REM615 is a classic model of ABB motor protection control series, with HBMBCCAHNB1XD as the specific configuration identifier, covering key information such as hardware version, functional modules, and communication configuration, ensuring precise matching between product selection and application scenarios. The equipment follows international standards such as IEC 61850 and IEC 60255, adopts industrial grade high protection design, and has a body protection level of IP30 (for cabinet installation). It can work stably in a wide temperature environment of -40 ℃~70 ℃ and at an altitude of below 4000m, and is suitable for installation and operation requirements in various harsh industrial sites.

ABB REM615 HBMBCCAHNB1NN1XD Motor Protection Control

Core Basic Information

REM615 is a classic model of ABB motor protection control series, with HBMBCCAHNB1XD as the specific configuration identifier, covering key information such as hardware version, functional modules, and communication configuration, ensuring precise matching between product selection and application scenarios. The equipment follows international standards such as IEC 61850 and IEC 60255, adopts industrial grade high protection design, and has a body protection level of IP30 (for cabinet installation). It can work stably in a wide temperature environment of -40 ℃~70 ℃ and at an altitude of below 4000m, and is suitable for installation and operation requirements in various harsh industrial sites.

Core functions and performance advantages

1. Comprehensive and precise protection function

The device is equipped with multi-dimensional protection algorithms, which can achieve comprehensive fault protection for motors. Including overcurrent protection (including definite time and inverse time characteristics), which can intelligently adjust the protection action time according to the degree of current abnormality; Overload protection accurately simulates the heating process of motor windings through thermal accumulation calculation, avoiding damage to the motor due to long-term overload; It also has functions such as short circuit protection, phase loss protection, ground fault protection, locked rotor protection, undervoltage/overvoltage protection, etc. The protection parameters can be flexibly configured, with a response time of up to 1ms. It can quickly cut off the motor power supply in the event of a fault, minimizing the risk of equipment damage.

2. Real time monitoring and data collection capability

Equipped with powerful parameter acquisition and monitoring functions, it can real-time collect key operating parameters such as three-phase current, voltage, power, power factor, winding temperature, bearing temperature, etc. of the motor, with a sampling accuracy of 0.2 level, ensuring the accuracy of the data. Through the built-in human-machine interaction interface (or external HMI), real-time parameters, equipment operating status, and fault information can be intuitively displayed. It also supports parameter trend recording and can store historical operating data and fault events (with a recording capacity of over 1000), providing reliable data support for motor operation analysis, fault tracing, and preventive maintenance.

3. Flexible control and operational functions

Supports multiple control modes, including local manual control, remote automatic control, and PLC linkage control, to meet the operational needs in different scenarios. It can achieve various control logics such as direct start stop, forward and reverse control, star delta start control, etc. of the motor. The control methods can be flexibly configured through software configuration without the need for additional hardware wiring modifications. At the same time, it has the function of monitoring the control circuit, which can monitor the on/off status of the control circuit in real time, avoiding the motor from being unable to start and stop normally due to control circuit faults.

4. High reliability and anti-interference design

Adopting a dual CPU architecture design, each responsible for protecting computation and data processing, ensuring the independence and real-time performance of protection functions, and avoiding protection failure caused by a single CPU failure. In terms of hardware, military grade components are used, and multiple isolation and surge protection circuits are set up for key circuits. The anti electromagnetic interference capability meets the IEC 61000-4 series standards, which can effectively resist strong electromagnetic radiation, voltage fluctuations, and electrostatic interference in industrial sites. The average time between failures (MTBF) of the equipment exceeds 200000 hours, ensuring long-term stable operation.

5. Strong communication and system integration capabilities

Built in rich communication interfaces, supporting mainstream industrial communication protocols such as IEC 61850, Modbus RTU/TCP, PROFIBUS-DP, etc., can seamlessly integrate into substation automation systems (SAS), SCADA systems, or factory energy management systems, realizing remote uploading of motor operation data and remote issuance of control instructions. Support IEC 61850 GOOSE message interaction, enabling fast information exchange with other intelligent devices, enhancing the system's collaborative control capabilities, and adapting to the construction needs of smart factories and digital substations.

Typical application scenarios

With its comprehensive protection functions and flexible adaptability, ABB REM615 HBMBCCAHNBA1ANN1XD is widely used in various medium and high voltage motor control scenarios, mainly including:

-Power industry: used for the protection and control of auxiliary motors such as induced draft fans, supply fans, and feed pumps in thermal power plants, as well as the operation guarantee of cooling fans and oil pump motors in substations, to ensure the stable operation of power production auxiliary control systems.

-Petrochemical industry: applied to the protection and control of reaction kettle stirring motors and oil pipeline pump group motors in refineries. Through precise protection and rapid fault response in flammable and explosive industrial environments, it ensures production safety and process continuity.

-Metallurgical industry: Suitable for the protection and control of large motors such as blast furnace blowers and converter dust removal fans in steel plants, capable of withstanding high temperature and high dust environments in metallurgical workshops, ensuring stable operation of motors under high load conditions.

