series: when the liquid level of boiler drum is lower than the lower limit value, the module first controls the start of feed water pump, regulates the opening of regulating valve after delay, and dynamically adjusts the feed water flow according to the change of liquid level; When the liquid level reaches the upper limit, first turn off the regulating valve, then stop the feedwater pump, and at the same time, link it with the boiler pressure signal to ensure the stability of the feedwater process and avoid boiler failure caused by high or low liquid level.

3. Metallurgical industry - temperature control of steelmaking furnaces

In steelmaking production, the heating, insulation, and cooling processes of the steelmaking furnace require strict series control. The P0916JP module can collect temperature signals inside the steelmaking furnace, combined with parameters such as oxygen flow rate and fuel supply, and control related equipment in the order of "preheating → heating → insulation → cooling": start the fan in the preheating stage, increase the fuel and oxygen supply in the heating stage, maintain stable output in the insulation stage, gradually reduce the fuel supply and start the cooling system in the cooling stage, and ensure smooth connection between each stage through serial logic to improve the quality of molten steel.

4. Water treatment industry - sewage treatment process control

In the sewage treatment system, equipment such as grilles, sedimentation tanks, aeration tanks, and sedimentation tanks need to be operated in series according to the process. The P0916JP module can control the grid to start for solid-liquid separation based on the sewage flow signal. After the sewage enters the sedimentation tank, the mixing equipment is started. After a delay, the sewage is sent to the aeration tank and the aeration fan is controlled to start; When the dissolved oxygen in the aeration tank reaches the preset value, the series control sedimentation tank sludge discharge equipment is activated to achieve automatic series control of various stages of sewage treatment and improve treatment efficiency.

Key points for installation and maintenance

1. Installation specifications

-Installation environment: It should be installed in a dust-free, non corrosive gas, well ventilated control cabinet, avoiding direct sunlight and severe vibration. The ambient temperature and humidity should meet the module parameter requirements.

-Wiring requirements: Strictly follow the module wiring diagram for wiring, distinguish between analog and digital input and output interfaces, and avoid module damage caused by wiring errors; Power lines and signal lines should be laid separately to reduce electromagnetic interference; The wiring terminals need to be tightened to prevent poor contact.

-Grounding treatment: The module casing must be reliably grounded with a grounding resistance of ≤ 4 Ω to ensure electromagnetic compatibility and personal safety.

2. Daily maintenance

-Regular inspection: Check the status of module indicator lights (power light, running light, fault light) every week to ensure that the indicator lights display normally; Check the wiring terminals for looseness every month and clean the dust on the surface of the module and inside the control cabinet.

-Parameter calibration: Calibrate the analog input and output accuracy of the module every six months, using a standard signal source and multimeter for testing. If the deviation exceeds the allowable range, it needs to be adjusted through software or local buttons.

-Fault handling: When a module malfunctions, the fault code can be viewed through the operation station and the cause can be investigated based on the fault code. Common faults include power supply faults (check power supply voltage and wiring), communication faults (check bus connection and protocol configuration), and input-output faults (check external sensors and actuators). After troubleshooting, the module needs to be restarted to restore normal operation.

3. Precautions

During the operation of the module, it is prohibited to plug and unplug the wiring terminals with power on; When modifying or maintaining parameters, it is necessary to first switch the module to "local" mode to avoid interference from remote control commands; When replacing a module, it is necessary to ensure that the model and firmware version of the new module are consistent with the original module to avoid compatibility issues.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-