ABB ZM-40-PKZ2 is a stroke block component designed specifically for PKZ2 series motor protection circuit breakers. Its core function is to achieve precise control and status feedback of motor protection through mechanical linkage with contactors. In its model identification, "ZM" represents the product series code, "40" corresponds to the rated current level range of the motor protection circuit breaker it is compatible with, and "PKZ2" specifies its exclusive host series to ensure perfect mechanical and electrical coordination with the PKZ2 series protection device.

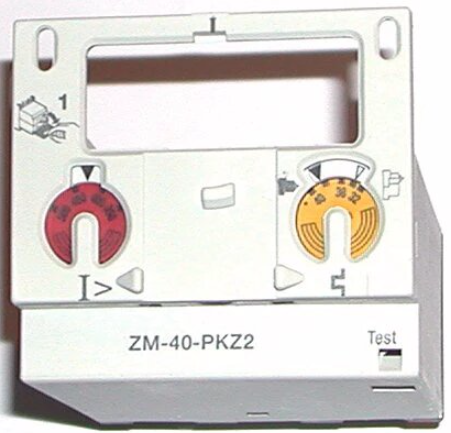

ABB ZM-40-PKZ2 motor protection stroke block

Core positioning and adaptation attributes of the product

ABB ZM-40-PKZ2 is a stroke block component designed specifically for PKZ2 series motor protection circuit breakers. Its core function is to achieve precise control and status feedback of motor protection through mechanical linkage with contactors. In its model identification, "ZM" represents the product series code, "40" corresponds to the rated current level range of the motor protection circuit breaker it is compatible with, and "PKZ2" specifies its exclusive host series to ensure perfect mechanical and electrical coordination with the PKZ2 series protection device.

This travel block adopts a modular structure design and can be directly mounted on the PKZ2 series motor protection circuit breaker without the need for complex additional installation accessories, achieving rapid linkage assembly with the contactor. Its overall size has been accurately calculated, ensuring a tight fit with the host and not occupying too much space inside the distribution box, adapting to the compact distribution layout requirements in industrial scenarios.

Key technical parameters and adaptation specifications

The technical parameters and adaptation performance of ZM-40-PKZ2 stroke block are closely related, and its core parameters and adaptation range are as follows, providing clear basis for selection and system integration:

-Model identification: ZM-40-PKZ2

-Compatible host: ABB PKZ2 series motor protection circuit breaker, especially suitable for PKZ2 products with rated current range matching the "40" specification (specific compatible models need to refer to the product manual, such as PKZ2-40, etc.).

-Mechanical linkage method: snap on mechanical connection, synchronized with the contactor operating mechanism to achieve instant transmission of protection signals.

-Rated insulation voltage: ≥ 690V AC, suitable for medium and high voltage industrial distribution systems, ensuring insulation safety at different voltage levels.

-Working environment temperature: -25 ℃~+60 ℃, suitable for most complex temperature environments such as industrial workshops and outdoor auxiliary equipment, ensuring stable operation under extreme temperatures.

-Protection level: IP20 (when combined with PKZ2 host), effectively preventing solid foreign objects from entering and meeting the basic protection requirements inside the distribution box.

-Mechanical lifespan: ≥ 1 million cycles, matched with the lifespan of the PKZ2 series host, ensuring mechanical reliability during long-term use.

-Installation method: Synchronized with the PKZ2 host, it adopts standard DIN rail installation to achieve overall assembly and disassembly, improving operation and maintenance efficiency.

Core performance advantages

As the "linkage center" of the motor protection system, the ZM-40-PKZ2 stroke block has performance advantages mainly reflected in its collaborative protection effect with the host and its practical characteristics:

1. Precise mechanical linkage, protecting response without delay

Adopting a high rigidity mechanical transmission structure, when the PKZ2 motor protection circuit breaker triggers a tripping action due to overload or phase failure detection, the travel block can instantly synchronize with the contactor to achieve rapid power cut-off of the motor. This mechanical linkage method avoids the delay problem of electrical signal transmission, and the entire process from fault detection to power cut-off is extremely time-consuming, minimizing damage to the motor winding caused by faults and reducing maintenance costs.

2. Exclusive adaptive design, with excellent compatibility and stability

As an exclusive component of the PKZ2 series, ZM-40-PKZ2 seamlessly integrates with the host in terms of structural dimensions and connection interfaces. Its snap on installation design not only ensures firm assembly and avoids looseness or displacement caused by vibration during operation, but also ensures consistency in each linkage action, without protection failure or misoperation due to adaptation issues, significantly improving the operational stability of the entire motor protection system.

