The FOXBORO P0916JQ PLC module is an important component of the FOXBORO I/A Series (Intelligent Automation Series) control system, mainly responsible for core tasks such as digital or analog signal acquisition, data processing, logic control, and instruction execution. This module adopts a modular design, which is not only easy to install and maintain, but also can be flexibly combined with other I/O modules, processor modules, etc. according to actual control needs to build an automation control system that is suitable for different industrial scenarios. Its design strictly follows industrial standards and can operate stably in complex temperature, humidity, and electromagnetic interference environments, providing strong guarantees for the continuity and safety of industrial production.

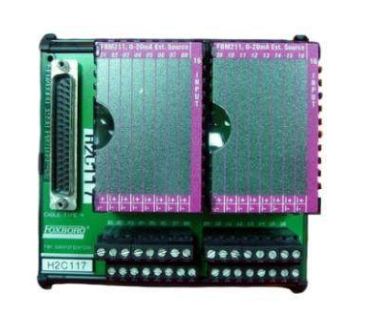

FOXBORO P0916JQ PLC module

Module Core Overview

The FOXBORO P0916JQ PLC module is an important component of the FOXBORO I/A Series (Intelligent Automation Series) control system, mainly responsible for core tasks such as digital or analog signal acquisition, data processing, logic control, and instruction execution. This module adopts a modular design, which is not only easy to install and maintain, but also can be flexibly combined with other I/O modules, processor modules, etc. according to actual control needs to build an automation control system that is suitable for different industrial scenarios. Its design strictly follows industrial standards and can operate stably in complex temperature, humidity, and electromagnetic interference environments, providing strong guarantees for the continuity and safety of industrial production.

Key technical parameters

Technical parameters are the core indicators for measuring module performance, and the parameter configuration of FOXBORO P0916JQ fully meets the actual needs of industrial control, as follows:

1. Basic parameters

-Module type: Digital input/output (I/O) module (specific types can be subdivided according to actual models, some versions are dedicated functional modules)

-Applicable system: FOXBORO I/A Series DCS/PLC control system

-Power requirements: The typical operating voltage is 24V DC (direct current), with an allowable voltage fluctuation range of ± 10% and a power consumption of ≤ 5W (no-load state)

-Working environment: Temperature range 0 ℃ -60 ℃, relative humidity 10% -90% (no condensation), altitude ≤ 2000m

-Installation method: Standard DIN rail installation, compatible with I/A Series cabinet layout

2. Signal processing parameters

-Input channel: 16 digital inputs (default NPN type, supports PNP switching)

-Output channel: 8-channel digital output (relay output, contact capacity 2A/250V AC, 2A/30V DC)

-Response time: Input response ≤ 1ms, output delay ≤ 5ms

-Signal isolation: Optical isolation is used between channels, with an isolation voltage of ≥ 2500V AC (1 minute), effectively resisting electromagnetic interference

-Diagnostic function: Supports channel level fault diagnosis, including short circuit, overcurrent, disconnection and other fault alarms, and provides real-time feedback through LED indicator lights

3. Communication and compatibility parameters

-Communication interface: Communicate with the processor module through the system backplane bus, with a bus speed of ≥ 1Mbps

-Compatible modules: can seamlessly integrate with FOXBORO P0917X, P0926W and other series processor modules, as well as P0914Y, P0915Z and other I/O modules

-Programming support: Supports FOXBORO Control Builder programming software, compatible with programming methods such as ladder diagram (LD), functional block diagram (FBD), structured text (ST), etc

Core functions and advantages

The FOXBORO P0916JQ module fully integrates the practicality and reliability requirements of industrial control in its design, and has the following core functions and advantages:

1. Efficient signal processing capability

The module adopts high-performance microprocessors, which can quickly collect input signals and execute control logic. The input response time can reach as short as 0.5ms, ensuring rapid response to real-time changes in the industrial field. At the same time, the output channel adopts a stable relay contact design, supports frequent on-off operations, and has a service life of over 1 million times, meeting the high-frequency control requirements of continuous production.

