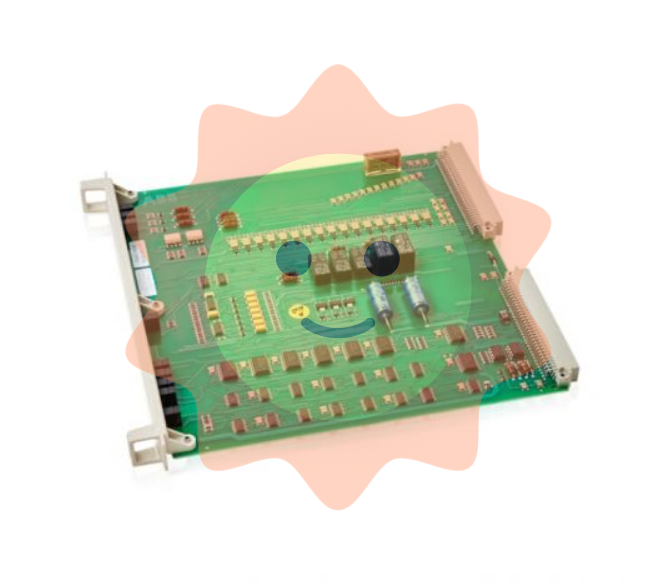

Product type: High performance industrial process control and logic control integrated controller (belonging to ABB T series high-end product line, focusing on high-precision control requirements of large discrete manufacturing and complex process industries, with multi task concurrent processing, high reliability redundancy design, suitable for core control nodes of large automation systems)

Model identification: T-1521Z ("T" is the series code, representing high-end and high-performance; 1521 "is a specification code that distinguishes between processing performance and I/O expansion capability; Z "represents enhanced redundancy and anti-interference design, suitable for key industrial scenarios

Physical specifications: Adopting a 4U rack mounted design, the dimensions are 482.6mm (width, compatible with 19 inch standard cabinets) x 177.8mm (height) x 305mm (depth), with a net weight of 5.2kg. It supports front and rear ventilation and heat dissipation, and can be installed in conjunction with ABB high-end I/O modules (such as AI890, AO890) and redundant power modules (such as SD850) to meet the requirements of high-density system deployment.

ABB T-1521Z High-Performance Industrial Controller

Core attributes

Product type: High performance industrial process control and logic control integrated controller (belonging to ABB T series high-end product line, focusing on high-precision control requirements of large discrete manufacturing and complex process industries, with multi task concurrent processing, high reliability redundancy design, suitable for core control nodes of large automation systems)

Model identification: T-1521Z ("T" is the series code, representing high-end and high-performance; 1521 "is a specification code that distinguishes between processing performance and I/O expansion capability; Z "represents enhanced redundancy and anti-interference design, suitable for key industrial scenarios

Physical specifications: Adopting a 4U rack mounted design, the dimensions are 482.6mm (width, compatible with 19 inch standard cabinets) x 177.8mm (height) x 305mm (depth), with a net weight of 5.2kg. It supports front and rear ventilation and heat dissipation, and can be installed in conjunction with ABB high-end I/O modules (such as AI890, AO890) and redundant power modules (such as SD850) to meet the requirements of high-density system deployment.

Key electrical and performance parameters

Power supply demand

Dual DC 24V ± 10% redundant input, rated power consumption of 35W, maximum power consumption of 50W (full load operation+redundant backup)

Must be paired with ABB SD850 redundant power module, supporting seamless power failure switching (switching time ≤ 5ms), ensuring uninterrupted core control

Control signal interface

Built in 16 high-speed analog inputs (AI, 4-20mA/0-10V/PT100/PT1000, 24 bit resolution), 8 high-precision analog outputs (AO, 4-20mA, accuracy ± 0.05%), 32 high-speed digital inputs (DI, 24V DC, photoelectric isolation, response time ≤ 0.1ms), and 16 high-power digital outputs (DO, 24V DC/5A, relay+transistor dual output mode)

Covering high-precision and high-speed signal acquisition and control requirements, AI supports low-temperature drift (≤ 5ppm/℃), DI supports high-speed pulse counting (up to 1MHz), and is suitable for servo motor positioning, high-speed flow measurement and other scenarios

Processing performance

Dual core 32-bit industrial grade CPU (ARM Cortex-A9, clock speed 1GHz), computing speed of 1500 MIPS, program storage capacity of 128MB (Flash, supports online expansion to 512MB), data storage capacity of 64MB (RAM, supports DDR3 expansion to 256MB)

Supports 32 independent PID loops, 8 cascaded PID loops, and 4 fuzzy control loops, and can run the full range of IEC 61131-3 programming languages (including structured text ST and sequential function diagram SFC) to meet the requirements of complex process control (such as multivariable coupling control and advanced process control APC)

Communication interface

4 Gigabit Ethernet interfaces (supporting Modbus TCP, EtherNet/IP, Profinet IRT), 2 RS485/RS232 switching interfaces (supporting Modbus RTU/ASCII, DF1), 2 Profibus DP/PA master interfaces, and 1 industrial Ethernet redundant interface (supporting PRP/HSR redundant protocols)

