This controller module is an important member of ABB's industrial control module system, with 3BHE017628R0002 as the core order number, used for precise positioning of product specifications and production batches; PPD115A02 is the specific model of the module, specifying its functional positioning and technical parameters; SG579989013 is a product identification code that facilitates traceability management throughout the entire lifecycle. The product adopts industrial grade modular design, complies with IEC industrial standards, has a compact hardware structure, and is compatible with various ABB standard control cabinets. It can work stably in a wide temperature environment of -20 ℃~60 ℃ and a humidity condition of 5%~95% without condensation, easily coping with harsh environments in industrial sites.

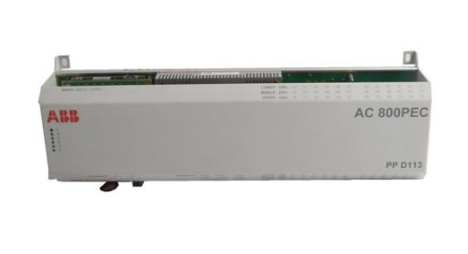

ABB 3BHE017628R0002 PPD115A02 SG579989013 Controller Module

Core Basic Information

This controller module is an important member of ABB's industrial control module system, with 3BHE017628R0002 as the core order number, used for precise positioning of product specifications and production batches; PPD115A02 is the specific model of the module, specifying its functional positioning and technical parameters; SG579989013 is a product identification code that facilitates traceability management throughout the entire lifecycle. The product adopts industrial grade modular design, complies with IEC industrial standards, has a compact hardware structure, and is compatible with various ABB standard control cabinets. It can work stably in a wide temperature environment of -20 ℃~60 ℃ and a humidity condition of 5%~95% without condensation, easily coping with harsh environments in industrial sites.

Core functions and performance advantages

1. High precision computation and multi-dimensional control capability

The module is equipped with a 32-bit high-performance industrial processor, with high computing frequency and strong data processing capability. It supports multiple control algorithms such as multi loop PID control, logic interlocking control, sequential control, and fuzzy control. It can collect various on-site signals in real-time, such as analog signals (such as temperature, pressure, flow rate) and digital signals (such as equipment start stop status), and output control instructions through precise calculation. The control accuracy error can be controlled within ± 0.1%, effectively ensuring the stability of industrial process parameters, reducing production fluctuations, and improving product qualification rate.

2. High integration and flexible scalability features

Adopting highly integrated circuit design, multiple functional interfaces such as analog input/output (AI/AO), digital input/output (DI/DO), pulse input/output (PI/PO), etc. are integrated within a compact module size, which can meet conventional control requirements without the need for additional expansion modules. Simultaneously supporting modular expansion, communication modules, signal conditioning modules, etc. can be flexibly connected through ABB standard bus interfaces, expanding the number and functional range of control channels, adapting to different application requirements from small and medium-sized equipment to large control systems, and reducing system integration costs.

3. Excellent anti-interference and reliability performance

In response to the complex electromagnetic environment of industrial sites, the module adopts multiple anti-interference designs, including optoelectronic isolation, electromagnetic shielding, surge protection and other technologies, which can effectively resist strong electromagnetic radiation, voltage fluctuations and electrostatic interference, and comply with the EN 61000-6-2 industrial anti-interference standard. The key components adopt military grade quality control, and undergo multiple rounds of reliability testing such as high and low temperature cycling, vibration impact, aging, etc. The average time between failures (MTBF) exceeds 100000 hours, greatly reducing the risk of equipment failure and ensuring the continuity of industrial production.

4. Efficient communication and system compatibility capability

Built in CANopen, PROFIBUS-DP, EtherCAT and other mainstream industrial communication interfaces, supporting seamless communication with ABB G2000 series human-machine interface, PLC, SCADA system and third-party intelligent devices. The data transmission rate can reach up to 100Mbps, ensuring real-time interaction between control commands and status data. Simultaneously compatible with ABB industrial control software (such as AC 800M Control Builder), supporting online programming, debugging, and program downloading, simplifying development and maintenance processes.

5. Comprehensive self diagnosis and security protection functions

Equipped with comprehensive self diagnostic function, it can monitor the power status, CPU operation, interface communication, and external device connection of the module in real time. When a fault occurs, it can immediately output a signal through the alarm interface and display the fault code and location on the human-machine interface, making it easy for operation and maintenance personnel to quickly locate and troubleshoot the problem. At the same time, it is equipped with overcurrent, overvoltage, and short-circuit protection circuits, which automatically cut off the circuit when the input and output signals are abnormal, avoiding damage to modules and external devices and improving the safety of system operation.

Typical application scenarios

With its excellent performance and wide compatibility, this controller module has been deeply applied in multiple key industrial fields, including:

-Power industry: used for speed control of steam turbine generator units in thermal power plants, boiler feedwater control systems, and logic control of auxiliary equipment in nuclear power plants to ensure stable operation and efficient energy output of power generation equipment.

-Metallurgical industry: applied to oxygen supply control for converter steelmaking in steel plants, speed control for continuous casting machines, and tension control for steel rolling production lines, achieving precise control of metallurgical processes and improving steel quality.

-Chemical industry: Suitable for multi parameter linkage control of temperature, pressure, and liquid level in chemical reaction vessels, as well as material conveying pump group control in chemical parks, to meet the requirements of high precision and high safety in chemical production.

-In the field of industrial robots, as the core control module of robot control cabinets, it achieves precise control of robot joint movements, path planning, and action interlocking, improving the accuracy and stability of robot operations.

-In the field of new energy storage, it is used for charge and discharge control of energy storage systems, battery status monitoring, and energy scheduling to ensure the coordinated operation of energy storage systems and the power grid, and to improve energy utilization efficiency.

Installation and maintenance precautions

1. Installation requirements

Adopting guide rail or screw fixed installation, the installation position should be far away from high-temperature heat sources, corrosive gases, and strong vibration sources to ensure good heat dissipation of the module; Before wiring, it is necessary to confirm that the power supply voltage is consistent with the rated voltage of the module, and strictly follow the definition of the wiring terminal for wiring. Analog and digital circuits should be laid separately to avoid signal interference; After installation, it is necessary to check whether the module is firmly fixed and whether the wiring is tight to prevent loosening and poor contact.

2. Maintenance points

Regularly clean the dust on the surface of the module and the heat dissipation holes to maintain smooth heat dissipation; Regularly backup control programs and parameter configurations through control software to prevent data loss; Regularly check the fastening status of the wiring terminals and the operating temperature of the module, and promptly handle any abnormalities found; Avoid plugging and unplugging modules with power on. When replacing modules, cut off the power first to ensure safe operation.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-