FOXBORO PBCO-D8-009 is a high-performance digital output module developed by Foxboro for industrial automation control, belonging to the core I/O module family of Foxboro I/A Series distributed control system (DCS). This module serves as a key interface between the control system and the on-site execution mechanism, capable of reliably converting digital control instructions issued by the upper PLC and DCS systems into switch signals that can drive external execution components, achieving precise start stop control and status switching of equipment such as valves, relays, contactors, indicator lights, etc. It adopts industrial grade reinforced design, with excellent anti-interference ability and stable operating performance. Combined with modular architecture and standardized installation methods, it simplifies system integration and operation and maintenance processes, and is widely suitable for automation control scenarios in various harsh industrial environments such as petrochemicals, power, water treatment, and manufacturing.

FOXBORO PBCO-D8-009 Digital Output Module

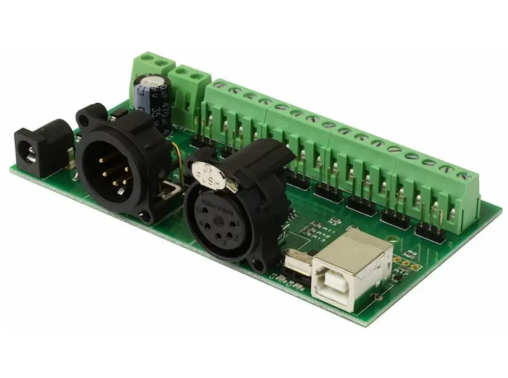

Product Overview

FOXBORO PBCO-D8-009 is a high-performance digital output module developed by Foxboro for industrial automation control, belonging to the core I/O module family of Foxboro I/A Series distributed control system (DCS). This module serves as a key interface between the control system and the on-site execution mechanism, capable of reliably converting digital control instructions issued by the upper PLC and DCS systems into switch signals that can drive external execution components, achieving precise start stop control and status switching of equipment such as valves, relays, contactors, indicator lights, etc. It adopts industrial grade reinforced design, with excellent anti-interference ability and stable operating performance. Combined with modular architecture and standardized installation methods, it simplifies system integration and operation and maintenance processes, and is widely suitable for automation control scenarios in various harsh industrial environments such as petrochemicals, power, water treatment, and manufacturing.

Detailed explanation of core functions

2.1 Multi channel digital output driver

The module integrates 8 independent digital output channels, supporting the simultaneous driving of multiple external actuators. Each channel has an independent driving circuit and protection mechanism, and can be flexibly configured as normally open or normally closed output mode according to on-site requirements. The output signal can be directly adapted to commonly used DC 24V or AC 220V actuators in industry, without the need for additional power amplification modules. It can efficiently control devices such as solenoid valves, small motors, alarm indicators, etc., greatly improving the integration and convenience of system control.

2.2 High precision output control and state feedback

The module has the ability to quickly output and respond, with an output signal switching response time of ≤ 5ms. It can accurately capture the control instructions of the upper system, ensuring the timeliness and synchronization of the actuator actions. At the same time, the module is equipped with a channel status monitoring circuit, which can collect the actual working status (on/off) of each output channel in real time, and feedback the status information to the upper control system, forming a control loop, making it convenient for operation and maintenance personnel to grasp the operating status of the actuator in real time, detect and handle output faults in a timely manner.

2.3 Flexible fault alarm and interlocking control

Support user-defined fault alarm logic, which can set alarm thresholds and trigger conditions for abnormal working conditions such as output channel overload, short circuit, and disconnection. When a channel fault is detected, the module can immediately output an alarm signal and automatically cut off the output of the faulty channel to prevent the fault from expanding and affecting the normal operation of other channels; In addition, the module can be interlocked with other modules within the system (such as input modules) to quickly trigger preset emergency control actions (such as emergency shutdown and valve cut-off) when receiving a bottom position abnormal signal, ensuring the safety of the production process.

2.4 Standardized communication and remote operation and maintenance

The module is equipped with dual serial communication interfaces of RS232 and RS485, and natively supports Modbus industrial communication protocol. It can seamlessly integrate into various industrial communication networks and achieve efficient data exchange with the upper control system and human-machine interface (HMI). Through the communication interface, users can remotely issue control commands, configure module operating parameters (such as output mode, alarm threshold), and remotely read module output status, fault records, and other information, achieving remote monitoring and operation management of the module, greatly reducing on-site operation and maintenance workload.

