Product type: Industrial grade grounding fault protection relay (belonging to ABB SPAJ series, focusing on grounding fault detection and protection of low-voltage distribution systems, suitable for TT, TN-S and other grounding systems)

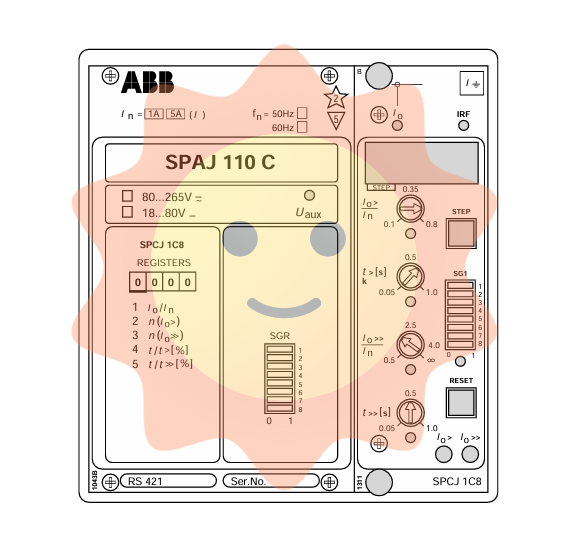

Model identification: SPAJ110 C (product series code, "C" represents basic protection type, with standard grounding fault protection function), no separate globally unique code (usually marked with the distribution equipment as a whole, model+specification parameters need to be provided when purchasing separately)

Physical specifications: Designed with DIN rail installation, the dimensions are 90mm (width) x 75mm (height) x 120mm (depth), with a net weight of 0.35kg. It is suitable for compact layouts of low-voltage distribution cabinets and distribution boxes and can be installed in conjunction with circuit breakers, contactors, and other equipment.

ABB SPAJ110C Earth-fault relay

Core positioning and basic parameters of the product

1. Core attributes

Product type: Industrial grade grounding fault protection relay (belonging to ABB SPAJ series, focusing on grounding fault detection and protection of low-voltage distribution systems, suitable for TT, TN-S and other grounding systems)

Model identification: SPAJ110 C (product series code, "C" represents basic protection type, with standard grounding fault protection function), no separate globally unique code (usually marked with the distribution equipment as a whole, model+specification parameters need to be provided when purchasing separately)

Physical specifications: Designed with DIN rail installation, the dimensions are 90mm (width) x 75mm (height) x 120mm (depth), with a net weight of 0.35kg. It is suitable for compact layouts of low-voltage distribution cabinets and distribution boxes and can be installed in conjunction with circuit breakers, contactors, and other equipment.

2. Key electrical and performance parameters

Power supply demand

AC 230V ± 15%/DC 24V ± 20%, rated power consumption ≤ 5VA (AC)/≤ 3W (DC)

Adapt to commonly used industrial power supply methods, it is recommended to synchronize power supply with the main power supply of the distribution system to ensure the continuous effectiveness of protection functions

Ground fault detection

Detection current range: 30mA -10A (adjustable through dip switch or knob), action time: 0.1s -30s (adjustable)

Covering the common grounding fault current range of low-voltage systems, the action time can be flexibly set according to system requirements, taking into account both protection sensitivity and selectivity

Input signal interface

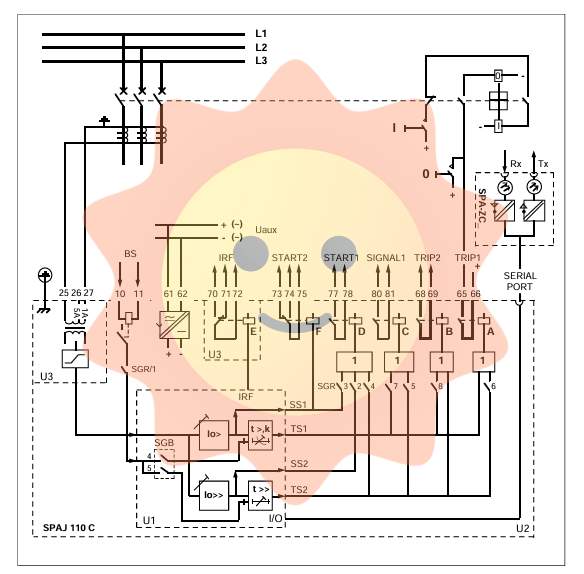

1 current transformer (CT) input (rated input 5A/1A, to match on-site CT specifications), 1 fault reset input (passive contact)

The grounding current signal needs to be collected through a dedicated current transformer, and the reset input supports manual or automatic reset of the fault state

Output contact

2 sets of normally open auxiliary contacts (capacity AC 250V/5A, DC 24V/3A), 1 set of fault alarm contacts (passive, with the same capacity as the auxiliary contacts)

Auxiliary contacts can be used to control circuit breaker tripping and activate alarm devices; The alarm contact can be connected to indicator lights, sound and light alarms, etc

Working environment

Temperature -25 ℃ to+60 ℃, humidity 5% -95% (no condensation), protection level IP40 (module body)

To adapt to industrial site environments with high and low temperatures and high humidity, it needs to be installed inside enclosed power distribution equipment to avoid direct contact with dust and water vapor

Core functions and technological advantages

1. Precise grounding fault detection and protection

Multi detection principle support: Using the "residual current detection method", the three-phase current vector sum (ground fault current) is collected through a current transformer. When the current exceeds the set threshold, the protection action is quickly triggered; Support "high resistance grounding fault detection", which can detect grounding faults with a resistance value ≤ 10k Ω (suitable for scenarios where high resistance grounding is prone to occur such as humidity and dust), avoiding the risk of traditional relays being missed.

