Product type: Compact industrial process control module (belonging to ABB TAS 580 series, focusing on lightweight parameter acquisition and logic control for small and medium-sized process industries, suitable for nodes with moderate I/O requirements in distributed control scenarios)

Model identification: TAS.580.0550G00 ("TAS" is the series code, "580" represents high-performance control level, and "0550G00" is the specification code. Compared to 0560G00, it focuses on optimizing I/O resource allocation and adapting to medium-sized signal processing requirements)

Physical specifications: Continuing the 3U rack design, the dimensions are 160mm (width) x 130mm (height) x 260mm (depth), with a net weight of 1.6kg, slightly thinner and lighter than 0560G00, suitable for space limited control cabinet layouts, and supports stacking installation with power modules and extended I/O modules of the same series.

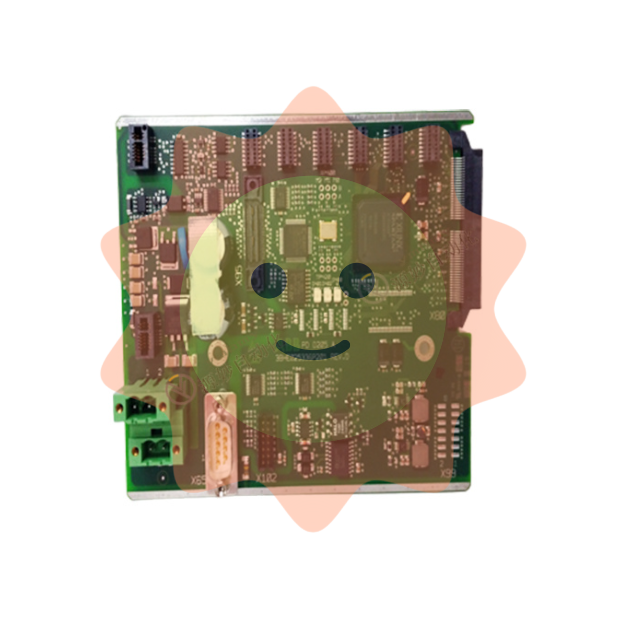

ABB TAS.580.0550G00 Industrial Controller Module

Core positioning and basic parameters of the product

1. Core attributes

Product type: Compact industrial process control module (belonging to ABB TAS 580 series, focusing on lightweight parameter acquisition and logic control for small and medium-sized process industries, suitable for nodes with moderate I/O requirements in distributed control scenarios)

Model identification: TAS.580.0550G00 ("TAS" is the series code, "580" represents high-performance control level, and "0550G00" is the specification code. Compared to 0560G00, it focuses on optimizing I/O resource allocation and adapting to medium-sized signal processing requirements)

Physical specifications: Continuing the 3U rack design, the dimensions are 160mm (width) x 130mm (height) x 260mm (depth), with a net weight of 1.6kg, slightly thinner and lighter than 0560G00, suitable for space limited control cabinet layouts, and supports stacking installation with power modules and extended I/O modules of the same series.

2. Key electrical and performance parameters

Power supply demand

DC 24V ± 10%, rated power consumption of 10W, maximum power consumption of 15W (during full load operation)

Compatible with ABB SD800 series regulated power supply, with power consumption about 17% lower than 0560G00, more suitable for low-power scenarios. It is recommended to reserve a 20% power margin

Control signal interface

12 analog inputs (AI, 4-20mA/0-10V optional, no PT100 direct input), 6 analog outputs (AO, 4-20mA), 12 digital inputs (DI, 24V DC, optoelectronic isolation), 6 digital outputs (DO, 24V DC/2A, relay output)

The number of I/O points has decreased by about 25% compared to 0560G00, and PT100 dedicated channels have been removed to focus on standard industrial signal processing, balancing cost and functionality

Processing performance

32-bit RISC processor with a processing speed of 120 MIPS, program storage capacity of 32MB (Flash), and data storage capacity of 16MB (RAM)

The computation speed is slightly lower than 0560G00, but it still supports 6 independent PID loops, meeting the requirements of medium complexity logic computation and real-time control

Communication interface

2 Ethernet (TCP/IP) interfaces (supporting Modbus TCP, EtherNet/IP), 1 RS485 (Modbus RTU) interface, 1 Profibus DP slave interface

Remove one RS485 interface, retain support for core industrial communication protocols, and adapt to small and medium-sized systems with non redundant communication architectures

Working environment

Temperature -25 ℃ to+70 ℃, humidity 5% -95% (no condensation), protection level IP20 (module body), anti vibration level IEC 60068-2-6 (5-500Hz, 10g)

The environmental adaptability is completely consistent with 0560G00, and the installation space of the control cabinet can be shared without the need for additional protective measures

Core functions and technological advantages

1. Balanced process control capability

Simplified algorithm integration: Built in standard PID and cascade control algorithms, PID control accuracy error ≤ 0.1% (slightly lower than 0.05% of 0560G00), supports adjustment of core parameters such as temperature and pressure, such as liquid level flow cascade control for small storage tanks (AI collects liquid level signals, AO adjusts feed valve opening).

