ABB WMDOLT2-A75 (65KA) 6E 1TGE106812P0001 is a high-performance input and output (I/O) board developed and produced by ABB Group. It is mainly used in industrial automation control systems, responsible for signal acquisition and instruction execution tasks. It is a key interface component that connects the core unit of the control system with on-site equipment. Among them, "1TGE106812P0001" is the unique material code for this product, used for precise identification and traceability; 65KA "represents its current tolerance parameters under specific operating conditions, providing important basis for engineering selection.

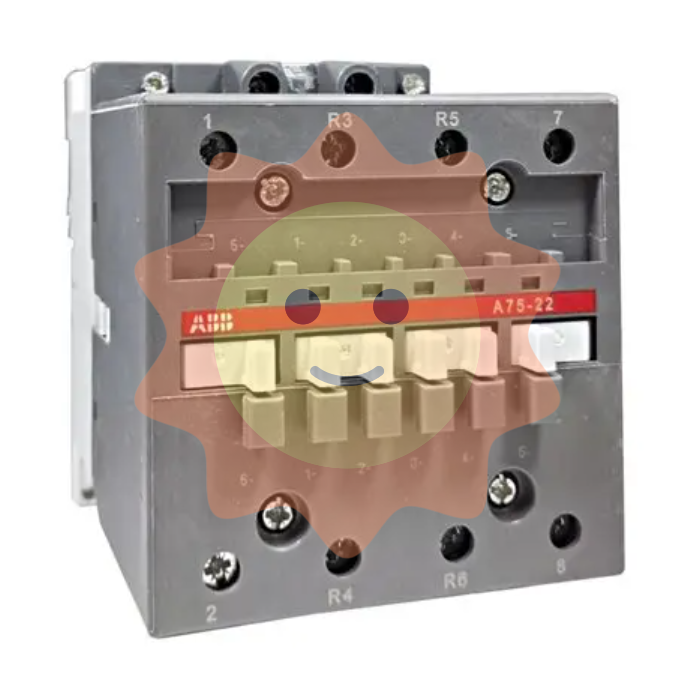

ABB WMDOLT2-A75 (65KA) 6E 1TGE106812P0001 Input and Output Board

Basic Product Information

ABB WMDOLT2-A75 (65KA) 6E 1TGE106812P0001 is a high-performance input and output (I/O) board developed and produced by ABB Group. It is mainly used in industrial automation control systems, responsible for signal acquisition and instruction execution tasks. It is a key interface component that connects the core unit of the control system with on-site equipment. Among them, "1TGE106812P0001" is the unique material code for this product, used for precise identification and traceability; 65KA "represents its current tolerance parameters under specific operating conditions, providing important basis for engineering selection.

Core functions and performance characteristics

1. Multi type signal processing capability

This input and output board has rich interface configurations and is compatible with both analog and digital core signal types. On the input side, it can stably collect signals output by on-site sensors (such as pressure sensors, temperature sensors, proximity switches, etc.), and filter, amplify, and convert the signals through internal signal conditioning circuits to ensure the accuracy and stability of signal transmission; On the output side, corresponding analog control signals or digital switch signals can be output according to the instructions issued by the control system, driving actuators (such as solenoid valves, frequency converters, indicator lights, etc.) to complete corresponding actions and achieve precise control of industrial production processes.

2. High reliability and anti-interference ability

As an industrial grade core component, this product adopts ABB's rigorous production standards and quality control system. Its internal circuit design incorporates multiple anti-interference technologies, including optoelectronic isolation, electromagnetic shielding, etc., which can effectively resist complex electromagnetic interference, voltage fluctuations and other interference factors in industrial sites, ensure the stability of signal transmission, and reduce the risk of misoperation. At the same time, the current withstand design related to "65KA" enables it to maintain normal operation even in the face of instantaneous high current surges, improving the service life and operational reliability of the equipment under harsh working conditions.

3. Convenient integration and maintenance features

The product adopts standardized interface design and modular structure, which can quickly adapt to ABB series control systems and some mainstream industrial automation platforms, simplifying the system integration process. In terms of installation, it supports rail or panel installation, which is convenient for on-site construction and layout adjustment. In addition, the board is equipped with a comprehensive status indicator function, which can intuitively display the power status, signal transmission status, and fault information through LED indicator lights, helping operation and maintenance personnel quickly locate problems and reduce maintenance costs and downtime.

Applicable scenarios

This input and output board, with its stable performance and flexible adaptability, is widely used in industrial fields such as power, metallurgy, chemical engineering, intelligent manufacturing, water treatment, etc. It can be specifically used for production line process control, equipment status monitoring, motor start stop control, instrument data acquisition and other scenarios, providing core support for the efficient and stable operation of industrial automation systems.

Selection and usage precautions

1. Key selection points

-Clearly define the on-site signal type (analog/digital), signal range, and accuracy requirements to ensure compatibility with the board parameters;

-Confirm whether the "65KA" parameter meets the working condition requirements based on the maximum current surge situation on site;

-Verify the control system model and communication protocol to ensure compatibility between the board and the system.

2. Precautions for use

-Before installation, it is necessary to confirm that the power supply voltage is consistent with the rated voltage of the board to avoid overvoltage damage;

-Strictly follow the wiring manual when wiring to ensure that the input and output signals correspond correctly and prevent short circuits;

-Regularly clean and inspect the status of the board to avoid dust, moisture, and other factors affecting equipment performance;

-When repairing or replacing, the power should be cut off first to ensure safe operation.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-