The 1MRK002247 Apr04 transformer module is an important component of ABB Relion series protection and control product system, specially designed for medium and high voltage transformers. This module is based on a microprocessor and integrates advanced monitoring algorithms and reliable control logic. It can collect real-time operating data of transformers, accurately judge the equipment's operating status, and quickly trigger protection actions in case of abnormalities. At the same time, it has the ability to upload data and communicate remotely, adapting to the intelligent operation and maintenance needs of modern power systems. The Apr04 version has been optimized and upgraded in terms of hardware stability and software algorithms, further enhancing its adaptability in complex power grid environments.

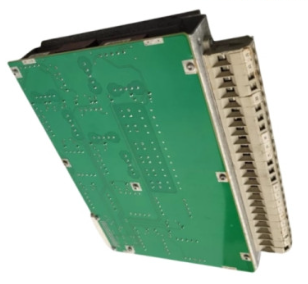

ABB 1MRK002247 Apr04 Transformer Module

Product Overview

The 1MRK002247 Apr04 transformer module is an important component of ABB Relion series protection and control product system, specially designed for medium and high voltage transformers. This module is based on a microprocessor and integrates advanced monitoring algorithms and reliable control logic. It can collect real-time operating data of transformers, accurately judge the equipment's operating status, and quickly trigger protection actions in case of abnormalities. At the same time, it has the ability to upload data and communicate remotely, adapting to the intelligent operation and maintenance needs of modern power systems. The Apr04 version has been optimized and upgraded in terms of hardware stability and software algorithms, further enhancing its adaptability in complex power grid environments.

Core functional features

1. Comprehensive status monitoring

The module has multi-dimensional data acquisition capabilities and can monitor the core operating parameters of transformers in real time, including three-phase current, voltage, power factor, winding temperature, oil temperature, and oil level. By using built-in high-precision sensor interfaces and data processing units, the accuracy of collected data is ensured, and errors are controlled at industry-leading levels. At the same time, the module supports real-time analysis of data, automatically identifying potential fault hazards such as overcurrent, overvoltage, overtemperature, and abnormal oil level, and forming warning information.

2. Reliable protection mechanism

Based on ABB's mature protection algorithm, this module integrates multiple targeted protection functions, including quick break protection, overcurrent protection, differential protection, gas protection, temperature protection, etc. When a fault is detected, the module can respond within milliseconds by triggering corresponding protective actions through trip outputs or signal feedback, effectively isolating the fault area and avoiding the expansion of the fault from causing greater losses to the transformer and the entire power system. The protection parameters support flexible configuration and can be personalized according to the needs of different application scenarios.

3. Intelligent control and communication

The module supports intelligent control of auxiliary equipment of transformers, such as automatic start stop control of cooling fans and oil pumps, and automatically adjusts the operating status of auxiliary equipment according to the load rate and temperature of transformers, achieving energy conservation and consumption reduction. In terms of communication, the module is compatible with multiple industrial communication protocols, such as IEC 61850, Modbus, etc., and can seamlessly integrate into the power monitoring system (SCADA) to achieve remote uploading of operational data, remote monitoring of equipment status, and remote configuration of protection parameters, thereby improving operation and maintenance efficiency.

4. Fault recording and diagnosis

The module is equipped with a large capacity storage unit, which can automatically record the operation logs, fault events, and waveform data of the transformer, including key information such as fault occurrence time, fault type, and parameter changes during the fault, providing strong basis for fault tracing and analysis. At the same time, it has a self diagnostic function that can monitor the hardware status and communication links of the module in real time. When a module failure occurs, it can issue an alarm in a timely manner, which is convenient for operation and maintenance personnel to quickly locate and handle the problem.

Key technical parameters

power input

DC 24V/48V/110V/220V

Wide voltage range adaptation to meet the needs of different power scenarios

Current measurement range

0-1000A (connected through current transformer)

Support different ratio current transformers, which need to be selected in coordination

Voltage measurement range

0-100V (line voltage or phase voltage)

Based on voltage transformer connection, measurement accuracy of 0.2 level

Temperature measurement range

-40℃-150℃

Support the integration of commonly used temperature sensors such as Pt100

Protection action time

≤ 50ms (quick break protection)

The action time of different protection functions can be configured

communication interface

Ethernet、RS485

Supports IEC 61850, Modbus RTU/TCP protocols

working environment

Temperature: -25 ℃ -70 ℃; Humidity: 5% -95% (no condensation)

Adapt to harsh industrial environments

Overall dimensions

145mm x 100mm x 210mm (length x width x height)

Modular design for easy installation inside the cabinet

Applicable scenarios

This module, with its stable performance and flexible configuration, is widely used in the following scenarios:

-Power system substation: Suitable for medium and high voltage transformers such as 110kV and 220kV, serving as the core protection and monitoring unit to ensure the safe operation of the substation;

-Industrial enterprise power distribution system: used for self provided transformers in large industrial enterprises such as steel, chemical, and manufacturing industries, meeting the high requirements for power reliability in industrial production;

-New energy supporting facilities: applied in the step-up transformers of wind and photovoltaic power plants to achieve precise monitoring and protection of new energy grid connected transformers;

-Urban distribution network: Adapt to the distribution transformers in the urban distribution network, improve the intelligent level of operation and maintenance of the distribution network, and reduce power outage time.

Product advantages

1. High reliability: Using ABB industrial grade components and strict production testing processes, the mean time between failures (MTBF) exceeds 100000 hours, adapting to complex and harsh operating environments;

2. High degree of intelligence: integrating advanced data analysis algorithms and remote communication functions, supporting seamless integration with smart power platforms, and helping to achieve the digital transformation of the power system;

3. Flexible adaptability: wide voltage input, multi protocol compatibility, and configurable protection parameters enable it to adapt to transformers of different specifications and diverse application scenarios;

4. Convenient operation and maintenance: Supports local panel operation and remote operation and maintenance, with clear and complete fault records, greatly reducing the workload and troubleshooting difficulty of operation and maintenance personnel;

5. Brand guarantee: Relying on ABB's profound technical accumulation and global service network in the power field, we can provide users with professional technical support and fast after-sales service.

Precautions

-Module installation must be carried out by professional technicians in accordance with ABB's official installation manual to ensure correct and secure wiring, and to avoid equipment failure caused by improper installation;

-Before putting into operation, precise configuration of protection parameters is required, and reasonable protection thresholds should be set based on the rated parameters of the transformer, operating environment, and system requirements;

-Regularly maintain and inspect modules, including cleaning equipment surfaces, checking communication links and sensor connection status, to ensure stable operation of the equipment;

-Module firmware upgrade requires the use of ABB's official upgrade program and authorization files to avoid equipment damage or functional abnormalities caused by unofficial upgrades.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-