Full protocol coverage+redundant communication design, Gigabit Ethernet supports real-time data transmission (latency ≤ 1ms), PRP/HSR protocol ensures communication link failure without packet loss switching, suitable for distributed control and remote monitoring of large systems

Working environment

Temperature -40 ℃ to+75 ℃, humidity 5% -95% (no condensation, supports condensation environment operation), protection level IP21 (module body), anti electromagnetic interference level IEC 61000-6-2 (level 4+, enhanced)

Extreme environmental adaptability, able to withstand extreme cold (such as equipment control at Arctic scientific research stations), high temperature (such as around metallurgical blast furnaces), and strong electromagnetic interference (such as high-voltage frequency converter cluster environment), meeting the continuous operation needs of key industries 24/7

Core functions and technological advantages

1. High performance control and signal processing capabilities

Advanced control algorithm integration: built-in standard PID, cascade PID, fuzzy PID, predictive control, adaptive control and other algorithms, PID control cycle can be as low as 10ms, control accuracy error ≤ 0.02%, support multivariable decoupling control (such as temperature pressure liquid level three variable coupling adjustment in chemical reaction kettle), solve the problem of parameter interference in complex processes; Support custom algorithm development (based on C/C++language), adapted to the customized control needs of special industries (such as aerospace component manufacturing).

High speed signal acquisition and processing: The AI channel uses a 24 bit Delta Sigma analog-to-digital conversion chip, combined with hardware filtering (configurable 0.1-1000Hz filtering frequency) and software digital filtering, to achieve precise acquisition of microvolt level signals (such as capturing small changes in sensors); The DI channel supports high-speed pulse counting and frequency measurement (up to 1MHz), and can be directly connected to encoder signals to achieve closed-loop control of servo motor position (such as high-precision CNC machine tool axis positioning), without the need for additional pulse modules.

Multi task concurrent processing: Based on real-time operating system (RTOS), it supports scheduling 128 priority tasks. Core control tasks (such as PID tuning) have the highest priority, while non core tasks (such as data storage and logging) are automatically downgraded to ensure that critical control is not affected by non core tasks; Support data sharing and synchronization between tasks, avoid multi task conflicts, and meet the needs of collaborative control of multiple devices in large-scale systems (such as multi robot linkage in automotive welding production lines).

2. Full dimensional redundancy and high reliability design

Triple redundancy architecture: supports power redundancy (dual power hot standby), CPU redundancy (synchronous operation of primary and backup CPUs, fault switching time ≤ 10ms), and communication redundancy (PRP/HSR protocol+dual network port backup), achieving "fault insensitive switching", suitable for critical scenarios such as petrochemicals and nuclear power that require "zero interruption" for system continuity; The I/O module supports hot swapping, so there is no need to shut down when replacing the module, and the maintenance process does not affect the system operation.

Fault self diagnosis and predictive maintenance: With three-level diagnostic functions (module level, channel level, component level), it can monitor CPU temperature, power supply voltage, communication link quality, I/O channel status in real time, and even predict the life of key components (such as capacitors and relays) (based on running time and stress analysis), and send maintenance warnings in advance through the upper computer; Fault information is uploaded using standardized protocols (such as IEC 61850), supporting remote fault location and diagnosis, reducing on-site troubleshooting time.

Extreme environmental protection: using wide temperature industrial grade components (working temperature -40 ℃ to+125 ℃) and conformal coating three proof coating process (moisture-proof, anti salt spray, anti-corrosion), it can operate for a long time in harsh environments such as offshore platforms (high salt spray), underground mines (high dust), desert areas (extreme temperature difference), etc; The anti vibration level complies with IEC 60068-2-6 (10-2000Hz, 15g), and the anti impact level complies with IEC 60068-2-27 (50g, 11ms), suitable for vibration and impact scenarios of transportation equipment (such as rail vehicle control systems).

3. Flexible expansion and intelligent integration

I/O Expansion Capability: Supports remote I/O module expansion through Profinet IRT and Profibus DP, with a maximum expansion of 1024 AI, 512 AO, 2048 DI, and 1024 DO channels, suitable for distributed signal acquisition requirements in large systems; The expansion module supports plug and play, automatically identifying module types and addresses without manual configuration, simplifying the system expansion process.

Industrial Internet integration: built-in edge computing function, supporting data pre-processing (such as filtering, aggregation, anomaly detection) and uploading to industrial cloud platforms (such as ABB Ability ™ Reduce cloud data transmission volume and latency through cloud and third-party cloud platforms such as AWS/Azure; It supports MQTT, OPC UA and other industrial Internet protocols, can interface with the intelligent manufacturing execution system (MES) and enterprise resource planning system (ERP), realize the data connection of "control production management", and help the construction of intelligent factories.

Safety control function: compliant with IEC 61508 safety standard (SIL 3 certification), with built-in safety logic controller (SLC) function, which can achieve safety interlock control (such as emergency shutdown ESD, safety door monitoring), without the need for additional safety controllers; The safety signal adopts dual verification of hard wiring and software to ensure that the safety function does not fail, and is suitable for industries such as chemical and pharmaceutical industries that have extremely high requirements for safety production.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-