ALSTOM VCM 232.2 029.359 088 VME-MANAGER-MASTER 0085.022.99 Module (hereinafter referred to as "VME Management Master Module") is a core control module developed by Alstom specifically for industrial automation and rail transit control systems. Based on the VME bus technology architecture, it undertakes key tasks such as system resource management, data exchange scheduling, and equipment collaborative control. As the "main controller" in the VME bus system, this module provides a stable control core for complex industrial scenarios with high reliability, strong real-time performance, and flexible expansion capabilities. It is widely used in fields such as rail transit signal systems and industrial process control that require strict equipment stability and control accuracy. Its integrated design not only simplifies system wiring, but also achieves seamless compatibility with Alstom's full range of supporting equipment through standardized interfaces, effectively improving the overall system's operation and maintenance efficiency and fault handling capabilities.

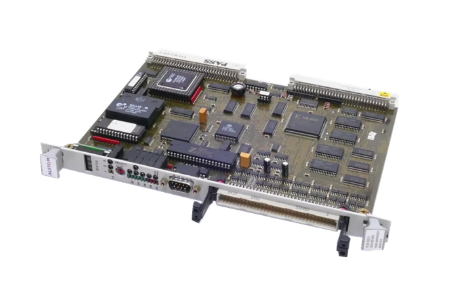

ALSTOM VCM 232.2 029.359 088 VME-MANAGER-MASTER 0085.022.99 Module

Product Overview

ALSTOM VCM 232.2 029.359 088 VME-MANAGER-MASTER 0085.022.99 Module (hereinafter referred to as "VME Management Master Module") is a core control module developed by Alstom specifically for industrial automation and rail transit control systems. Based on the VME bus technology architecture, it undertakes key tasks such as system resource management, data exchange scheduling, and equipment collaborative control. As the "main controller" in the VME bus system, this module provides a stable control core for complex industrial scenarios with high reliability, strong real-time performance, and flexible expansion capabilities. It is widely used in fields such as rail transit signal systems and industrial process control that require strict equipment stability and control accuracy. Its integrated design not only simplifies system wiring, but also achieves seamless compatibility with Alstom's full range of supporting equipment through standardized interfaces, effectively improving the overall system's operation and maintenance efficiency and fault handling capabilities.

Specification parameters

2.1 Basic Parameters

-Product model: VCM 232.2; Accessory number: 029.359 088, 0085.022.99

-Product type: VME bus management main module

-Bus standard: Compliant with VMEbus Rev. C. specification, supports 32-bit data/address bus

-Size specifications: Standard VME rack size, height 3U (132.3mm), depth 220mm, width 160mm (compatible with standard 19 inch cabinets)

-Weight: Approximately 1.8kg

2.2 Electrical Parameters

-Power supply voltage: DC+5V ± 5%,+12V ± 10%, -12V ± 10%, supports wide voltage adaptation

-Working current: maximum 8A at+5V, maximum 1.5A at+12V, maximum 0.5A at -12V

-Power consumption: Typical power consumption of 45W, maximum power consumption of 60W

-Insulation resistance: ≥ 100M Ω (500V DC) between the power terminal and the ground terminal

-Anti interference performance: Complies with EN 55022 Class A electromagnetic compatibility standard, with surge resistance of ± 2kV (line to line) and ± 4kV (line to ground)

2.3 Interface Parameters

-VME interface: 1 standard VME bus interface, supporting bus arbitration and interrupt handling

-Serial interface: 2 optional RS-232/RS-485 interfaces, baud rate range 9600bps-115200bps, supporting parity check

-Ethernet interface: 2 10/100Mbps adaptive Ethernet ports, supporting TCP/IP, UDP protocols, RJ45 interface

-Digital I/O: 8 inputs/8 outputs, input voltage 0-30V DC, output maximum load current 1A

-Debugging interface: 1 JTAG debugging interface, supporting firmware upgrade and fault diagnosis

2.4 Environmental Parameters

-Working temperature: -25 ℃~+70 ℃ (wide temperature range, suitable for harsh industrial environments)

-Storage temperature: -40 ℃~+85 ℃

-Relative humidity: 5%~95% (no condensation)

-Vibration level: Complies with IEC 60068-2-6 standard, 10Hz-500Hz, acceleration 5g

-Impact level: Complies with IEC 60068-2-27 standard, peak acceleration 20g, duration 11ms

Performance characteristics

3.1 High reliability main control capability

The module is equipped with a high-performance 32-bit embedded processor with a clock frequency of up to 200MHz, which has powerful data processing capabilities and supports real-time multitasking scheduling. The task response time is ≤ 1ms, ensuring real-time control and data processing of bus devices. Adopting a dual redundancy design, supporting automatic switching between primary and backup with a switching time of less than 50ms, effectively avoiding system interruptions caused by single point failures and meeting the high availability requirements of industrial control systems.

