ABB XUD194/XUD194A 3BHC018137R0001 is a high-performance controller unit module designed specifically for industrial complex control scenarios, with a core positioning of "precise computation, stable transmission, and flexible adaptation". Its design logic is based on "industrial grade reliability" and integrates high-frequency processing chips, multi-dimensional signal interfaces, and redundant backup mechanisms. It aims to solve problems such as control instruction delay, signal interference, and poor equipment compatibility in industrial sites, provide real-time and accurate control center support for large industrial equipment, and ensure efficient coordination and stable operation of the entire control system.

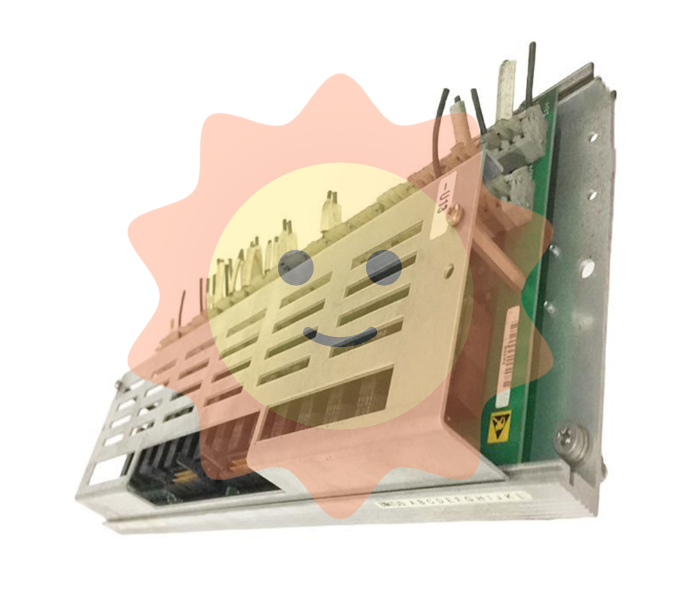

ABB XUD194 XUD194A 3BHC018137R0001 Controller Unit Module

Product core positioning and design logic

ABB XUD194/XUD194A 3BHC018137R0001 is a high-performance controller unit module designed specifically for industrial complex control scenarios, with a core positioning of "precise computation, stable transmission, and flexible adaptation". Its design logic is based on "industrial grade reliability" and integrates high-frequency processing chips, multi-dimensional signal interfaces, and redundant backup mechanisms. It aims to solve problems such as control instruction delay, signal interference, and poor equipment compatibility in industrial sites, provide real-time and accurate control center support for large industrial equipment, and ensure efficient coordination and stable operation of the entire control system.

As an important component of ABB's automation control product family, this module is deeply compatible with ABB high-voltage inverters, motor control units, and other equipment. It can be used as an independent control unit or embedded in complex control systems to undertake core computing functions, with strong application flexibility.

Core technological advantages

1. Efficient computational performance and real-time response

The module is equipped with ABB customized high-frequency 32-bit microprocessor, with a processing frequency of over 200MHz, which can quickly process multi-channel input signals and generate precise control instructions. The instruction response delay is controlled within 1ms, meeting the strict requirements of industrial equipment for real-time control. For complex control algorithms such as PID regulation and logic interlocking control, its built-in dedicated computing core can achieve parallel processing, avoiding the problem of response lag caused by excessive resource consumption of a single task, and ensuring stable computing efficiency in multivariable control scenarios.

2. Strong anti-interference ability and industrial grade stability

Based on the complex electromagnetic environment of industrial sites, this module adopts multiple anti-interference designs: at the hardware level, it is equipped with an independent signal isolation unit to perform optoelectronic isolation processing on analog and digital input and output signals, with an isolation voltage of up to 2500V AC, effectively suppressing common mode interference and differential mode interference; At the software level, signal filtering algorithms are installed to filter high-frequency noise signals input, ensuring the accuracy of signal transmission. At the same time, the module adopts industrial grade wide temperature element devices, with a working temperature range covering -20 ℃~60 ℃, which can adapt to extreme industrial environments such as high and low temperatures. It also has anti vibration and anti moisture structural design, with an MTBF (mean time between failures) of over 100000 hours, greatly reducing the risk of equipment shutdown.

