YASKAWA SGDS-08A01A is a high-performance servo motor launched by Yaskawa (YASKAWA) brand. Its core positioning is high-precision power drive and positioning control for industrial automation systems, with strong power output, excellent low-speed operation stability, and precise position/speed control capabilities. It can achieve seamless integration with Yaskawa SGDS series servo drives and accurately complete industrial operation tasks with high dynamic response and high-precision positioning. This servo motor adopts a high rigidity mechanical structure design and is equipped with a high-precision absolute value encoder. It has excellent resistance to load disturbances and environmental adaptability, and is the core power execution component for improving the motion accuracy, response speed, and operational stability of precision machining, industrial robots, and other automation equipment. At present, there is sufficient stock supply of this model of servo motor, which can meet diverse needs such as building new servo systems, upgrading existing automation equipment power, and equipment maintenance.

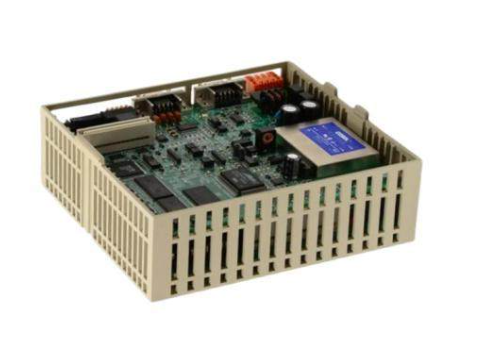

YASKAWA SGDS-08A01A High Performance Servo Motor

Product Overview

YASKAWA SGDS-08A01A is a high-performance servo motor launched by Yaskawa (YASKAWA) brand. Its core positioning is high-precision power drive and positioning control for industrial automation systems, with strong power output, excellent low-speed operation stability, and precise position/speed control capabilities. It can achieve seamless integration with Yaskawa SGDS series servo drives and accurately complete industrial operation tasks with high dynamic response and high-precision positioning. This servo motor adopts a high rigidity mechanical structure design and is equipped with a high-precision absolute value encoder. It has excellent resistance to load disturbances and environmental adaptability, and is the core power execution component for improving the motion accuracy, response speed, and operational stability of precision machining, industrial robots, and other automation equipment. At present, there is sufficient stock supply of this model of servo motor, which can meet diverse needs such as building new servo systems, upgrading existing automation equipment power, and equipment maintenance.

Core specification parameters

-Core electrical parameters: rated output power of 0.75kW, rated speed of 3000r/min, rated torque of 2.4N · m, maximum torque of 7.2N · m; Rated voltage AC 200V, rated current 4.5A; equipped with a 20 bit high-precision absolute encoder, positioning accuracy up to ± 1 arcminute, supporting real-time position feedback; Working temperature range -10 ℃~60 ℃, relative humidity ≤ 90% RH (no condensation), suitable for complex industrial workshop environment, ensuring stable operation; Insulation level F, protection level IP65, suitable for industrial scenes with high dust and slight humidity.

-Interface and adaptation features: Equipped with a standard servo motor power interface (U/V/W) for connecting to the output end of the servo drive; Equipped with an encoder signal interface, it supports high-speed position signal interaction with servo drives to achieve closed-loop position control; Adopting standard flange installation dimensions, compatible with various precision mechanical transmission structures; Compatible with Yaskawa SGDS series servo drives, while supporting collaborative control with mainstream industrial controllers (PLC, motion controllers), flexibly integrating into various precision automation system architectures.

-Drive and control performance: It has excellent dynamic response characteristics, short acceleration time (0~3000r/min acceleration time ≤ 0.2s), and can quickly respond to control instructions; Smooth low-speed operation, no crawling phenomenon, low-speed torque fluctuation ≤ ± 5%, suitable for precision feed and low-speed constant speed operation scenarios; Supports three modes: position control, speed control, and torque control, with high control accuracy, speed fluctuation rate of ≤± 0.01%, and position control repeated positioning accuracy of ≤± 0.001mm. It has good load disturbance suppression ability and can automatically compensate for speed/position deviation caused by load changes.

