ABB 3HAC4776-1/1 is a specialized control module for the field of robotics and high-end automation, belonging to the ABB IRC5 robot controller series of I/O expansion modules. Its core function is to achieve signal interaction and collaborative control between robot systems and external devices (such as sensors, actuators, and production line conveying equipment). It is widely used in robot automation scenarios that require high synchronization, such as automotive manufacturing, 3C electronic assembly, and precision machining.

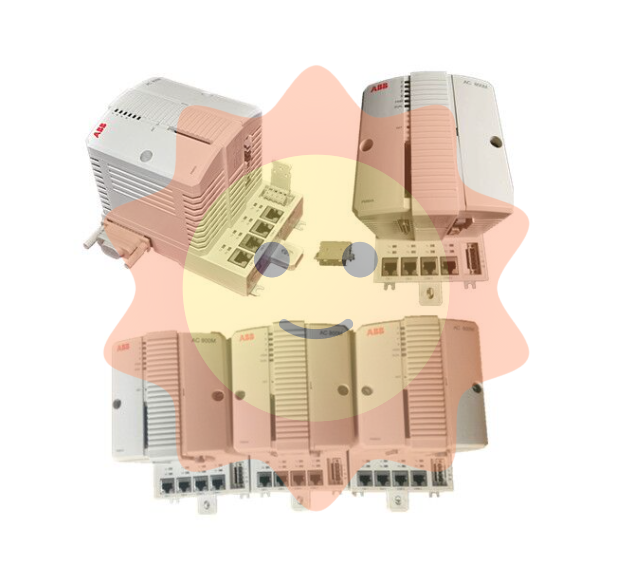

ABB 3HAC4776-1/1 Industrial Control Module

Product positioning and core values

ABB 3HAC4776-1/1 is a specialized control module for the field of robotics and high-end automation, belonging to the ABB IRC5 robot controller series of I/O expansion modules. Its core function is to achieve signal interaction and collaborative control between robot systems and external devices (such as sensors, actuators, and production line conveying equipment). It is widely used in robot automation scenarios that require high synchronization, such as automotive manufacturing, 3C electronic assembly, and precision machining.

Its core value lies in "high synchronization control+strong compatibility+high reliability": supporting millisecond level signal synchronization with robot controllers to ensure precise linkage between robot actions and external devices; Compatible with ABB's full range of industrial robots (such as IRB 6700, IRB 1200) and third-party automation equipment; Adopting industrial grade redundancy design to adapt to high load and continuous production industrial environments, reducing production line downtime caused by module failures.

Core parameters and functional characteristics

1. Key electrical and performance parameters

Signal processing capability

Digital input (DI): 16 channels, 24V DC (leakage type input, response time ≤ 1ms); Digital output (DO): 16 channels, 24V DC (source type output, maximum load of 2A per channel, short-circuit protection current of 5A); No analog channel, specialized analog module needs to be expanded (such as 3HAC4776-2/1)

Synchronization performance

Supports real-time I/O bus connection with ABB IRC5 robot controller, with signal synchronization error ≤ 0.5ms, meeting high-precision linkage requirements such as robot assembly and welding

Communication interface

1 robot specific bus interface (compatible with IRC5 controller's I/O expansion port), 1 RS485 serial port (supporting Modbus RTU protocol for third-party device communication)

Power parameters

24V DC power supply (input range 20-28V DC), power consumption ≤ 10W, with overvoltage (protection threshold 32V DC), overcurrent (protection threshold 3A), and reverse connection protection functions

Environmental adaptability

Working temperature range from 0 ℃ to 55 ℃ (narrower than conventional module temperature range, requiring cabinet heat dissipation), relative humidity of 5% -95% (no condensation), protection level IP20 (module body), anti vibration performance of 5-500Hz, 0.2g

Security certification

Complies with CE (EN 61508 SIL 2) and UL (UL 1998) safety standards, meets the safety control requirements of industrial robots, and supports emergency stop signal access