Signal processing optimization: Analog input supports hardware filtering (adjustable filtering frequency 1-100Hz) and software calibration. Although there is no PT100 direct input, temperature signals can be indirectly collected through an external temperature transmitter (4-20mA output), which is compatible with mainstream temperature measurement scenarios; The anti shake time for digital input is 5ms, consistent with 0560G00.

Loop control adaptability: Supports 6 independent PID loops or 3 cascaded PID loops, and can be configured with simple interlocking logic through software (such as pump start stop sequence control) to meet the collaborative regulation requirements of non high precision processes without the need for additional control module expansion.

2. High reliability and practical design

Fault protection mechanism: Supports power redundancy (requires dual power modules), with a switching time of ≤ 5ms; has module level self diagnostic function, can monitor processor, I/O interface and communication status, and alarm through indicator lights and communication protocol in case of faults. The diagnostic range is consistent with 0560G00.

Anti interference performance: compliant with IEC 61000-6-2 standard, ESD, RFI, EFT anti-interference level 4, shared anti-interference design with 0560G00, can resist electromagnetic interference generated by frequency converters, motors and other equipment, ensuring signal acquisition stability.

Power failure data protection: Flash program storage+supercapacitor data backup (maintained for 72 hours after power failure), automatic restart after power restoration, data protection mechanism fully compatible with 0560G00, ensuring control program continuity.

3. Lightweight system integration characteristics

Multi system compatibility: It can seamlessly integrate with ABB 800xA and Freelance control systems, support communication with third-party software such as Siemens WinCC and Rockwell FactoryTalk, and is compatible with the 0560G00 communication protocol stack, making it easy to integrate mixed configuration systems.

Convenience of configuration and debugging: It also supports ABB Control Builder M software graphical programming (IEC 61131-3 standard), with built-in simplified control templates (such as single loop PID, basic logic interlocking). During debugging, it can monitor input and output values, CPU usage, and other parameters in real time, and support online configuration modification.

Maintenance friendliness: Modular plug-in design, I/O and communication interfaces can be disassembled separately, module replacement time ≤ 15 minutes (faster than 0560G00); The panel is equipped with three color indicator lights for operation, fault, and communication, and the status recognition is consistent with 0560G00, reducing the cost of operation and maintenance learning.

Application scenarios and system compatibility

1. Typical application areas

Small and medium-sized manufacturing industry: used for auxiliary system control of mechanical processing production lines, such as temperature regulation of CNC machine tool cooling system (AI collects water temperature, AO controls cooling pump speed), workshop ventilation air pressure control (DI monitors fan status, DO controls fan start stop), suitable for medium-sized signal processing needs.

Small food processing line: suitable for key parameter control of baking equipment and small filling lines, such as oven temperature regulation (converted to 4-20mA signal input through temperature transmitter, AO controls heating tube power), material conveying flow control (AI collects flow signal, AO adjusts conveying pump speed), balancing cost and control accuracy.

Small water treatment unit: suitable for village and town level sewage treatment stations, industrial circulating water systems, controlling pH value adjustment (AI collects pH sensor signals, AO controls dosing valve opening), filter backwash logic (DI monitors pressure difference, DO controls backwash valve), without redundant I/O resources.

Building intelligent control: used for air conditioning and water supply and drainage system control in commercial buildings, such as temperature regulation of floor air conditioning (AI collects room temperature, AO controls regulating valves), rotation control of water pump groups (DI monitors pressure, DO controls water pump start and stop), suitable for lightweight building automation scenarios.

2. Key points of system integration

Wiring specification: The analog signal adopts shielded twisted pair cable, and the shielding layer is grounded at one end (grounding resistance ≤ 4 Ω); Due to the reduction in DO points, contactor expansion should be prioritized when controlling high-power equipment, and a 1N4007 freewheeling diode should be connected in parallel at the output end to suppress reverse electromotive force.

Communication configuration: The Ethernet interface is configured with a fixed IP and is on the same network segment as the upper computer, with a 25% reserved communication bandwidth; The Profibus DP bus terminal is equipped with a 120 Ω resistor to avoid conflicts with other devices at the slave station address, and the communication delay can be controlled within ≤ 30ms (slightly higher than 0560G00).

Power configuration: A single power supply can meet the requirements. If redundancy is needed, a dual power diode isolation scheme can be used; The distance between power cables and signal cables should be ≥ 8cm to reduce interference (due to lower power consumption, the interference sensitivity is slightly lower than 0560G00).

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-