-Protection and structural parameters: Built in overheating protection, overcurrent protection, overload protection mechanisms, can monitor the motor operation status in real time, and timely feedback to the servo drive and cut off power when abnormalities occur, protecting the safety of the motor and related equipment; Adopting a high rigidity shaft design, it has strong impact resistance and low rotor inertia, making it easy to quickly start and stop and accurately locate; Equipped with a forced air cooling device, the heat dissipation efficiency is high, which can ensure that the motor can run continuously for a long time under rated load; Support external connection of braking resistors to achieve fast braking and energy recovery.

-Physical parameters: Weight approximately 4.8kg, flange size 100mm, motor length 210mm (including encoder); Adopting an all metal shell design, it has high mechanical strength and strong anti vibration ability (vibration level 2.5g); The installation method supports flange installation and foot installation, and is suitable for the installation needs of multiple industrial scenarios such as precision machine tools, industrial robots, and automated conveyor lines.

Core Advantage Characteristics

-High precision positioning and high-speed response: relying on a 20 bit high-precision absolute value encoder and advanced servo control algorithms, ultra high precision position positioning and real-time position feedback are achieved. Combined with fast dynamic response characteristics, high-frequency, high-precision start stop and positioning operations can be accurately completed, suitable for high-end automation scenarios such as precision machining and robot joint drive.

-Strong power and stable operation: With excellent torque output capability, the rated torque and maximum torque ratio are reasonable, making it easy to cope with complex load changes; Smooth and non crawling operation at low speeds, stable and non shaking operation at high speeds, coupled with efficient heat dissipation design, ensure long-term stable operation of the motor within the full speed range, greatly improving equipment reliability and operational stability.

-Strong environmental adaptability and high reliability: Designed with IP65 protection level, it effectively prevents dust and splashes, and is suitable for industrial workshop environments with high dust and slight humidity; F-class insulation design and high rigidity mechanical structure, with excellent anti vibration and anti impact capabilities, can operate stably in complex industrial conditions; The comprehensive built-in protection mechanism can effectively deal with abnormal working conditions such as overheating, overcurrent, and overload, greatly reducing the probability of failure.

-Convenient adaptation and maintenance: adopting standardized interfaces and installation dimensions, it can quickly connect with Yaskawa SGDS series servo drives and various precision machinery, reducing the difficulty of system integration; The encoder signal provides real-time feedback on the operating status, facilitating fault diagnosis and localization; Modular structure design, key components can be separately inspected and replaced, and with clear status identification, greatly reduces maintenance difficulty and downtime losses.

-Flexible control and wide adaptability: supports seamless switching between position, speed, and torque control modes, and can be flexibly configured according to the needs of different industrial scenarios; Compatible with the entire range of Yaskawa servo control systems and mainstream industrial controllers, it supports multiple control signal interactions and can be integrated into various automation systems such as precision machining, robotics, and automated production lines to meet personalized control needs.

Working principle

The YASKAWA SGDS-08A01A high-performance servo motor, as the core power execution component of industrial automation systems, works based on the full process servo drive logic of "electromagnetic induction drive position/speed feedback closed-loop control". Firstly, the servo motor receives three-phase AC power from the servo driver through the U/V/W power interface. The current generates a rotating magnetic field in the stator winding, and the rotor rotates with the rotating magnetic field under the action of electromagnetic attraction, outputting mechanical power to drive the load operation; At the same time, the built-in 20 bit high-precision absolute encoder of the motor collects real-time position and speed signals of the rotor, and feeds back the signals to the servo driver through the encoder interface; The servo driver compares the feedback signal with the instruction signal issued by the upper computer (PLC/motion controller), dynamically adjusts the current size and frequency output to the motor, and achieves closed-loop control of position, speed, or torque; In addition, the built-in protection circuit of the motor monitors parameters such as stator winding temperature and operating current in real time. Once abnormalities such as overheating, overcurrent, and overload are detected, the fault signal is immediately fed back to the servo driver, which quickly cuts off the power output, achieving safety protection for the motor and load equipment.

