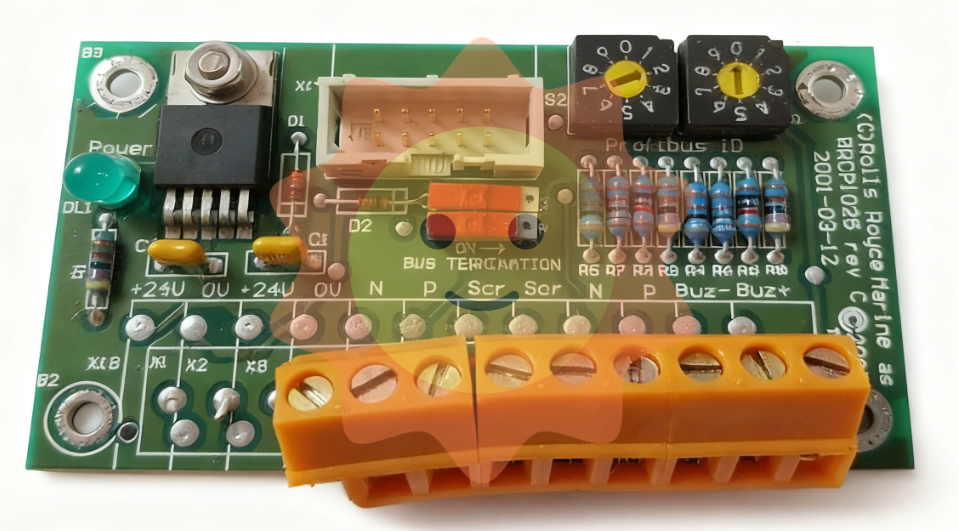

Rolls-Royce Thruster Panel - FAST SHIP BY DHL/FEDEX

The Rolls-Royce Thruster Panel stands as a pinnacle of engineering excellence within Rolls-Royce automation products, specifically designed to meet the rigorous demands of the power industry, petrochemical sector, and general automation environments. Engineered for precision, reliability, and robust performance, the Thruster Panel integrates advanced control technologies with superior durability to provide unparalleled operational efficiency. At its core, the Rolls-Royce Thruster Panel features a high-capacity input/output architecture capable of managing complex control signals with lightning-fast response times. Supporting both analog and digital inputs, the panel can handle up to 128 I/O channels, enabling comprehensive monitoring and control of thruster operations, propulsion systems, and auxiliary equipment. Its modular design ensures seamless scalability and ease of integration with existing control networks, including compatibility with Rolls-Royce’s proprietary communication protocols. Built with industrial-grade components, the Thruster Panel is rated for operation in harsh environments, offering resistance to extreme temperatures, humidity, and vibrations commonly encountered in offshore and petrochemical installations.

The panel’s performance metrics include a mean time between failures (MTBF) exceeding 50,000 hours, ensuring dependable service continuity even in mission-critical applications. In real-world scenarios, the Rolls-Royce Thruster Panel excels in dynamic environments where precise thrust control is essential. For example, in offshore power plants, the panel governs thruster motors with exacting precision to stabilize platforms and maintain positioning during complex operations. In petrochemical facilities, it facilitates smooth automation of valve actuation and pump controls, integrating seamlessly with broader plant management systems to optimize throughput and safety. The panel’s adaptive control algorithms also enhance vessel maneuverability in marine automation, providing real-time adjustments that improve fuel efficiency and reduce wear on propulsion components. These capabilities make the Thruster Panel indispensable in applications where accuracy, reliability, and rapid responsiveness are non-negotiable. Comparatively, the Rolls-Royce Thruster Panel distinguishes itself from other models within the Rolls-Royce product family through its specialized focus on thruster control and its superior I/O capacity. While models like the Rolls-Royce MPC200 and MPC-210 offer versatile automation solutions across multiple platforms, the Thruster Panel’s design prioritizes thrust-specific feedback loops and fail-safe mechanisms that are critical for propulsion management.

Unlike the Rolls-Royce HCX CONTROL LEVER, which provides manual control inputs for auxiliary systems, the Thruster Panel automates these controls, reducing human error and increasing operational efficiency. Additionally, the panel’s compatibility with Rolls-Royce SLIO-02 and CANMAN SLIO 02 modules allows for enhanced networked control, surpassing the standalone capabilities of simpler control units such as the Rolls-Royce CE02-01. Alongside the Rolls-Royce Thruster Panel, complementary automation products such as the Rolls-Royce en-tronic ft-110 and Rolls-Royce PCC1030C AND LKI1032 offer advanced signal processing and interface options, expanding the scope of automation solutions available for complex installations. The inclusion of the Rolls-Royce MPCF1-10.4" touchscreen interface further enhances user interaction with the Thruster Panel, providing intuitive visualization and control capabilities. For environments demanding rigorous safety protocols, integration with the Rolls-Royce BPCS-0401N-001 safety controller ensures compliance with industry standards, while the Rolls-Royce FMV 25B valve module optimizes fluid control in petrochemical applications. The Rolls-Royce 5880-PC1019 and 5880-PC1020 REV.C models complement the Thruster Panel’s functionality by offering precise power conditioning and distribution control, essential for maintaining system stability.

The application of the Rolls-Royce Thruster Panel in the power industry, petrochemical, and general automation sectors highlights its versatility and engineering sophistication. Whether stabilizing offshore platforms in turbulent sea conditions, automating critical valves and pumps in chemical processing plants, or enhancing propulsion control in marine vessels, the Thruster Panel delivers unmatched performance and reliability. Its seamless integration with other Rolls-Royce automation products ensures that operators can build comprehensive, scalable, and future-proof systems tailored to their specific operational demands. In summary, the Rolls-Royce Thruster Panel is a highly specialized and robust control solution engineered to meet the demanding requirements of modern industrial automation. Boasting expansive I/O capacity, durable construction, and cutting-edge control algorithms, it stands out within the Rolls-Royce portfolio, offering unique advantages over models such as the MPC200, HCX CONTROL LEVER, and SLIO-02. When paired with complementary devices like the en-tronic ft-110, PCC1030C AND LKI1032, MPCF1-10.4", and BPCS-0401N-001, it forms the backbone of reliable and efficient automation systems. For organizations seeking superior control and automation in the power, petrochemical, and general automation arenas, the Rolls-Royce Thruster Panel represents an unrivaled choice

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-