-In the field of municipal engineering, it is used for the protection and control of aeration tank fans, sewage lift pump motors, and water supply pump motors in sewage treatment plants, ensuring the stable operation of municipal public facilities and improving the reliability of livelihood services.

-Mining and cement industry: applied to the protection and control of mining crusher motors and cement production line rotary kiln drive motors, providing targeted protection solutions for heavy-duty and frequent start stop working conditions to extend the service life of motors.

Installation and maintenance precautions

1. Installation requirements

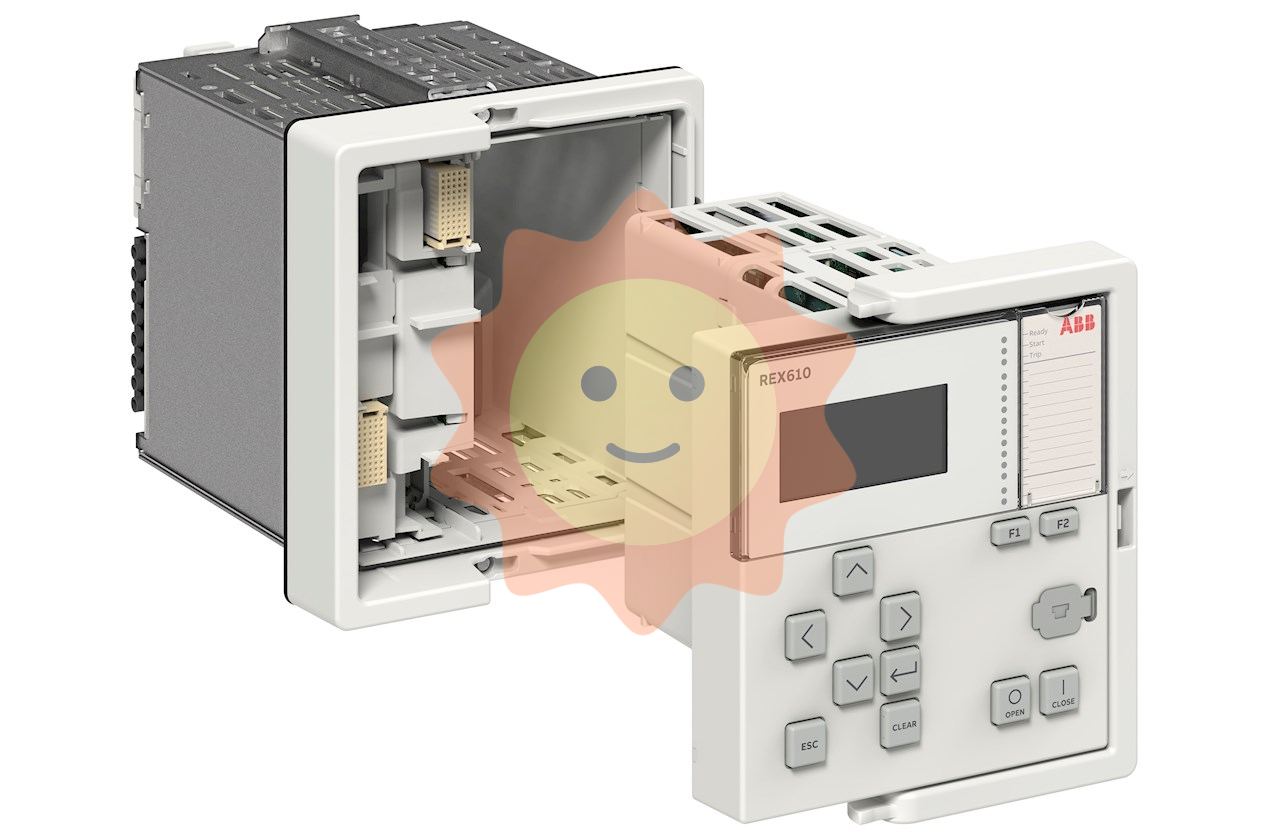

Adopting embedded installation in the cabinet, holes should be reserved according to the installation size of the equipment to ensure a firm installation and easy operation and maintenance; The installation location should be away from high temperature heat sources, strong magnetic fields, and corrosive gases, avoiding direct sunlight and ensuring good ventilation and heat dissipation of the equipment; When wiring, it is necessary to strictly distinguish between power circuits, current circuits, voltage circuits, and control circuits. Open circuits are strictly prohibited for current circuits, and short circuits are strictly prohibited for voltage circuits. All wiring terminals must be securely fastened to prevent measurement errors or protection misoperations caused by poor contact.

2. Maintenance points

Regularly clean the dust on the surface of the equipment and ventilation holes to maintain smooth heat dissipation; Regularly check whether the protection parameter settings match the rated parameters of the motor through the device panel or backend software to ensure that the protection function is effective; Regularly verify the accuracy of current and voltage sampling, which can be calibrated using a standard signal source; Regularly backup device configuration parameters and historical data to prevent parameter loss; When the equipment malfunctions, the power should be disconnected first, and the problem should be investigated by combining the fault code with historical records to avoid live operation.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-