ABB SPAD346C is a high-precision integrated differential relay mainly used for differential protection of transformers, generators, motors, busbars and other equipment in medium and low voltage power systems. By monitoring the difference in current on both sides of the protected equipment in real time, it quickly identifies internal short circuits, inter turn short circuits and other faults, achieves millisecond level fault removal, and has complete alarm, locking and communication functions. It is the core protection device to ensure the safe and stable operation of power equipment.

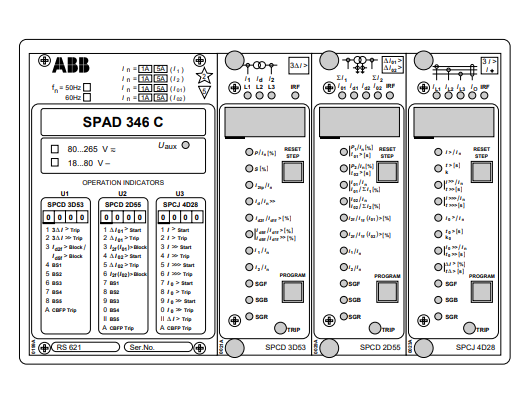

ABB SPAD346C Integrated Differential Relay

Product core positioning

ABB SPAD346C is a high-precision integrated differential relay mainly used for differential protection of transformers, generators, motors, busbars and other equipment in medium and low voltage power systems. By monitoring the difference in current on both sides of the protected equipment in real time, it quickly identifies internal short circuits, inter turn short circuits and other faults, achieves millisecond level fault removal, and has complete alarm, locking and communication functions. It is the core protection device to ensure the safe and stable operation of power equipment.

Core functions and technical parameters

1. Core protection function

Differential protection: supports ratio braking characteristics and standard product braking characteristics, and can automatically adjust the braking coefficient according to the magnitude of the fault current, avoiding misoperation in case of external faults and sensitive action in case of internal faults. The minimum operating current can be as low as 0.1In (In is the rated current), and the protection range covers all operating conditions of the equipment.

Quick break protection: When the differential current exceeds the set threshold (usually 5-10In), it can trip quickly without the need for braking judgment, with a response time of ≤ 50ms. It is suitable for emergency disconnection of severe internal short circuit faults.

Unbalanced current alarm: Real time monitoring of the imbalance of current on both sides during normal operation. When the unbalanced current exceeds the set value (such as 10% -20% In), an alarm signal is issued to indicate that the equipment may have hidden dangers such as iron core saturation and minor winding faults.

CT disconnection detection and locking: equipped with current transformer (CT) disconnection recognition function, automatically locking differential protection in case of disconnection to prevent misoperation caused by CT disconnection, and issuing CT disconnection alarm for easy troubleshooting by operation and maintenance personnel.

2. Key technical parameters

Rated current (In)

5A or 1A (can be adapted to different current levels through CT ratio setting)

Rated voltage (auxiliary power supply)

DC 24V/48V/110V/220V; AC 110V/220V/380V (wide voltage design, suitable for different power supply systems)

Differential protection action time

Fault within the area: ≤ 50ms (quick break), ≤ 100ms (ratio braking); Fault outside the area: Reliable but not functioning

Communication interface

RS485 (Modbus RTU protocol), supports real-time communication with the backend monitoring system, uploads protection action records, alarm information, and operating parameters

Measurement accuracy

Current measurement error ≤ 0.5%, differential current calculation error ≤ 1%, ensuring the accuracy of protection settings

Working environment

Temperature: -25 ℃~+70 ℃, relative humidity: ≤ 95% (no condensation), altitude: ≤ 2000m (if exceeded, reduce capacity for use)

Protection level

Body IP40 (panel installation), terminal IP20 (requires cabinet protection)

Performance characteristics

1. High reliability and sensitivity

Adopting a dual CPU redundancy design, the main CPU is responsible for protecting logical operations, while the backup CPU monitors the status of the main CPU in real time. If the main CPU fails, the backup CPU can quickly take over the core protection function to avoid protection refusal; At the same time, through high-precision current sampling chips (sampling frequency ≥ 1kHz) and optimized filtering algorithms, harmonic interference is effectively suppressed. Even under complex working conditions (such as motor start-up and transformer excitation inrush current), fault current can be accurately distinguished from normal disturbance, ensuring the reliability and sensitivity of protection actions.

2. Flexible fixed value configuration and adaptability

Support constant value modification through panel buttons, portable programmers, or backend systems. According to the type of protected equipment (such as transformers, motors), capacity, and system parameters, parameters such as differential quick break current, ratio braking coefficient, CT ratio, alarm threshold, etc. can be flexibly set without the need to replace hardware to adapt to different application scenarios; In addition, it has the function of "automatic tracking of CT ratio". When the CT ratio of the system is adjusted, the relay can automatically match, reducing the workload of manual re adjustment.

3. Comprehensive fault recording and diagnostic functions

Equipped with a large capacity storage module, it can record the last 100 protection action events (including detailed parameters such as action time, fault current, differential current, braking current, etc.) and 50 alarm events, with an event recording accuracy of milliseconds, making it easy to trace and analyze faults; At the same time, it has a self checking function to monitor the internal power supply of the relay in real time CPU、 If any abnormalities are found in the status of components such as the sampling circuit and outlet circuit (such as power failure or open circuit of the sampling circuit), immediately issue a device fault alarm to prompt the operation and maintenance personnel to handle it in a timely manner.

4. Convenient human-computer interaction and operation and maintenance

Equipped with a 128 × 64 dot matrix LCD display screen, supporting Chinese/English interface switching, it can intuitively display real-time operating parameters (such as current on both sides, differential current, unbalanced current), protection settings, event records, and alarm information; The panel is equipped with reset, test, and constant value switching buttons, which are easy to operate and can complete daily maintenance without the need for professional tools; In addition, it supports the "offline simulation testing" function, which can verify the correctness of the protection logic by simulating fault signals without connecting to the actual current circuit, reducing the risk of on-site debugging.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-