Classification protection function: It has the dual action characteristics of "timed limit+inverse time limit". For small current grounding faults (such as 30mA-1A), inverse time limit action is adopted (the larger the fault current, the shorter the action time), and for large current grounding faults (such as 1A-10A), timed limit action is adopted (fixed action time, ensuring quick fault cutting), meeting the "selective protection" requirements of the distribution system and avoiding the expansion of faults leading to large-scale power outages.

2. High reliability and anti-interference design

Fault self diagnosis: Real time monitoring of self power supply, current transformer input, and contact status. When faults such as power supply abnormality, CT disconnection, and contact adhesion occur, an alarm is triggered through a red fault indicator light, and the protection output is locked to prevent misoperation or refusal to operate; Support fault state memory, which needs to be manually reset after troubleshooting to facilitate tracing the cause of the fault.

Anti interference performance: Compliant with the IEC 61000-6-4 industrial anti-interference standard, the anti-interference level of electromagnetic compatibility (EMC) reaches level 3, which can resist electromagnetic interference generated by motor start stop and frequency converter operation in low-voltage systems, ensuring accurate detection data and reliable protection actions in complex electromagnetic environments.

Overload and Short Circuit Tolerance: The input circuit is equipped with overload protection (capable of withstanding 10 times the rated input current for 1 second) and short circuit protection (capable of withstanding 20 times the rated input current for 0.1 second) to prevent damage to the internal circuit of the relay due to secondary side short circuit or excessive fault current of the current transformer.

3. Flexible configuration and ease of use

Convenient parameter adjustment: The grounding fault current threshold and action time can be directly adjusted through the dip switch or knob on the panel, without the need for dedicated software. On site debugging personnel can quickly complete the configuration; The panel is equipped with green operation indicator light and red fault indicator light, which intuitively displays the working status (operation/fault) of the relay.

Compatible with multiple grounding systems: Supports TT systems (direct grounding of power neutral point, separate grounding of exposed conductive parts of equipment), TN-S systems (direct grounding of power neutral point, connection of exposed conductive parts of equipment to neutral point through protective wire), and can adapt to the protection needs of different grounding systems through simple parameter settings without the need for hardware replacement.

Extended function support: Reserve 1 communication interface (optional RS485 module, supporting Modbus RTU protocol), which can be connected to the distribution monitoring system to achieve remote collection and monitoring of grounding fault data (fault current value, action time); Support linkage with ABB low-voltage circuit breakers (such as Tmax series), directly controlling circuit breaker tripping through auxiliary contacts, simplifying system wiring.

Application scenarios and system compatibility

1. Typical application areas

Industrial low voltage distribution system: used as a low voltage distribution cabinet in factory workshops and production lines to protect equipment such as motors, frequency converters, PLCs, etc. from damage caused by grounding faults, such as the grounding fault protection of machine tool equipment power supply circuits, fan and water pump distribution circuits, to avoid equipment burnout or personnel electric shock accidents.

Commercial building power distribution: Suitable for low-voltage power distribution systems in office buildings, shopping malls, and hotels, protecting the grounding safety of lighting circuits, air conditioning systems, and elevator equipment, such as detecting grounding faults in shopping mall lighting circuits (to prevent grounding leakage caused by aging and humidity of the lines, which may lead to fire risks).

Civil building power distribution: used as a distribution box in residential communities and villas to protect the grounding safety of household electrical equipment (such as refrigerators, air conditioners, water heaters), especially suitable for TN-S grounding system household power distribution. When the equipment shell leaks electricity, the power supply is quickly cut off to ensure personal safety.

Special Industry Distribution: Suitable for industries with high electrical safety requirements such as chemical, food processing, and pharmaceutical industries, such as explosion-proof distribution circuits in chemical workshops (requiring explosion-proof current transformers) and humid environment distribution circuits in food processing workshops (high resistance grounding fault detection function can effectively avoid missed diagnosis).

2. Key points of system integration

Wiring specification: The secondary side of the current transformer (CT) should be separately wired to the relay input terminal, and it is prohibited to share the CT secondary circuit with other devices; The CT polarity needs to be connected correctly (with the "P1" end facing the power supply side and the "P2" end facing the load side), otherwise it will cause ground current detection errors and protection action failure.

Parameter matching: Set the relay grounding system parameters according to the grounding type of the distribution system (TT/TN-S). For example, the TT system needs to set the grounding fault current threshold to 300mA-10A (due to the high grounding resistance of the TT system, the fault current is small), while the TN-S system can be set to 30mA-5A (due to the high fault current, higher sensitivity is required).

Linkage control: If it is linked with the circuit breaker, the relay output contact should be connected to the circuit breaker trip coil, and the circuit breaker auxiliary contact (normally closed) should be connected in series in the circuit to ensure the continuity of the protection circuit when the circuit breaker is closed; The alarm contact can be connected to an audible and visual alarm, which can promptly alert on-site personnel to handle any malfunctions.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-