3. Modular structure, easy installation and maintenance

The travel block adopts an independent modular design, and there is no need to modify the structure of the PKZ2 host during installation. It can be assembled directly by clamping, greatly reducing installation time. In the later stage of operation and maintenance, if the travel block malfunctions, it can be disassembled and replaced separately without the need to replace the motor protection device as a whole, reducing operation and maintenance costs and downtime. At the same time, its surface design is simple, without complex circuit connections, making it easy for operation and maintenance personnel to quickly inspect and maintain.

4. High strength material, suitable for harsh industrial environments

The shell and internal transmission components are made of high-strength engineering plastics and wear-resistant metal materials, which have excellent impact resistance, aging resistance, and corrosion resistance. It can resist common dust, oil stains, slight vibrations, and temperature fluctuations in industrial scenarios, and will not cause mechanical jamming or structural damage due to environmental factors, ensuring stable linkage performance under harsh working conditions.

5. Well designed safety measures that comply with international standards

The product has been certified by international electrical standards such as IEC 60947 and Chinese GB standards, and its insulation performance, mechanical strength, and protection linkage accuracy have all reached the international advanced level. Internally designed with anti misoperation structure, it can effectively prevent personnel from contacting live parts during installation and maintenance, improving operational safety; At the same time, the collaborative protection mechanism with PKZ2 host can comprehensively cover common motor faults, forming a dual safety guarantee.

Applicable scenario

Based on its compatibility with the PKZ2 series host and reliable linkage protection performance, the ZM-40-PKZ2 stroke block is widely used in various industrial and civilian scenarios that rely on small and medium-sized motors, including:

-General industrial equipment: motor protection circuits for general machinery such as machine tools, fans, water pumps, conveyors, etc., such as conveyor motors for workshop production lines and water pump motors for cooling systems, ensure continuous and stable operation of the equipment through precise linkage protection, and avoid production line shutdowns caused by motor failures.

-HVAC system: Protection of air conditioning units and ventilation fan motors in large buildings such as shopping malls, office buildings, and factory workshops. Under frequent start stop conditions of the air conditioning system, stable linkage protection is used to extend the service life of the motors and ensure the normal operation of the HVAC system.

-Water supply, drainage, and sewage treatment: The protection circuits of the pressurized water pump in the water plant, the aeration fan in the sewage treatment plant, and the mixing motor ensure the reliable operation of the motor protection system under humid and dusty conditions, and avoid the impact of motor failure on water supply, drainage, and sewage treatment efficiency.

-Agriculture and food processing: The protection of water pump motors for agricultural irrigation, conveyor belt motors and mixing motors for food processing plants, adapts to the outdoor environment of agricultural scenes and the cleaning requirements of food processing scenes, ensures the safe operation of motors, and guarantees the continuity of agricultural production and food processing.

-Construction and engineering machinery: The motor protection circuit of small cranes, elevators, mixers and other construction machinery achieves reliable linkage protection through high-strength materials and stable installation design under strong vibration conditions, improving the safety and efficiency of construction.

Installation and usage precautions

Proper installation and use are key to ensuring optimal performance of the ZM-40-PKZ2 travel block, with particular attention to the following points:

1. Installation specifications

Before installation, it is necessary to confirm that the travel block model matches the PKZ2 motor protection circuit breaker model to avoid mismatching and linkage failure; When installing, first fix the PKZ2 host on the DIN rail, then align the travel block with the buckle interface of the host, gently press until you hear a "click" sound, and confirm that the card is firmly installed; During the installation process, avoid forcefully tapping the travel block to prevent damage to the internal transmission structure; Ensure that the position of the travel block and the linkage rod of the contactor are aligned without deviation to avoid affecting the linkage accuracy.

2. Key points for use and maintenance

During the equipment debugging phase, it is necessary to manually test the tripping action of the PKZ2 host, check whether the linkage between the travel block and the contactor is smooth, and ensure that the contactor can be synchronously disconnected when the host trips; In daily operation and maintenance, it is necessary to regularly check the clamping status of the travel block to avoid loosening due to vibration, and clean the dust and oil on its surface to prevent mechanical jamming; If it is found that the linkage of the travel block is not smooth or cannot move synchronously, it should be disassembled and inspected in a timely manner to check whether the internal transmission components are worn or stuck, and replaced if necessary; When replacing the travel block, it is necessary to first cut off the power supply of the relevant circuit to ensure safe operation.

3. Special precautions

It is prohibited to use the ZM-40-PKZ2 travel block for non PKZ2 series motor protection devices to avoid protection failure due to improper adaptation; Avoid using under operating conditions that exceed its rated ambient temperature, humidity, and vibration range to prevent performance degradation; If the travel block experiences unexpected situations such as strong impact or immersion, it must be stopped from use and professionally tested to confirm that there are no faults before it can be put back into operation.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-