3.2 Flexible Bus Management and Expansion

As the main module of VME bus management, it supports bus arbitration and resource allocation for up to 16 slave devices, and can dynamically adjust bus bandwidth and device priority according to system requirements. Compatible with Alstom's full range of VME slave modules (such as IO modules, communication modules, acquisition modules, etc.), while supporting third-party device access that complies with VME specifications, it has strong scalability and can adapt to control systems of different scales.

3.3 Comprehensive fault diagnosis and protection

Equipped with a comprehensive self diagnostic mechanism, it can monitor the module's power supply status, processor operation status, bus communication status, and interface connection status in real time. Fault information is uploaded to the monitoring system in real time through Ethernet or serial interface, and displayed intuitively on the module panel LED indicator lights (such as power light, operation light, fault light). It has overcurrent, overvoltage, and short-circuit protection functions. When the power supply is abnormal or the interface load exceeds the standard, it automatically cuts off some non core circuits to protect the core components of the module from damage.

3.4 Strong environmental adaptability

Adopting industrial grade wide temperature element devices and sealed dust-proof design, it can work stably in harsh environments such as high and low temperatures, high humidity, vibration, electromagnetic interference, etc., meeting the needs of complex scenarios such as rail transit and industrial sites. The surface of the module adopts a heat dissipation coating, combined with an optional built-in heat dissipation fan, to ensure timely dissipation of heat in high temperature environments and maintain stable operation of the equipment.

3.5 Convenient operation and upgrade

Support firmware upgrade and parameter configuration remotely through Ethernet, without the need for on-site module disassembly, reducing operation and maintenance costs. Provide standardized communication protocols and development interfaces (such as API libraries and Modbus protocol) for easy integration with upper computer monitoring systems (such as SCADA systems), enabling centralized monitoring and data management of equipment status.

Working principle

The main module of VME management is based on high-performance embedded processors and implements "master-slave" control and data interaction based on the VME bus architecture. Its workflow is mainly divided into the following steps:

1. System initialization: After the module is powered on, it first executes a self diagnostic program to detect the core circuit, interface, and bus status. After the diagnosis is passed, it loads preset configuration parameters (such as bus priority, device address, communication protocol, etc.), completes initialization, and enters the standby state, waiting for instructions from the upper computer or system.

2. Bus management and device scheduling: After receiving the startup instruction, the module acts as the bus master device and performs address scanning and identity recognition on the connected slave devices through the VME bus interface, establishes a device list, and allocates bus resources (such as address space and interrupt numbers). According to the system task requirements, the work sequence of each slave device is scheduled through the bus arbitration mechanism to ensure that high priority tasks (such as emergency stop signal processing and key parameter collection) have priority in obtaining bus control.

3. Data exchange and processing: The main module receives data uploaded by various slave devices through the VME bus (such as sensor data and device operating status data), filters, parses, and calculates it through the processor, generates control instructions, and then sends them to the corresponding slave devices through the bus (such as controlling IO modules to perform switch actions and adjust actuator parameters). At the same time, the processed data is uploaded to the upper computer monitoring system through an Ethernet interface to achieve bidirectional data exchange.

4. Status monitoring and fault handling: During the working process, the self diagnostic module monitors the real-time operation status of the module itself and its slave devices. When a fault is detected (such as bus communication interruption, slave device fault, power supply abnormality), the fault protection mechanism is immediately triggered: on the one hand, the current non core tasks are paused through a interrupt signal, and the fault is prioritized for processing; On the other hand, the fault information is encoded and uploaded to the monitoring system, and the fault type is indicated through the panel indicator light. If it is a serious fault, the main backup switching process is automatically initiated (in dual redundancy configuration) to ensure continuous operation of the system.