3. Rich interfaces and flexible adaptation capabilities

The module is equipped with diversified interface resources to meet the connection needs of different scenarios: 8-16 digital input interfaces (expandable according to model), supporting dry contact and wet contact signal input; 4-8 analog input interfaces, compatible with standard industrial signals such as 4-20mA and 0-10V, and can be directly connected to sensors, transmitters, and other devices; 6-12 digital output interfaces, supporting relay output and transistor output modes, capable of driving actuators such as contactors and indicator lights; Simultaneously reserve communication interfaces such as RS485 and CANopen, supporting data exchange with the upper computer, touch screen, and other control modules, making it easy to integrate into the distributed control system.

4. Comprehensive fault diagnosis and redundant protection

To enhance the reliability of the control system, the module is equipped with comprehensive fault diagnosis and protection functions: real-time monitoring of key parameters such as its own power supply voltage, chip temperature, and interface signal status. When faults such as abnormal voltage, high temperature, and signal disconnection occur, a fault alarm signal can be immediately triggered, and the fault information can be uploaded to the upper computer through the communication interface, while executing preset safety control logic (such as emergency shutdown, switching to backup modules). Some models support redundant backup function and can form a primary backup redundant system with modules of the same model. When the primary module fails, the backup module can automatically switch to take over control tasks within 50ms, achieving "zero interruption" operation.

5. Convenient debugging and maintenance features

The module supports ABB specific debugging software (such as ABB Control Builder), and engineers can achieve parameter configuration, program download, online monitoring, and other functions through the software without disassembling the module to complete debugging work. At the same time, the module panel is equipped with LED status indicator lights, which can intuitively display power, operation, fault and other status information, making it easy for on-site personnel to quickly judge the operation status of the equipment. In terms of program upgrade, it supports online upgrade function, which can complete firmware updates without interrupting device operation, reducing maintenance costs.

Key technical parameters

model

XUD194 / XUD194A 3BHC018137R0001

Core processor

32-bit customized microprocessor with a clock frequency of ≥ 200MHz

power supply voltage

DC 24V ± 10%, ripple ≤ 100mV

Digital input

8 channels (basic version)/16 channels (enhanced version), with optional dry/wet contacts

Analog input

4-channel (basic version)/8-channel (enhanced version), 4-20mA/0-10V, accuracy ± 0.1%

digital output

6 channels (basic version)/12 channels (enhanced version), relay output (2A/250V AC) or transistor output (0.5A/24V DC)

communication interface

1 RS485 (supporting MODBUS RTU), 1 CANopen (optional)

Calculate response time

≤ 1ms (single instruction processing)

Operating Temperature

-20℃~60℃

Protection level

IP20 (module body), IP40 (with mounting shell)

Isolation voltage

≥ 2500V AC between power supply and I/O, ≥ 1500V AC between I/O

Installation method

DIN rail installation (35mm standard rail)

Typical application scenarios

The controller unit module, with its stable performance and flexible adaptability, plays a core role in control systems in multiple industrial fields. Typical application scenarios include:

1. High voltage frequency converter control system: As the core control unit of ABB high voltage frequency converter, it is responsible for receiving instructions from the upper computer, collecting operating parameters of the frequency converter (such as current, voltage, temperature), realizing start stop control, speed adjustment and fault protection of the frequency converter, and ensuring stable operation of the frequency converter;

2. Auxiliary control system in the power industry: applied to the boiler feedwater control system and induced draft fan regulation system in power plants, collecting signals such as water level, pressure, and flow rate, and accurately controlling the actuator through PID algorithm to ensure efficient operation of auxiliary equipment in power plants;

3. Metallurgical industry steel rolling control system: adapted to the tension control system of the steel rolling mill, real-time collection of roll speed and tension signals, rapid adjustment of control instructions, ensuring stable tension during the steel rolling process, and improving the accuracy of steel rolling;

4. Chemical industry reaction kettle control: used for temperature, pressure, and liquid level control systems of reaction kettles, collecting various parameters inside the reaction kettle, linking and controlling heating devices, feed pumps, and other equipment to ensure that chemical reactions proceed under preset conditions and improve production safety;

5. Pump station control system in the water treatment industry: As the core unit of pump station cluster control, it collects the operating status of each pump and the pressure signal of the pipeline network, realizes the automatic start stop, speed adjustment and fault switching of the pump, and ensures the stability and efficiency of the water supply system.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-