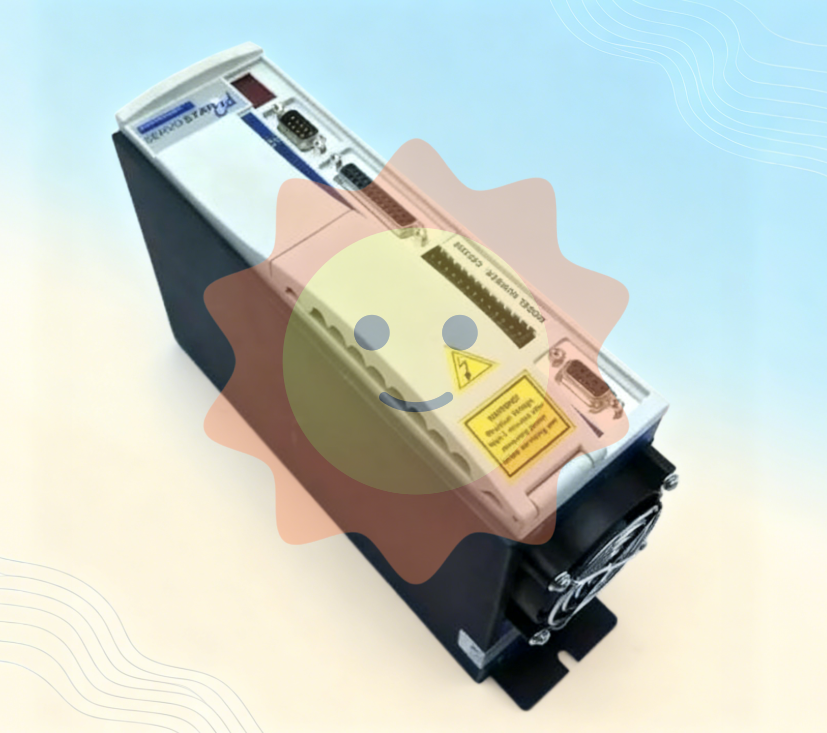

Kollmorgen NEAT 310M - Programmable Motion Controller

The Kollmorgen NEAT 310M is a robust and versatile automation solution engineered to meet the rigorous demands of the power industry, petrochemical sectors, and general automation environments. Built with precision and durability in mind, the NEAT 310M stands out for its exceptional input/output capacity, high-performance metrics, and long-lasting reliability, making it a cornerstone in advanced industrial automation systems. At the heart of the Kollmorgen NEAT 310M is its powerful I/O architecture that supports high-density signal processing, allowing seamless integration with complex control systems. The unit offers a balanced combination of analog and digital inputs and outputs, ensuring accurate real-time data acquisition and control. Its input voltage tolerance and output current capabilities are optimized for heavy-duty industrial applications, providing stable and precise control over machinery and process parameters. The NEAT 310M operates efficiently under harsh environmental conditions, showcasing superior resistance to electrical noise, temperature extremes, and mechanical vibrations, which are common challenges in power plants and petrochemical facilities. Performance-wise, the NEAT 310M excels with fast response times and high data throughput, critical for applications requiring rapid feedback loops and stringent safety compliance.

Its architecture supports advanced diagnostic and monitoring functions, giving operators detailed insight into system health and operational status. This feature enhances predictive maintenance strategies and reduces downtime, a vital advantage in industries where continuous operation is paramount. In real-world scenarios, the application of the NEAT 310M in the power industry includes turbine control systems, transformer management, and substation automation, where precise and reliable control signals are essential. In petrochemical plants, the NEAT 310M contributes to process automation, including flow control, pressure monitoring, and safety interlocks, ensuring both efficiency and compliance with stringent safety standards. General automation industries benefit from the NEAT 310M’s adaptability in manufacturing lines, robotics integration, and material handling systems where high-speed, accurate control is necessary for productivity and quality assurance.

When compared to other Kollmorgen automation products, such as the Kollmorgen DIGIFAS 7200, which specializes in advanced drive management, or the Kollmorgen AKM43L-ACD2CA00 servo motor known for its high torque density, the NEAT 310M offers a unique advantage in its I/O versatility and ruggedness. Unlike the Kollmorgen PS244/E power supply designed for stable energy delivery or the Kollmorgen AKD-P00607-NBCC-I000 servo drive known for precision motor control, the NEAT 310M functions as a critical interface module, bridging control logic and physical devices with high reliability. Alongside the Kollmorgen NEAT 310M, complementary models such as the Kollmorgen MT1504A1-E-2C3 provide specialized motor control capabilities, while the Kollmorgen PJT55 excels in industrial sensing solutions. The Kollmorgen 67WKS-M240/3-PB offers another layer of power conversion robustness, and the Kollmorgen M.1301.4013 controller enhances programmable logic control applications. For applications requiring compact servo solutions, the Kollmorgen AKM42E-ANCNR-00 and AKM11B-ANCNR-00 motors are excellent choices. Additionally, the Kollmorgen CE03560 encoder series ensures precise position feedback, critical for closed-loop control systems integrated with the NEAT 310M.

The Kollmorgen TB03500 terminal blocks facilitate seamless wiring, and the Kollmorgen MH-225-G-61 sensor modules complement the NEAT 310M by providing environmental data inputs for enhanced automation accuracy. The Kollmorgen NEAT 310M is designed with scalability in mind, allowing users to expand control system capabilities without sacrificing performance. Its compatibility with a broad range of Kollmorgen products ensures a cohesive automation ecosystem tailored to specific industry needs. Whether used in the demanding conditions of a petrochemical refinery or the precise environment of a power generation plant, the NEAT 310M consistently delivers reliability and precision. For organizations seeking dependable and high-performing automation components, the Kollmorgen NEAT 310M represents a strategic investment. Its integration within Kollmorgen’s extensive product portfolio, including models like the AKM31H-ANC2EG00 and M.1302.6401 controllers, empowers engineers to build sophisticated, efficient, and resilient automation systems. This makes the NEAT 310M a vital asset in the evolving landscape of industrial automation.

In summary, the Kollmorgen NEAT 310M offers unmatched input/output capacity, durability, and performance tailored specifically for the power industry, petrochemical, and general automation sectors. Combined with the complementary Kollmorgen automation products such as the DIGIFAS 7200, MT1504A1-E-2C3, PJT55, and AKM43L-ACD2CA00, it provides a comprehensive solution that enhances operational efficiency, safety, and system longevity. Choosing the NEAT 310M means embracing a future of reliable, high-precision automation designed to meet the toughest industrial challenges.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-