ABB SC540 3BSE006096R1 is a high-performance submodule carrier for the industrial automation field, belonging to the core hardware component of ABB PLC control system. It mainly undertakes the key functions of submodule integration installation, signal conversion, and system interconnection. Its model code follows the ABB Industrial Control Product Specification, with "SC540" as the base model, specifying its product category as a submodule carrier; 3BSE006096R1 "is the standard spare part code, where" 3BSE "represents the PLC and control product series, and" R1 "indicates the hardware benchmark version.

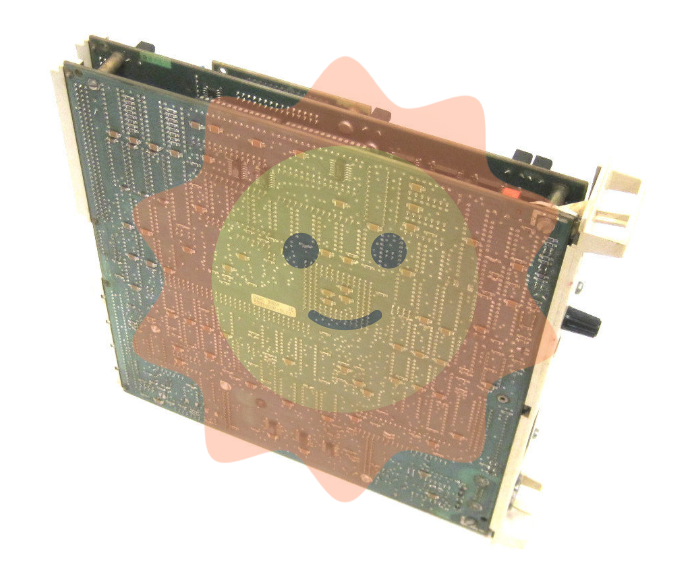

ABB SC540 3BSE006096R1 Submodule Carrier

Product Overview

ABB SC540 3BSE006096R1 is a high-performance submodule carrier for the industrial automation field, belonging to the core hardware component of ABB PLC control system. It mainly undertakes the key functions of submodule integration installation, signal conversion, and system interconnection. Its model code follows the ABB Industrial Control Product Specification, with "SC540" as the base model, specifying its product category as a submodule carrier; 3BSE006096R1 "is the standard spare part code, where" 3BSE "represents the PLC and control product series, and" R1 "indicates the hardware benchmark version.

This carrier adopts a standardized modular design and is compatible with various types of sub modules such as digital input/output (DI/DO) and analog input/output (AI/AO). Through an internal bus, high-speed data exchange between the sub modules and the PLC main controller is achieved. It is the core hub for building flexible and scalable industrial control systems and widely applicable to complex automation scenarios such as metallurgy, power, and manufacturing.

Specification parameters

Electrical characteristics

Working voltage: DC 24V (allowable fluctuation range ± 10%); Bus communication voltage: 5V DC; Module power supply current: maximum 1.5A

Interface configuration

Submodule slots: Supports 4-8 standard I/O submodule slots; Communication interface: Integrated PLC system internal bus interface; Signal terminal: adopts spring type wiring terminal, suitable for 1.5-2.5mm ² copper core cable

Performance parameters

Signal transmission rate: up to 100Mbps; Response time: ≤ 1ms (submodule signal to bus); Support submodule types: DI/DO, AI/AO, relay output, dedicated functional modules, etc

Environment and Structure

Working temperature: 0 ℃~+60 ℃; Storage temperature: -20 ℃~+85 ℃; Protection level: IP20 (suitable for installation inside control cabinets); Installation method: 35mm DIN rail installation or panel installation

Performance characteristics

High compatibility modular design: adopting standardized slot interfaces, it can flexibly carry ABB's full range of I/O submodules and dedicated functional modules, and can achieve functional expansion and reconstruction of the control system without changing the carrier hardware, adapting to diverse requirements from simple equipment control to complex process automation.

High speed signal transmission capability: Equipped with an optimized bus communication circuit, the signal transmission rate can reach 100Mbps, and the response time is controlled within 1ms. It can transmit real-time on-site data collected by submodules and execution instructions issued by the controller, ensuring the real-time and accuracy of industrial control.

Reliable electrical protection performance: The hardware level integrates overvoltage and overcurrent protection circuits, and the submodule interface has photoelectric isolation function (isolation voltage ≥ 2500V AC), which can effectively resist electromagnetic interference and voltage fluctuations in industrial sites, reduce signal transmission errors and equipment damage risks.

