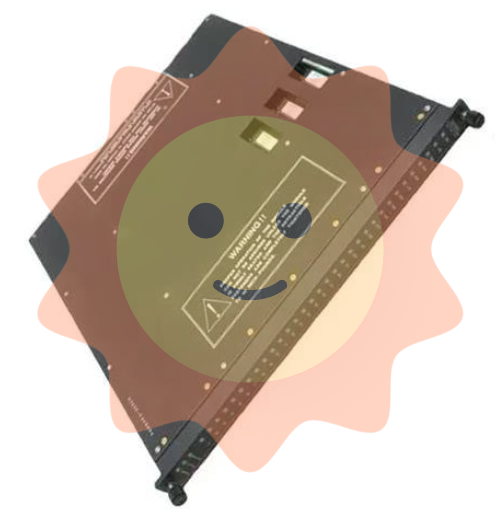

TRICON 20064-320 I/O Module

Product Introduction: The TRICON 20064-320 is a versatile, high-density digital input/output (I/O) module integral to the Triconex safety platform. Engineered for demanding industrial environments, it facilitates the reliable interface between the Triple Modular Redundant (TMR) safety controller and field devices such as switches, solenoids, and indicators, forming a crucial part of Safety Instrumented Functions (SIFs).

Module Overview and System Integration

The TRICON 20064-320 module is a fundamental component within a Triconex Safety Instrumented System (SIS), a platform renowned for its robust protection of critical industrial processes. This specific module serves as a high-density digital interface, providing a configurable array of points that can be defined as inputs to monitor process states or as outputs to execute control actions. Its primary role is to ensure the accurate and timely flow of binary (on/off) information between the field and the fault-tolerant TMR main processor. This reliable data exchange is paramount for the SIS to correctly assess hazardous conditions and initiate predefined safety responses, such as an emergency shutdown.

Key Features and Technical Design

High-Density & Flexible Configuration

The "high-density" design of the 20064-320 allows for a significant number of I/O channels on a single module, optimizing chassis space and reducing system footprint. Each channel is independently configurable as a digital input (DI) or digital output (DO) through software, offering exceptional flexibility to system integrators. This adaptability simplifies design, inventory management, and allows for last-minute changes without requiring hardware modifications.

Advanced Diagnostic Coverage

Reliability in safety systems is non-negotiable. The module incorporates comprehensive continuous diagnostics. For input channels, it verifies signal integrity, while output channels are monitored for faults such as short circuits, open loads, and overload conditions. These diagnostics are processed within the TMR architecture, enabling the system to identify, report, and often tolerate a fault without compromising the overall safety function, thereby maximizing system availability.

Robust TMR Integration

The module is designed for seamless operation within the Triple Modular Redundant framework. It connects directly to the triple redundant Triconex backplane. Critical data and diagnostics are communicated simultaneously to all three main processors. This deep integration ensures that the I/O module's status is consistently known across the entire TMR system, maintaining the integrity of the voting process and the system's fault-tolerant capabilities.

Detailed Technical Specifications

The following table outlines the primary technical attributes of the TRICON 20064-320 module, highlighting its capabilities and design parameters for industrial deployment.

Hot Swap Capability Typically supported, allowing removal and insertion without system power-down

Primary Industrial Applications

The TRICON 20064-320 module is deployed across a wide spectrum of industries where functional safety is critical. Its reliability and flexibility make it suitable for various safety interlocks and shutdown functions.

Emergency Shutdown Systems (ESD): Monitoring initiation devices (e.g., push buttons, pressure switches) and activating shutdown valves and actuators.

Fire & Gas Detection and Control: Receiving signals from gas detectors and flame sensors, and activating alarms, ventilation fans, or fire suppression systems.

Burner Management Systems (BMS): Managing permissives and sequences for safe furnace start-up, operation, and shutdown.

Turbo-machinery Control: Overspeed protection by monitoring speed sensors and triggering trip solenoids.

Process Interlocks: Enforcing safe operating sequences in chemical reactors, compressors, and other critical equipment.

Discrete Safety Signaling: Providing status indications and receiving acknowledgments from operator workstations.

Value Proposition and System Benefits

Integrating the TRICON 20064-320 module into a safety system offers significant advantages. Its high-density design reduces the number of modules required for a given application, lowering overall system cost and complexity. The software-configurable channels provide unparalleled design flexibility, shortening engineering time and accommodating process changes efficiently. Most importantly, its built-in diagnostics and robust TMR integration contribute directly to a lower Probability of Failure on Demand (PFD), enhancing the safety integrity of the entire loop. These features, combined with the Triconex platform's proven track record, deliver a solution that balances high performance, reliability, and lifecycle cost-effectiveness for mission-critical safety applications.

Conclusion

The TRICON 20064-320 configurable digital I/O module represents a critical link in the chain of safety for modern industrial facilities. By offering high density, flexible configuration, and robust diagnostics within the trusted Triconex TMR architecture, it provides system designers with a reliable and efficient tool for interfacing with the physical world. Its role in accurately gathering data from the field and executing safety commands is indispensable for protecting personnel, environment, and assets in high-hazard industries worldwide.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-