2. Core functional features

Robot synchronization control: By linking with the IRC5 controller through a dedicated real-time bus, external sensor signals (such as workpiece positioning signals) can be directly integrated into the robot control program, achieving closed-loop control of "sensor detection → robot action adjustment". For example, in the automotive welding production line, when the DI channel detects a workpiece position deviation, the module transmits the signal to the robot controller within 1ms, and the robot adjusts the welding gun position in real time, with a welding accuracy error of ≤ 0.1mm

Output load protection: All 16 DO channels have independent short-circuit protection and overload protection. When a short circuit occurs at the output end (such as wire misconnection), the module automatically cuts off the power supply of that channel, and other channels work normally to avoid fault propagation; After troubleshooting, the module automatically restores channel power supply (without manual reset), reducing manual intervention.

Diagnosis and monitoring: Support real-time viewing of module working status (DI/DO signal on/off, power supply voltage, bus connection status) through robot teaching aids (such as FlexPendant); All fault information (such as DO short circuit, bus interruption) is automatically stored in the controller log and can be exported and analyzed through ABB RobotStudio software, reducing the troubleshooting time to within 30 minutes.

Scalability: The module is equipped with an "expansion interface" on the side, which can cascade up to 3 modules of the same model (3HAC4776-1/1) or dedicated analog modules (3HAC4776-2/1). After expansion, it can support up to 64 DI+64 DO channels, adapting to the multi device control requirements of large robot workstations (such as multi station assembly lines).

Adaptation devices and collaborative applications

1. Core adaptation equipment

Robot controller

ABB IRC5 robot controller (such as 3HAC028357-001) achieves signal synchronization through a dedicated bus cable (3HAC031683-001)

Terminal unit

ABB DSTF610 terminal unit (solves the problem of insufficient module terminals by transferring external sensor signals through TK520 cable), ABB TU515 terminal unit (suitable for simple scenarios with few signal points)

External devices

24V DC photoelectric sensor (such as ABB O5F series, used for workpiece detection), travel switch (such as ABB LS45 series, used for robot limit protection), solenoid valve (controlling fixture opening and closing), indicator light (production line status display)

Connecting cables

Robot specific bus cable (3HAC031683-001, length 1m/3m optional), TK520 shielded cable (module connected to DSTF610 terminal unit), 2.5mm ² copper wire (terminal unit connected to external equipment)

2. Collaborative application case with DSTF610 terminal unit: Automotive parts robot assembly line

System architecture: The assembly line needs to implement an automated process of "robot grabbing workpieces → conveyor belt conveying → robot assembly → unloading after passing inspection", involving 12 workpiece detection signals (DI), 8 fixture control signals (DO), and 6 conveyor belt control signals (DO). The 16 DO of 3HAC4776-1/1 module cannot meet the requirements and needs to be extended through DSTF610.

Connection logic:

The 12 channels of photoelectric sensor signals (workpiece positioning, in place detection) are connected to the 1-12 DI terminals of the DSTF610 terminal unit through wires. The DSTF610 is connected to the DI expansion interface of 3HAC4776-1/1 through TK520 cable, and the signals are synchronized to the IRC5 controller through the module;

The 14 control commands output by the controller (8 fixtures, 6 conveyor belts) are transmitted to the DO terminals 13-26 of DSTF610 through the module DO channel, thereby controlling the action of external actuators;

The emergency stop signal (ES) is directly connected to the dedicated safety DI channel (terminal 17) of the module, and when triggered, all DO outputs are immediately cut off to ensure the safety of personnel and equipment.

Core advantages: Through DSTF610 expansion, the problem of insufficient module DO channels is solved, and the isolation and protection function of DSTF610 is utilized to reduce the interference of external devices on robot signals; The system synchronization error is ≤ 0.8ms, and the assembly accuracy reaches ± 0.05mm, meeting the requirements of precision automotive component assembly.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-