Convenient operation and maintenance adaptability: equipped with module status indicator lights (power, communication, fault indicator lights), which can intuitively feedback the operating status; Support hot swappable function (for some sub module types), which allows for the replacement of sub modules without shutting down the entire system during operation and maintenance, reducing downtime for maintenance.

Working principle

The ABB SC540 submodule carrier is based on the core working mechanism of "interface adaptation signal transfer bus communication", and the specific process is as follows:

Sub module interface adaptation: External I/O sub modules are mechanically connected to the carrier through standardized slots and achieve electrical docking. The carrier provides stable DC 24V working power supply for the sub modules, and at the same time, receives analog/digital signals collected by the sub modules through dedicated pins, or sends controller output instructions to the sub modules.

Signal processing and transfer: The internal signal processing circuit of the carrier filters, isolates, and level converts the received field signals, optimizes the analog signals into digital signals suitable for bus transmission, or converts controller instructions into identifiable driving signals for submodules, ensuring the stability and accuracy of signal transmission.

Bus communication interaction: Establish a connection with the PLC main controller through an internal high-speed bus interface, upload real-time field data of submodules to the controller according to the system communication protocol, and receive control instructions issued by the controller and allocate them to corresponding submodules, achieving a closed-loop process of "field perception control decision execution response".

Status monitoring and protection: Real time monitoring of submodule power supply voltage, communication link status, and its own operating temperature. When abnormalities such as overvoltage, overcurrent, and communication interruption are detected, the fault indicator light alarm is immediately triggered, and fault information is uploaded to the controller through the bus. At the same time, the power supply of the faulty submodule is cut off to avoid fault propagation.

Precautions

Selection and compatibility matching: It is necessary to select the appropriate submodule type according to the control system requirements, ensuring that the submodule pin definitions are compatible with the carrier slots; Simultaneously confirm the bus protocol matching between the carrier and the PLC main controller (such as ABB AC800M series controller) to avoid communication compatibility issues.

Installation and wiring specifications: It should be installed in a closed PLC control cabinet, away from strong interference sources such as high-power motors and high-frequency equipment. The cooling and ventilation space of the control cabinet should not be less than 500mm to ensure heat dissipation; Strong and weak electrical lines need to be wired separately, and communication cables use shielded twisted pair cables. The shielding layer is grounded at one end (grounding resistance ≤ 4 Ω) to reduce the impact of electromagnetic interference.

Debugging and commissioning process: Before commissioning, it is necessary to check whether the submodule installation is firm and whether the terminal wiring is correct; Perform bus address configuration and communication testing on the carrier through PLC programming software to verify that the submodule signal acquisition and instruction execution functions are normal; After debugging, lock the module parameters to prevent configuration loss caused by misoperation.

Maintenance and troubleshooting: Regularly (quarterly) check the status of the carrier indicator lights, the cleanliness of the slot contact points, and the tightness of the wiring; If there is a communication interruption fault, it is necessary to check the bus cable connection, address configuration, and controller communication port status; If the submodule does not respond, you can try unplugging the module or replacing the spare module. For troubleshooting, please contact an authorized ABB service provider and do not disassemble the carrier hardware on your own.

Application scenarios

Manufacturing production line control: As an integrated carrier of I/O modules in automotive parts, electronic components and other production lines, it connects sensors (such as photoelectric sensors, proximity switches) and actuators (such as solenoid valves, servo motors) to achieve precise control of material detection, equipment start stop and other functions during the production process, adapting to the rapid reconstruction needs of flexible production lines.

Metallurgical industry process monitoring: a PLC control system used for steel and non-ferrous metal smelting, equipped with analog input sub modules such as temperature and pressure, and digital output sub modules for valve control. It collects real-time parameters such as smelting furnace temperature and pipeline pressure, and controls the execution mechanism to ensure the stability and product quality of the smelting process.

Auxiliary control of power system: In the auxiliary control system of substations and power plants, current/voltage measurement submodules and relay output submodules are integrated to achieve remote monitoring and control of cooling systems, ventilation equipment, and isolation switches, and to improve the reliability of power supply in conjunction with the main protection system.

Water treatment automation system: Suitable for urban sewage treatment and industrial wastewater treatment scenarios, it is equipped with liquid level detection submodule, flow meter quantum module, and pump valve control submodule to achieve automatic operations such as sedimentation tank liquid level monitoring, filtration equipment start stop, and chemical dosage adjustment, reducing manual operation and maintenance costs.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-