2.5 Multiple security protection mechanisms

The module is equipped with multiple safety protection circuits such as overload protection, short circuit protection, overvoltage protection, and power reverse protection, which comprehensively ensure the safe operation of the module itself and external actuators. Among them, the overload and short circuit protection function can quickly cut off the channel circuit when the output current exceeds the rated range or a short circuit occurs, avoiding damage to internal components and external execution components of the module; The overvoltage protection function can effectively resist the impact caused by voltage fluctuations in the power grid; Reverse power protection can prevent module burnout caused by wiring errors, further improving the reliability of system operation.

Detailed technical parameters

output parameters

Output type: dry contact/wet contact (configurable); Number of channels: 8 independent output channels; Output voltage range: DC 12-24V or AC 110-220V; Maximum output current per channel: 2A (resistive load); Output response time: ≤ 5ms; output mode: normally open/normally closed (software configurable)

communication parameters

Communication interface: RS232, RS485; Supported protocols: Modbus RTU/TCP; Communication speed: 9600-115200bps (adjustable); Data bits/check bits: 8N1, 8E1, 8O1 (configurable); Communication distance: RS485 interface with a maximum communication distance of 1200m

Working environment parameters

Working temperature range: -10 ℃ to+60 ℃; Storage temperature range: -40 ℃ to+85 ℃; Relative humidity: 5%~95% (no condensation); Protection level: IP20 (module body); Anti electromagnetic interference capability: compliant with IEC 61000-4-2/3/4/5 series standards; Vibration level: in accordance with IEC 60068-2-6 standard

Power parameters

Power supply voltage: DC 24V (± 10%); Power consumption: Static power consumption ≤ 3W, full load power consumption ≤ 15W; Power supply mode: external DC power supply, supporting redundant power supply access

mechanical parameters

Dimensions (length x width x height): 140mm x 100mm x 35mm; Weight: approximately 250g; Installation method: DIN rail installation (compatible with standard 35mm rail); Shell material: flame retardant ABS engineering plastic; Wiring method: plug-in terminal (screw fastening)

protection parameters

Protection types: overload protection, short circuit protection, overvoltage protection, power reverse connection protection; Overload protection threshold: 2.5A per channel (automatic cut-off); Short circuit protection response time: ≤ 10 μ s

Core product features

4.1 High reliability industrial grade design

The module adopts full industrial grade component selection and undergoes strict high and low temperature cycle testing, vibration testing, electromagnetic compatibility testing, and aging testing. It can operate stably in industrial sites with a wide temperature range of -10 ℃ to+60 ℃, high dust, and strong electromagnetic interference. The flame-retardant ABS shell has good impact resistance and corrosion resistance, effectively protecting the internal circuit from on-site environmental damage and ensuring the reliability of the module's long-term continuous operation.

4.2 Modular architecture, easy installation, operation and maintenance

Adopting standardized modular design and DIN rail installation method, it does not require complex mechanical processing and can be directly embedded into the rails inside standard industrial control cabinets. The installation process is simple and efficient; The module adopts plug-in terminal blocks, which are convenient for on-site wiring, line maintenance, and module replacement; At the same time, the module is equipped with a comprehensive status indicator function, which can intuitively judge the power status, communication status, and output status of each channel through the top LED indicator light, helping operation and maintenance personnel quickly locate the fault point.

4.3 Independent protection for all channels, safe and reliable operation

Each output channel is equipped with independent overload and short-circuit protection circuits. When a channel fails, only the output of that channel is cut off, without affecting the normal operation of other channels, greatly improving the stability and safety of system operation. At the same time, the module as a whole has multiple protections such as overvoltage and power reverse connection, effectively resisting various electrical fault risks and reducing the probability of equipment damage.

4.4 Flexible configuration, adaptable to diverse needs

Support remote configuration of output channel working modes (normally open/normally closed), alarm thresholds, and other parameters through the upper system or dedicated configuration software. It can adapt to different types of external actuators and control scenarios without the need to replace hardware, greatly improving the universality and flexibility of the module. In addition, the module supports redundant power supply access, which can further enhance the reliability of system power supply and is suitable for critical control scenarios that require high power supply stability.

4.5 Precise control and status feedback, closed-loop management is more efficient

The module has fast output response speed and accurate status monitoring capability, which can provide real-time feedback on the actual operating status of each channel, forming a control loop of "instruction issuance execution status feedback". This closed-loop management mode not only ensures the effective execution of control instructions, but also facilitates operation and maintenance personnel to grasp the real-time operation status of on-site equipment, predict potential faults in advance, and improve system operation and maintenance efficiency.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-