Installation and usage precautions

(1) Installation precautions

-Voltage and driver matching: Before installation, it is necessary to confirm that the output voltage and current of the servo driver are consistent with the rated parameters of the motor (AC 200V, 4.5A), to ensure accurate compatibility between the driver and motor models (priority should be given to matching Yaskawa SGDS series drivers); It is strictly prohibited to directly connect power sources that do not meet the parameters to the motor to avoid motor burnout or performance damage; When not in use for a long time, the motor should be disconnected from the driver and protected against dust and moisture.

-Installation environment requirements: The installation position of the motor should be away from strong electromagnetic interference equipment such as welding machines and high-power frequency converters to avoid electromagnetic interference affecting the transmission of encoder signals; The installation location should ensure good ventilation and maintain a distance of ≥ 50mm from other equipment to ensure smooth heat dissipation of the forced air cooling device; It is strictly prohibited to install in environments with direct sunlight, high temperature and humidity, high concentration of corrosive gases or dust, to avoid damaging the motor winding and encoder.

-Correct wiring and mechanical installation: Strictly distinguish the power interface (U/V/W) from the encoder interface according to the wiring manual, strictly prohibit misconnection or mixing, and avoid motor reversal or encoder damage; Special shielded cables should be used for power cables and encoder cables, with a distance of ≥ 300mm between them to reduce signal interference; During mechanical installation, it is necessary to ensure that the coaxiality error between the motor shaft and the load shaft is ≤ 0.02mm to avoid bearing wear or vibration caused by eccentric operation; The installation bolts should be tightened to the specified torque to prevent loosening during operation.

(2) Precautions for use and maintenance

-Parameter configuration and trial operation specifications: Before the first use, the motor parameter configuration needs to be completed through the servo drive matching software, including motor model adaptation, encoder type selection, control mode setting, position/speed parameter calibration, etc; After the parameter configuration is completed, a no-load test run is required to check whether the motor direction, speed, and vibration are normal, and then a load test run is carried out to confirm that there are no abnormalities before it can be officially put into use; Prohibit arbitrary modification of core drive parameters to avoid abnormal motor operation or decreased positioning accuracy.

-Regular maintenance: Regularly check the operating status of the motor, including shell temperature, vibration, noise level, cable connection tightness, etc; Regularly clean the motor cooling duct and fan dust to ensure smooth heat dissipation; Regularly check whether the encoder signal cable is damaged and whether the interface is loose; It is recommended to conduct a comprehensive insulation test and parameter calibration every 6 months, and check the bearing wear and add lubricating grease every 12 months.

-Fault handling specifications: When a fault occurs, it is necessary to first read the fault code through the servo drive and investigate the cause of the fault based on the motor operating status (such as checking the cooling fan and ventilation situation for overheating faults, and checking the encoder and coaxiality for positioning deviation faults); It is strictly prohibited to forcibly start the motor without troubleshooting; When replacing components such as encoders and fans, it is necessary to use Yaskawa original parts to ensure equipment compatibility and operational reliability; Complex faults require maintenance by professional technicians.

Applicable scenarios

-Precision machining scenario: suitable for precision machining equipment such as CNC lathes, machining centers, laser cutting machines, etc., responsible for spindle drive or feed axis drive, ensuring workpiece machining accuracy and surface quality through high-precision positioning and stable power output, and improving machining efficiency.

-Industrial robot drive scenario: widely used in joint drive systems of industrial robots, providing precise power output and position control for robot joints, realizing flexible motion and high-precision operation of robots, and adapting to robot automation scenarios such as welding, assembly, and grasping.

-Upgrading of existing equipment power: In response to the bottleneck of insufficient servo motor power, low positioning accuracy, and slow response speed in existing automation equipment, it can be directly replaced and upgraded with YASKAWA SGDS-08A01A servo motor to improve the power performance and control accuracy of the equipment, extend the service life of the equipment, and adapt to the development needs of modern precision industrial automation.

-High end automated production line: adapted to high-end automated production lines such as precision assembly of electronic components, semiconductor processing, and new energy battery manufacturing, responsible for the power drive of conveying mechanisms and positioning platforms, ensuring the automation level and product qualification rate of the production line through high-precision and high stability operation.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-