Precautions

5.1 Installation precautions

-The module must be installed in a standard 19 inch cabinet, ensuring that the guide rails are securely fixed during installation to avoid vibration causing the module to loosen or poor interface contact.

-Adequate heat dissipation space should be reserved at the installation location (at least 5cm on both sides of the module), avoiding close stacking with other high-power devices to prevent heat accumulation.

-Before wiring, the module power supply must be disconnected to ensure that the input voltage is consistent with the module specifications (such as DC+5V, ± 12V), and the positive and negative poles must not be reversed to avoid module burnout.

-Connectors such as VME bus interface and Ethernet interface need to be firmly plugged in to ensure good pin contact. After wiring is completed, check whether the interface is loose.

5.2 Precautions for Operation

-During the operation of the module, it is not allowed to randomly plug or unplug interface cables or disassemble the module. If maintenance is required, the power supply must be disconnected and the relevant control programs of the upper computer must be turned off first.

-It is prohibited to modify the core parameters preset by the module (such as bus address and interrupt priority). If adjustments are needed, they must be made by professional technicians according to the system design documents to avoid bus conflicts or system crashes.

-Regularly check the status of the module panel indicator lights. If the fault light is constantly on or flashing, it is necessary to promptly investigate the cause of the fault through the monitoring system to prevent the fault from expanding.

-Avoid firmware upgrades while the module is running. Before upgrading, it is necessary to back up the current configuration parameters. During the upgrade process, ensure network stability to prevent upgrade failures from causing the module to fail to start properly.

5.3 Maintenance and Storage Precautions

-During daily maintenance, it is necessary to regularly clean the dust on the surface of the module and the heat dissipation holes (recommended to do so every 3 months) to avoid dust blockage affecting heat dissipation. Dry soft bristled brushes or compressed air should be used for cleaning, and water or liquid cleaning agents should not be used.

-When the module is not used for a long time, it should be stored in a dry, ventilated, and non corrosive gas environment, avoiding direct sunlight. The storage temperature should be controlled at -40 ℃~+85 ℃, and the relative humidity should be ≤ 95% (no condensation).

-The repair of faulty modules must be carried out by professional technicians authorized by Alstom. It is prohibited to disassemble the module casing or replace core components by oneself, in order to avoid affecting product warranty or causing safety hazards.

Application scenarios

Based on high reliability, strong real-time performance, and flexible scalability, the VME management main module is widely used in fields that require strict control accuracy and system stability, mainly including:

6.1 Rail Transit Signal System

In the signal control systems of subways, light rails, and urban railways, as the core module of the zone controller (ZC) or onboard controller (VC), it is responsible for key tasks such as track section occupancy status acquisition, train speed control, and signal status management. It connects IO modules and communication modules through the VME bus to achieve real-time data exchange with trains and ground equipment, ensuring safe and efficient train operation.

6.2 Industrial Process Control

In the process control systems of industries such as power, chemical, and metallurgy, as the main controller of the on-site control station, it connects temperature, pressure, flow and other sensor acquisition modules, as well as valve, pump and other actuator control modules, to achieve real-time acquisition and closed-loop control of industrial parameters, support integration with factory SCADA systems, and complete centralized monitoring and automation scheduling of the production process.

6.3 Intelligent Equipment Control

In intelligent equipment such as large CNC machine tools and robot production lines, as the control core of the equipment, the motion control module, IO module, and human-machine interaction module are managed to achieve precise control of equipment actions, automated execution of process flow, and real-time monitoring of equipment status, thereby improving the machining accuracy and production efficiency of the equipment.

6.4 Energy Monitoring and Management System

In the energy monitoring system of photovoltaic power plants, wind power plants, and substations, as the main module for data acquisition and control, it is connected to the power quality acquisition module and switch status monitoring module to collect real-time parameters such as power generation, voltage, and current, which are transmitted to the energy management platform through Ethernet. At the same time, it controls the start stop and power adjustment of the power generation equipment according to the platform instructions, achieving efficient utilization of energy.

6.5 Other special industries

In special fields such as aerospace ground testing equipment and ship control systems, with the characteristics of wide temperature range, anti vibration, and high reliability, it serves as the core module for testing or control, undertaking tasks such as equipment status monitoring, test data acquisition and processing, and meeting the needs of use in special environments.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-