2. Comprehensive fault diagnosis and protection

The module is equipped with a comprehensive fault diagnosis mechanism, which can monitor the working status of each channel in real time. When there are situations such as input disconnection, output short circuit, overcurrent, or power abnormality, not only will the local alarm be triggered through the LED indicator lights on the module surface (such as fault lights and running lights), but the fault information will also be uploaded to the system controller for operators to quickly locate the problem. In addition, the module has overvoltage protection and surge suppression functions, which can effectively resist the impact of power grid fluctuations on the module and extend the service life of the equipment.

3. Flexible modularity and compatibility

Following the modular design specifications of FOXBORO I/A Series, the P0916JQ module can be flexibly added or removed according to the size of the control system, and supports hot swapping operations (some versions), which means that module replacement can be completed without shutting down the system, greatly reducing maintenance costs and production interruption risks. At the same time, it is compatible with multiple programming methods and system configuration software, making it easy for engineers to develop and debug programs according to project requirements.

4. Industrial grade reliability design

The module casing is made of high-strength metal material, which has good dustproof and moisture-proof performance; The internal circuit adopts anti-interference design and has passed EMC (electromagnetic compatibility) certification, which can work stably in strong electromagnetic environments in industrial sites, avoiding control errors caused by interference. In addition, its wide temperature working range design enables it to adapt to the environmental requirements of different regions and working conditions, whether it is a high-temperature metallurgical workshop or a humid chemical plant area, it can operate reliably.

Typical application scenarios

With stable performance and flexible adaptability, the FOXBORO P0916JQ PLC module is widely used in multiple industrial fields, with typical scenarios including:

1. Petrochemical industry

In the production processes of petroleum refining and chemical synthesis, modules are used to collect operational status signals (such as start stop status and fault signals) of pumps, valves, heat exchangers, and other equipment, and output control instructions to achieve interlocking control, emergency shutdown, and other functions of the equipment, ensuring the safety and stability of the production process.

2. Power industry

In power plant systems such as thermal power and hydropower, modules can be used to monitor parameters such as temperature, pressure, and current of generator sets, transformers, and transmission and distribution equipment, while controlling the operation of cooling and lubrication systems to ensure continuous and reliable power production.

3. Metallurgical industry

In the process of steel and non-ferrous metal smelting, modules are used to collect operational data of equipment such as blast furnaces and converters, control the start stop and adjustment of batching systems and conveying systems, achieve automated control of the smelting process, and improve production efficiency and product quality.

4. Manufacturing industry

In production lines such as automobile manufacturing and mechanical processing, modules are used to achieve sequential control and process linkage of equipment, collect signals such as material position and equipment status on the production line, and ensure efficient operation and precise control of the production line.

Precautions for use

To ensure the stable operation and service life of the FOXBORO P0916JQ PLC module, the following precautions should be taken during installation, use, and maintenance:

1. Installation specifications: Before installation, it is necessary to check whether the appearance of the module is intact and whether the wiring terminals are loose; During installation, it is necessary to strictly follow the DIN rail installation requirements to ensure that the module is in close contact with the rail and avoid poor contact caused by vibration. At least 5cm of heat dissipation space should be reserved between modules to prevent performance degradation in high-temperature environments.

2. Wiring requirements: Before wiring, it is necessary to confirm that the power supply voltage is consistent with the rated voltage of the module to avoid overvoltage damage to the module; The input/output signal lines should be wired separately from the power lines to reduce electromagnetic interference; When wiring, it is necessary to firmly connect to avoid signal loss or equipment misoperation caused by poor contact.

3. Debugging and maintenance: Before the first use, it is necessary to configure the module parameters and download the program through programming software to ensure normal communication with the system controller; During daily maintenance, it is necessary to regularly check the status of the LED indicator lights of the module, promptly detect faults and handle them; Regularly clean the dust on the surface of the module, maintain smooth heat dissipation, and avoid short circuit faults caused by dust accumulation.

4. Environmental control: Avoid installing modules in damp, dusty, corrosive gas or strong electromagnetic interference environments. If the on-site environment is harsh, protective cabinets should be equipped or corresponding protective measures should be taken (such as moisture-proof, dust-proof, shielding).

5. Spare parts and replacement: When replacing modules, choose products of the same model and specifications. Before replacement, disconnect the module power supply to avoid short circuits caused by live operation; After replacement, it is necessary to reconfigure and debug the parameters to ensure compatibility with the system.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-